4 Repair

4.4.5. Replacement of complete lower arm

283

3HAC026876-001 Revision: F

© Copyri

ght

200

7-2010 ABB.

All rights reserved.

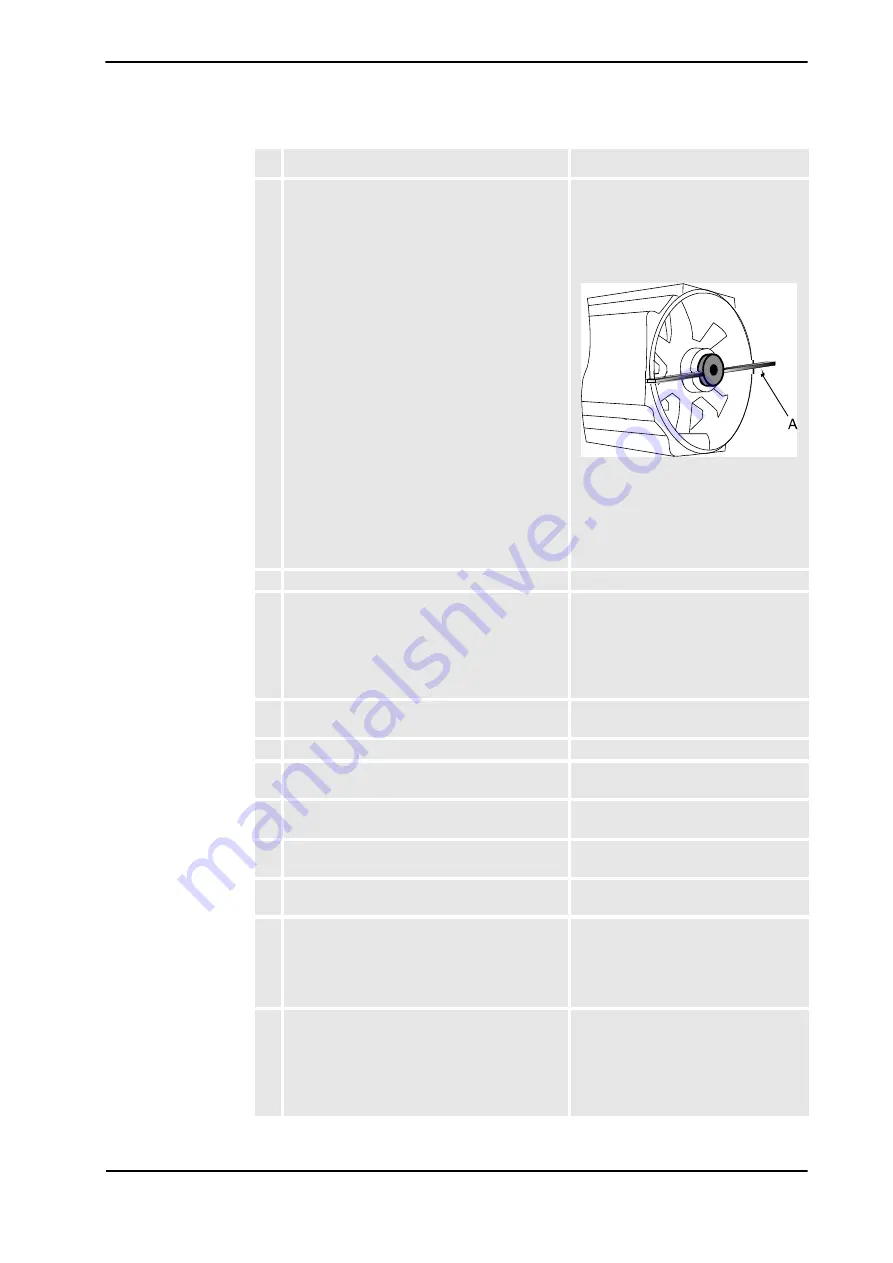

7. In case the hole pattern of the lower arm and

the gearbox axis 2 does not match, use power

supply to release the motor axis 2 brakes and

rotate the pinion and gear with the rotational

tool.

Connect power supply to connector

R2.MP2

•

+: pin 2

•

-: pin 5

xx0200000165

The rotation tool (A) is used beneath

the motor cover, directly on the motor

shaft as shown in figure above.

8. Disconnect the power supply, if used.

9. Secure the lower arm with 18 of the

20attachment screws and washers in gearbox,

axis 2.

20 pcs: M16 x 50, tightening torque:

300 Nm.

Reused screws may be used,

providing they are lubricated as

detailed in the section

before fitting.

10. Remove the guidings and secure the two

remaining screws as detailed above!

11. Remove the lifting tool from the lower arm.

12. Refit and restore the balancing device.

Detailed in section

Refitting of

balancing device

.

13. Refit the upper arm.

Detailed in section

.

14. Perform a leak-down test.

Detailed in section

15. Refill the gearbox with oil.

.

16. Refit and reconnect all cables inside the lower

arm.

Resecure any cable attachments.

Detailed in section

Detailed in section

cable harness, Cleanroom on page

224

17. Recalibrate the robot!

Calibration is detailed in a separate

calibration manual enclosed with the

calibration tools.

General calibration information is

included in the section

Calibration

information

.

Action

Note

Continued

Continues on next page