4 Repair

4.7.4. Replacement of gearbox, axis 6

385

3HAC026876-001 Revision: F

© Copyri

ght

200

7-2010 ABB.

All rights reserved.

Refitting, gearbox

The procedure below details how to refit gearbox, axis 6.

Action

Note

1.

DANGER!

Turn off all electric power, hydraulic and

pneumatic pressure supplies to the robot!

For Foundry Prime robots:

Do not turn off the air pressure to motors

and SMB.

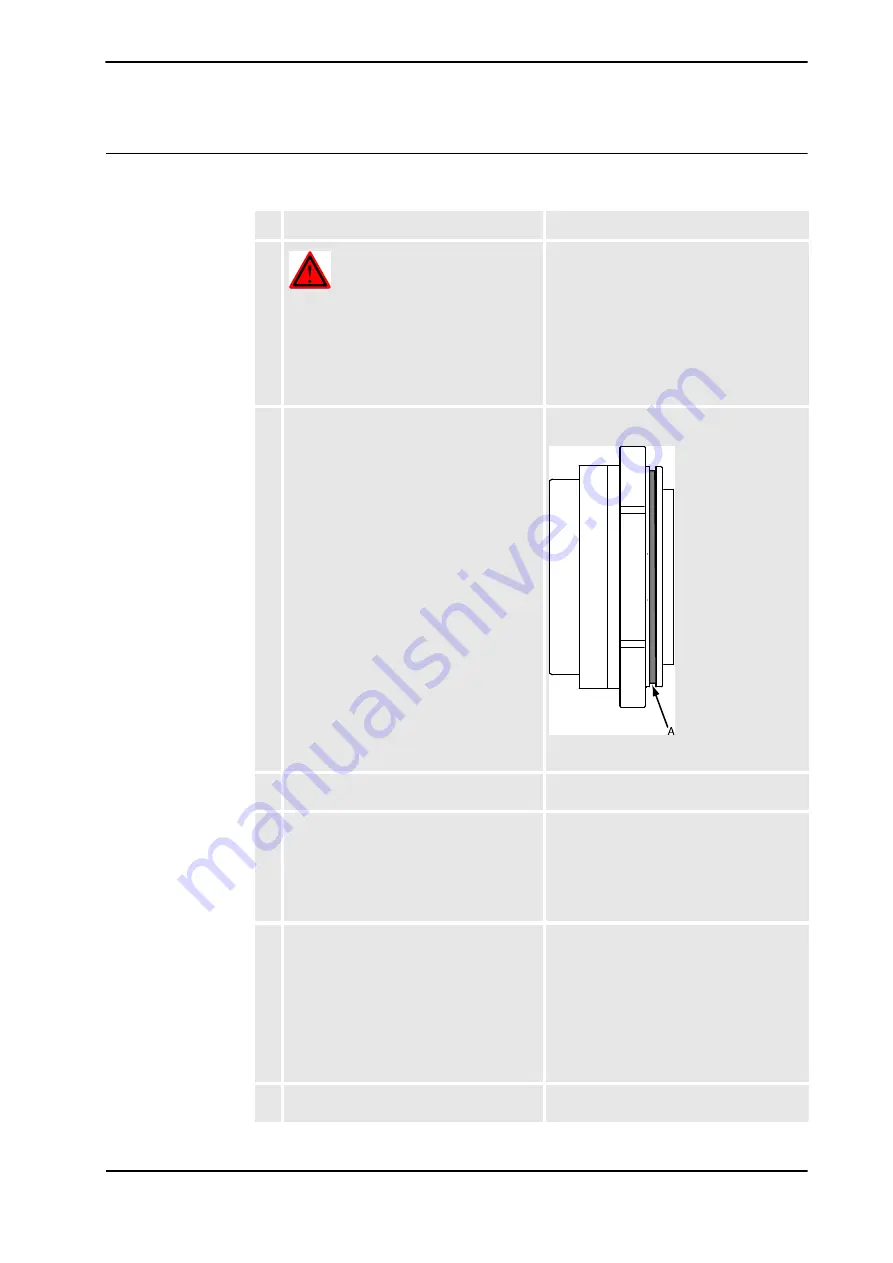

2. Make sure the o-ring is fitted to the rear of

the gearbox. Lubricate the o-ring with

grease.

Art. no. is specified in

.

xx0100000132

•

A: O-ring, gearbox axis 6

3. Release the holding brake of motor axis 6. Detailed in the section

.

4. Insert the gearbox, axis 6 into the wrist unit. Art. no. is specified in

.

Shown in the figure

.

Make sure the gears of the gearbox mate

with the gears of the motor!

5. Secure the gearbox with the attachment

screws and washers.

Shown in the figure

.

8 pcs or 18 pcs (depending on wrist

version): M8 x 40, 12.9 quality Gleitmo,

Tightening torque: 30 Nm.

Reused screws may be used, providing

they are lubricated as detailed in the

section

before

fitting.

6. Refit the turning disk.

Detailed in the section

Continued

Continues on next page