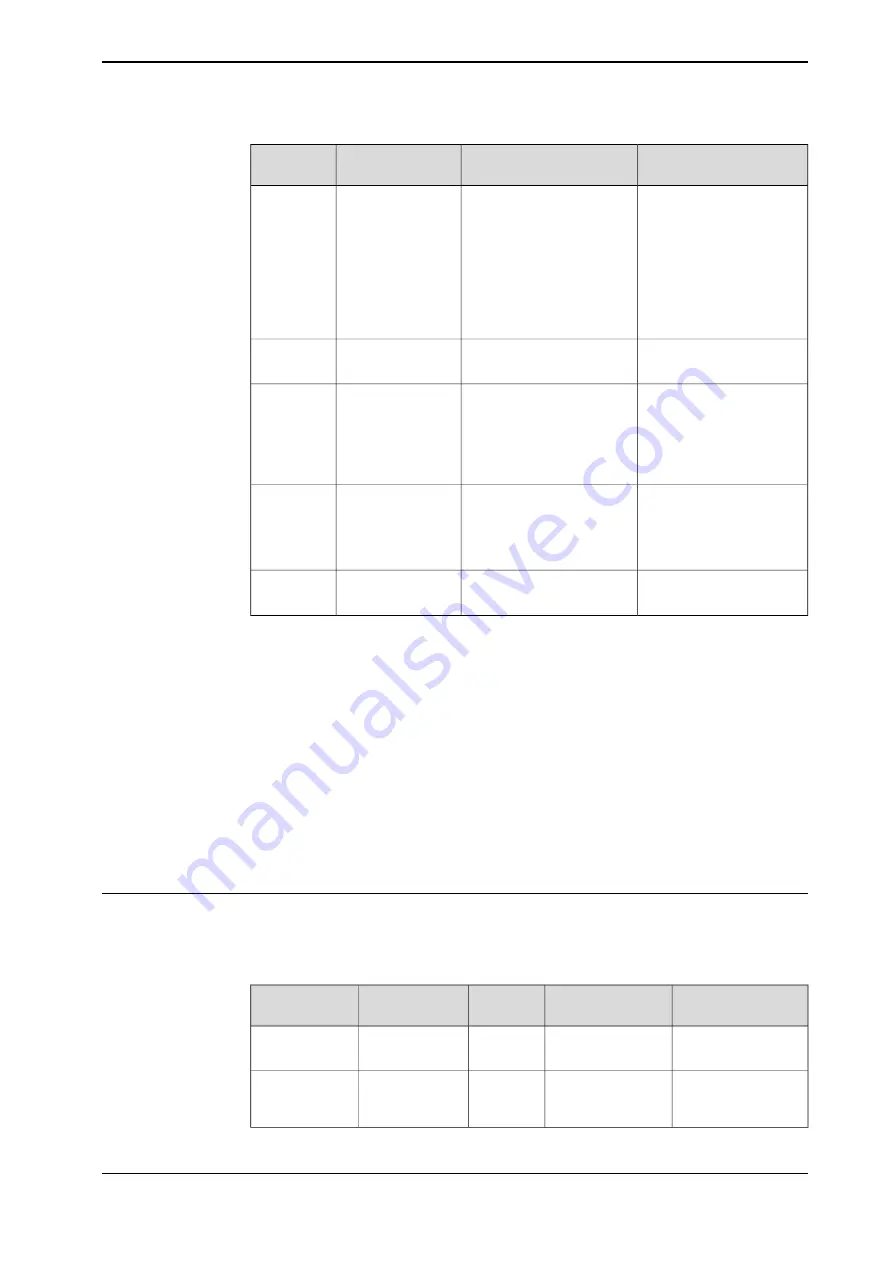

Detailed in section

Interval

Equipment

Maintenance

activity

Do not mix with other oils!

•

Changing oil, axis-6

gearbox on page 189

First change when DTC

reads:

6,000 hours

Oil in axis-6 gear-

box:

Kyodo Yushi TMO

150

Changing

Second change when DTC

reads:

24,000 hours

Following changes:

Every 24,000 hours

•

Expected compon-

ent life on page 131

Every:

40,000 hours

Robot

Overhaul

•

Replacing the SMB

battery on page 192

36 months or battery low

alert

iv

Battery pack,

measurement sys-

tem of type

RMU101 or

RMU102 (3-pole

battery contact)

Replacement

•

Replacing the SMB

battery on page 192

Battery low alert

v

Battery pack,

measurement sys-

tem with 2-pole bat-

tery contact, e.g.

DSQC633A

Replacement

Every:

Balancing device

bearings

Lubrication

12,000 hours

vi

i

Only valid for robots that are equipped with Type B motors.

Type B motors include evacuation on the motor flange to indicate failure of primary sealing between

the gearbox and the motor. Robots with protection type Foundry Plus have a sight glass installed

in the evacuation holes.

See

Type A vs type B motors on page 423

.

ii

Replace when damage or cracks is detected or life limit is approaching that specified in section

Expected component life on page 131

iii

DTC = Duty Time Counter. Shows the operational time of the robot.

iv The battery low alert (38213

Battery charge low

) is displayed when the battery needs to be replaced.

The recommendation to avoid an unsynchronized robot is to keep the power to the controller turned

on until the battery is to be replaced.

See the replacement instruction for more details.

v

The battery low alert (38213

Battery charge low

) is displayed when remaining backup capacity

(robot powered off) is less than 2 months. The typical lifetime of a new battery is 36 months if the

robot is powered off 2 days/week or 18 months if the robot is powered off 16 h/day. The lifetime

can be extended with a battery shutdown service routine. See

Operating manual - IRC5 with

FlexPendant

for instructions.

vi Always lubricate the front eye bearing after refitting the shaft of the balancing device.

Activities and intervals, optional equipment

The following table specifies the required maintenance activities and intervals for

common optional equipment. The maintenance of other external equipment for the

robot is detailed in separate documents.

Detailed in section

Note

Interval

Equipment

Maintenance

activity

Inspecting, signal

lamp on page 170

Every:

12 months

Signal lamp

Inspection

Inspecting the addi-

tional mechanical

stops on page 163

Every:

12 months

Mechanical stop

axes 1-2-3

Inspection

Continues on next page

Product manual - IRB 6650S

129

3HAC020993-001 Revision: Z

© Copyright 2004-2018 ABB. All rights reserved.

3 Maintenance

3.2.2 Maintenance schedule

Continued

Summary of Contents for IRB 6650S Series

Page 1: ...ROBOTICS Product manual IRB 6650S ...

Page 20: ...This page is intentionally left blank ...

Page 50: ...This page is intentionally left blank ...

Page 210: ...This page is intentionally left blank ...

Page 416: ...This page is intentionally left blank ...

Page 422: ...This page is intentionally left blank ...

Page 426: ...This page is intentionally left blank ...

Page 449: ......