Note

Action

Lift the upper arm and put it on the guide

pins.

3

24 VDC power supply

If the axis-3 motor is installed to the upper

arm:

4

Rotation tool

In order to release the brakes, connect the

24 VDC power supply.

Connect to R2.MP3-connector:

•

+ = pin 2

•

- = pin 5

Use the rotation tool and rotate the axis-3

motor to find the correct position for the

guide pins in the lower arm.

Pinion:

If the axis-3 motor is not installed to the

upper arm:

5

3HAC067546-001

i

Use the pinion to rotate the axis-3 gearbox

to find the correct position for the guide

pins in the lower arm.

3HAC067547-001

ii

3HAC067545-001

iii

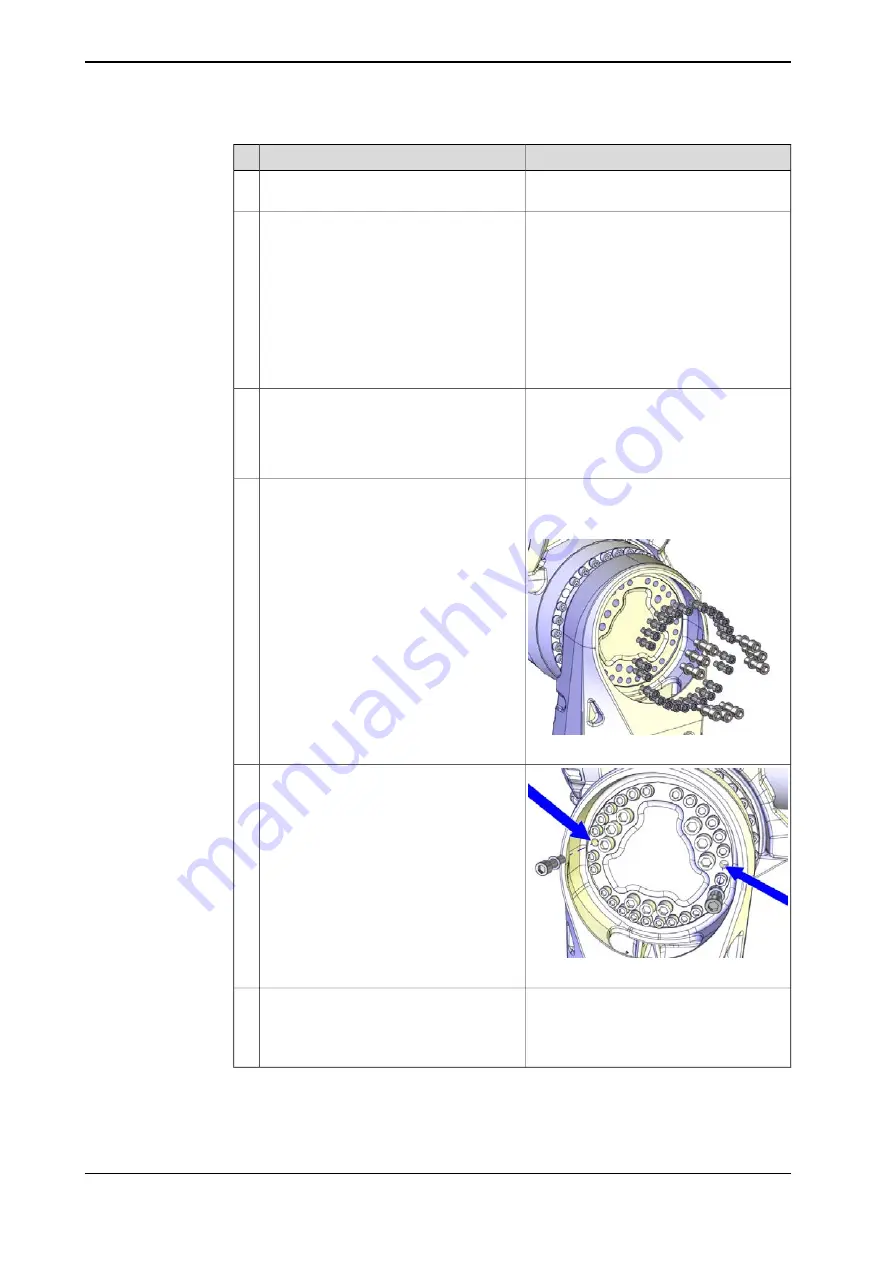

Screws:

Insert all nine M16 screws and 25 of the 27

M12 screws.

6

M16 (9 pcs)

M12 (25 of 27 pcs)

xx1400000359

xx1300000659

Remove the guide pins and fit the two re-

maining M12 screws.

7

Tightening torque depends on screw dimen-

sion.

Secure the upper arm by tightening the at-

tachment screws.

8

Tightening torque, M16: 300 Nm

Tightening torque, M12: 120 Nm

i

IRB 6700 - 235/2.65, IRB 6700 - 205/2.80, IRB 6700 - 175/3.05, IRB 6700 - 150/3.20

ii

IRB 6700 - 200/2.60, IRB 6700 - 155/2.85

iii

IRB 6700 - 300/2.70, IRB 6700 - 245/3.00

Continues on next page

320

Product manual - IRB 6700

3HAC044266-001 Revision: N

© Copyright 2013 - 2018 ABB. All rights reserved.

4 Repair

4.5.1 Replacing the upper arm

Continued

Summary of Contents for IRB 6700 Series

Page 1: ...ROBOTICS Product manual IRB 6700 ...

Page 46: ...This page is intentionally left blank ...

Page 110: ...This page is intentionally left blank ...

Page 786: ...This page is intentionally left blank ...

Page 812: ...This page is intentionally left blank ...

Page 836: ...This page is intentionally left blank ...

Page 838: ...This page is intentionally left blank ...

Page 845: ......