Note

Action

Connect the 24 VDC power supply to release the

brakes.

4

Connect to R2.MP1-connector:

•

+ = pin 2

•

- = pin 5

Note

Put the cables to the brake release tool through

the hole in the tool shelf.

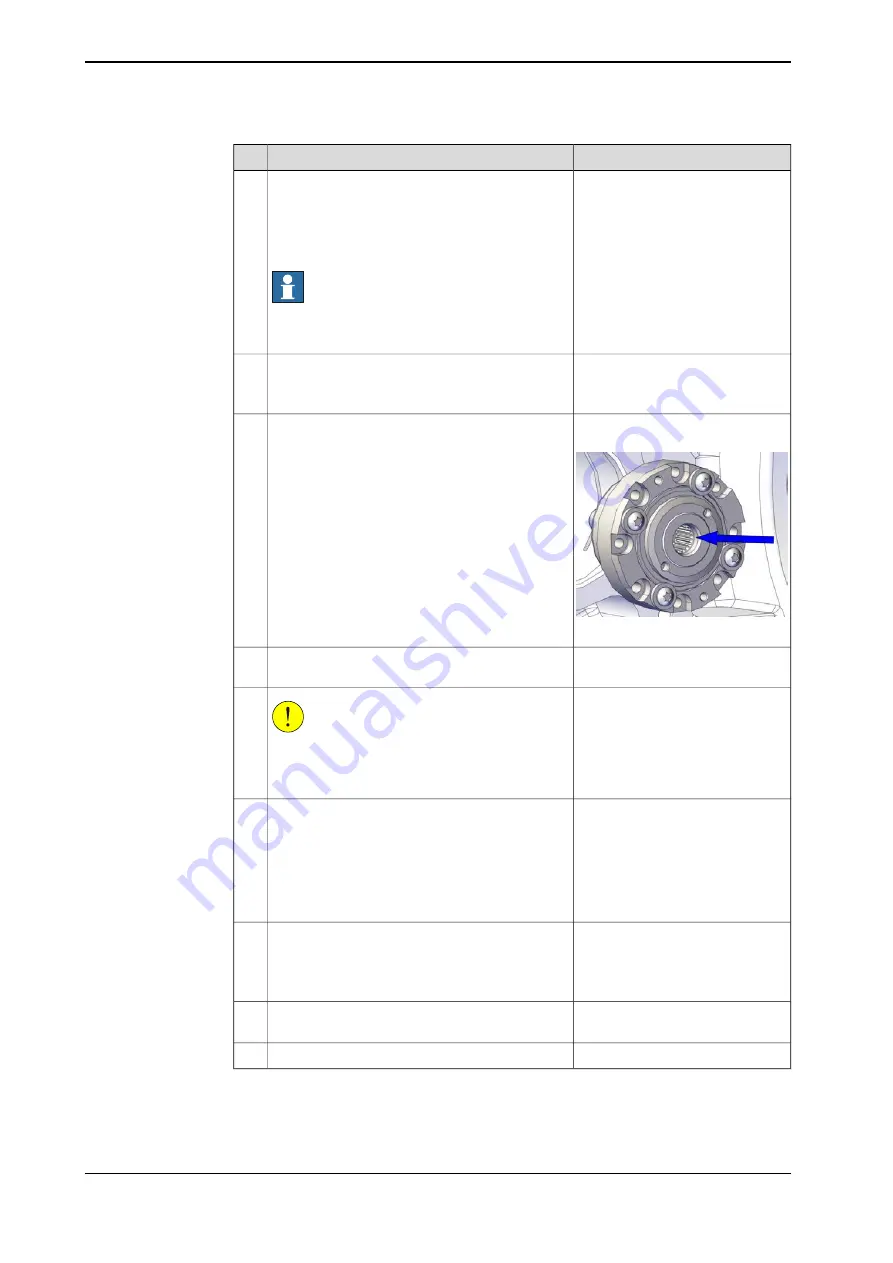

Guide pin, M10x150: 3HAC15521-

2

Fit guide pins in opposite holes.

5

Always use guide pins in pairs.

Grease: Castrol Molub. Alloy 777-

1 NG

xx1500002346

Apply 3 gram grease on the splines before fitting.

6

Put the motor on the tool shelf and rotate it into

position.

7

CAUTION

Whenever parting/mating motor pinion and hub,

the splines may be damaged if excessive force is

used.

8

Raise the revolving handle to assemble motor.

•

Make sure that the motor pinion is properly

mated into the hub.

•

Make sure that the motor pinion does not

get damaged.

•

Make sure that the direction of the cable

exit is facing the correct way.

9

Bits extender: 3HAC12342-1

Secure the motor with its attachment screws and

washers.

10

Tightening torque: 50 Nm.

Use a bits extender to reach the screws.

Screw dimension : M10x40 quality

12.9 Gleitmo (4 pcs)

See

.

Perform a leak-down test (if not already done).

11

Disconnect the 24 VDC power supply.

12

Continues on next page

550

Product manual - IRB 6700Inv

3HAC058254-001 Revision: L

© Copyright 2017 - 2020 ABB. All rights reserved.

4 Repair

4.8.1 Replacing the hub

Continued

Summary of Contents for IRB 6700Inv

Page 1: ...ROBOTICS Product manual IRB 6700Inv ...

Page 16: ...This page is intentionally left blank ...

Page 40: ...This page is intentionally left blank ...

Page 182: ...This page is intentionally left blank ...

Page 672: ...This page is intentionally left blank ...

Page 704: ...This page is intentionally left blank ...

Page 720: ...This page is intentionally left blank ...

Page 722: ...This page is intentionally left blank ...

Page 729: ......