2.3.2 Lifting robot with roundslings

General

The robot can be lifted with roundslings according to this section.

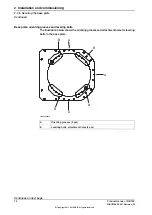

Sling specification

Length / Note

Lifting capacity

Qty

Sling type

0.460 m

4 000 kg

4 pcs

Chain sling with shortener

0.670 m (2 pcs)

0.790 m

1 m (2 pcs)

2 000 kg

5 pcs

Roundsling, robot

1.5 m

2 m (2 pcs)

Lifting with roundslings

Note

Action

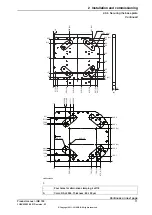

xx1000001093

Position robot in a secure transport position.

1

Attach roundslings to robot according to fig-

ure

2

CAUTION

The IRB 760 robot weighs 2300 kg.

All lifting accessories used must be sized

accordingly!

3

WARNING

Personnel must not, under any circum-

stances, be present under the suspended

load!

4

Continues on next page

62

Product manual - IRB 760

3HAC039838-001 Revision: M

© Copyright 2011-2018 ABB. All rights reserved.

2 Installation and commissioning

2.3.2 Lifting robot with roundslings

Summary of Contents for IRB 760 Series

Page 1: ...ROBOTICS Product manual IRB 760 ...

Page 8: ...This page is intentionally left blank ...

Page 46: ...This page is intentionally left blank ...

Page 96: ...This page is intentionally left blank ...

Page 144: ...This page is intentionally left blank ...

Page 394: ...This page is intentionally left blank ...

Page 400: ......

Page 401: ......