4 Repair

4.6.6. Replacement of motor, axis 6

3HAC022033-001 Revision: E

330

©

Co

py

rig

h

t 200

4 - 20

08 ABB.

All r

ig

h

ts r

e

se

rv

ed

.

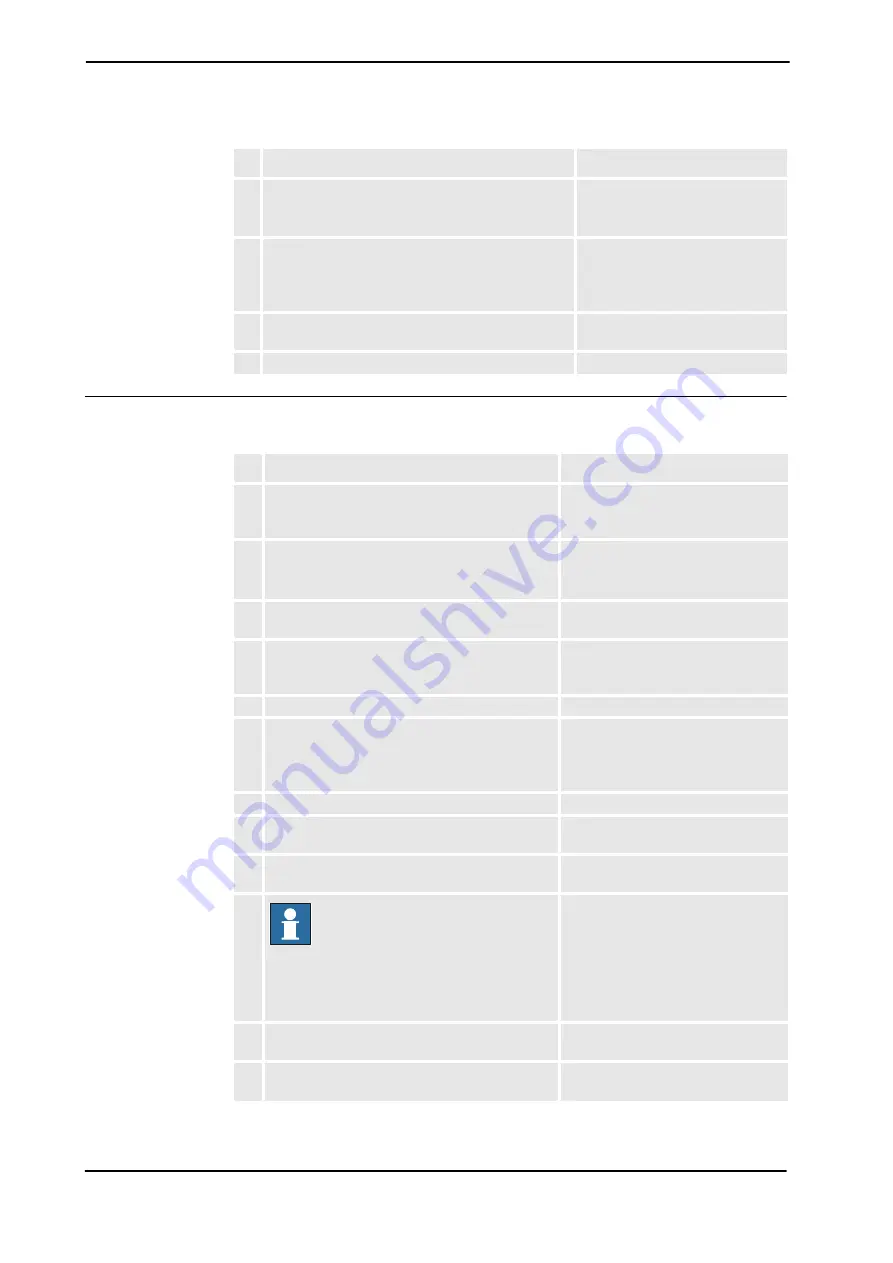

Refitting, motor

The procedure below details how to refit motor, axis 6.

7. Remove the motor by unscrewing its four

attachment screws and plain washers.

If required, use the extension 300mm for bits 1/2".

Art. no. is specified in

.

8. If required, press the motor out of position by fitting

removal tool, motor

to the motor attachment screw

holes.

Art. no. is specified in

.

Always use the removal tools in

pairs!

9. Lift the motor carefully to get the pinion away from

the gear and disconnect the brake release voltage.

Make sure the motor pinion is not

damaged!

10. Remove the motor by gently lifting it straight out.

Action

Note

Action

Note

1. Make sure the

o-ring

on the circumference of the

motor is seated properly. Lightly lubricate the o-

ring with

grease.

Art. no. is specified in

2. In order to release the brake, connect the 24

VDC power supply.

Connect to connector R3.MP6

•

+: pin 2

•

-: pin 5

3. Fit the two

guide pins

in two of the motor

attachment holes.

Art. no. is specified in

4. Fit the motor, with guidance from the pins,

making sure the motor pinion is properly mated

to the gear of gearbox, axis 6.

Make sure the pinion on the motor

shaft is not damaged!

5. Remove the guide pins.

6. Secure the motor with its four attachment screws

and plain washers.

If required, use

extension 300mm for bits 1/2"

.

4 pcs: M8 x 25, tightening torque: 24

Nm.

Art. no. is specified in

7. Disconnect the brake release voltage.

8. Reconnect all connectors beneath the motor

cover.

9. Refit the cover on top of the motor with its five

attachment screws.

Make sure the cover is tightly sealed!

10.

NOTE!

On Foundry Prime robots:

When changing motor, keep the cover from the

old motor.

11. Perform a leak-down test (if the gearbox has

been drained).

Detailed in section

12. Refill the gearbox with oil, if it has been drained. Detailed in section

.

Continued

Continues on next page