Note

Action

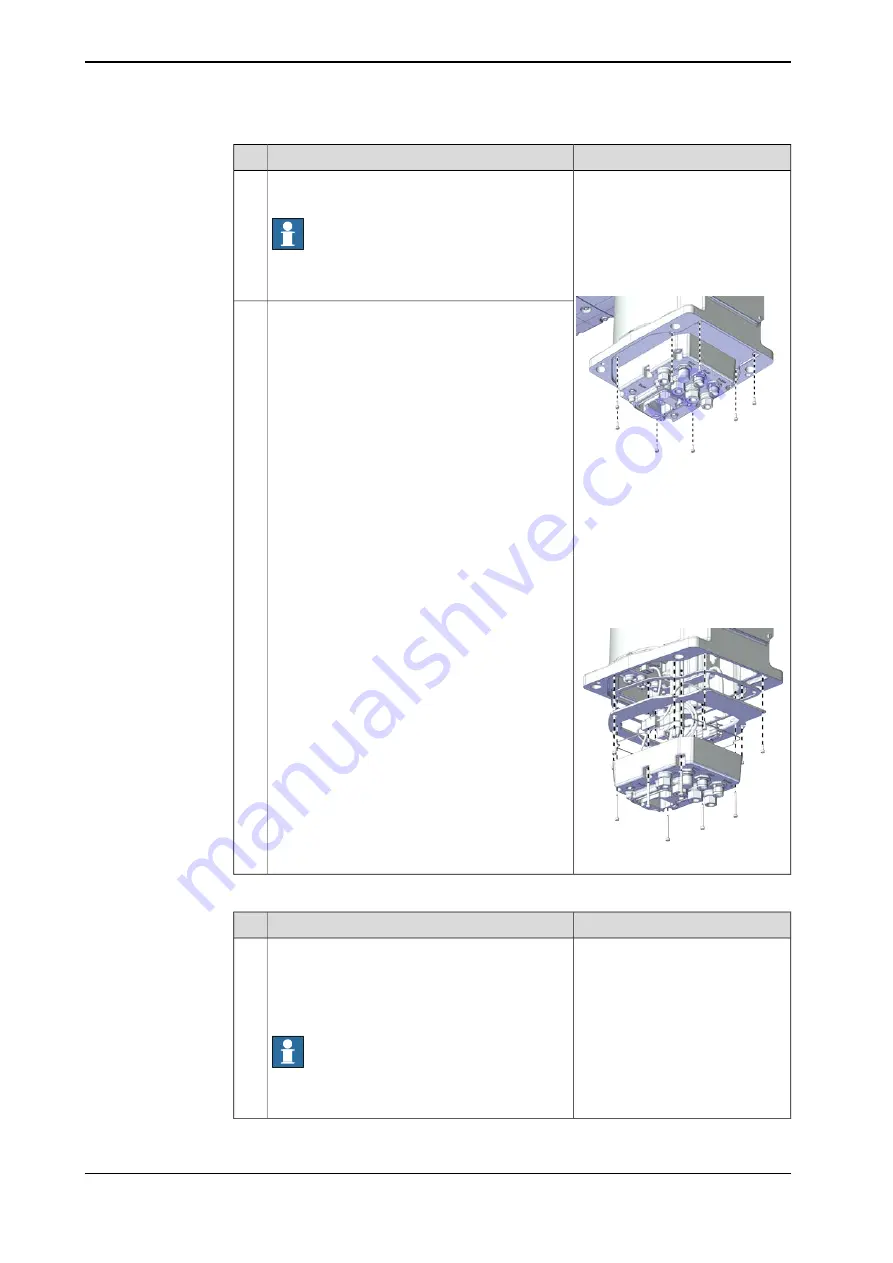

For undeneath outlet cable version:

For undeneath outlet cable version, refit the main

harness assembly to the base.

Note

Refit the bottom plate to the main harness if

needed.

5

For robots with protection class

IP30 (option 3350-300)

Screws: Hex socket head cap

screw M3x30 12.9 Lafre

2C2B/FC6.9 (8 pcs)

Tightening torque: 1.2 Nm ±10%

xx2100001204

Secure with the screws.

6

For robots with protection class

IP54 (option 3350-540)

For robots with protection type

Clean Room (option 3351-1)

Screws: Hex socket head cap

screw M3x30 12.9 Lafre

2C2B/FC6.9 (8 pcs)

Tightening torque: 1.2 Nm ±10%

xx2100002437

Refitting the base plate/ rear plate

Note

Action

For robots with protection type Clean Room:

1

Clean the joints that have been opened and wipe

the parts free from particles with spirit on a lint

free. See

Cut the paint or surface on the robot

before replacing parts on page 118

Note

After all repair work, wipe the Clean Room robot

free from particles with spirit on a lint free cloth.

Continues on next page

752

Product manual - IRB 920

3HAC075721-001 Revision: C

© Copyright 2022 ABB. All rights reserved.

5 Repair

5.7.1 Replacing the axis-1 motor sub-assembly

Continued

Summary of Contents for IRB 920

Page 1: ...ROBOTICS Product manual IRB 920 ...

Page 8: ...This page is intentionally left blank ...

Page 14: ...This page is intentionally left blank ...

Page 50: ...This page is intentionally left blank ...

Page 110: ...This page is intentionally left blank ...

Page 984: ...This page is intentionally left blank ...

Page 1000: ...This page is intentionally left blank ...

Page 1002: ...This page is intentionally left blank ...

Page 1006: ......

Page 1007: ......