3.4 Activities 1 month

3.4.1 Inspecting the automatic lubrication system

Overview

There is an automatic lubrication system in IRBT 2005. An electric pump will deliver

the correct quantity of grease from a cartridge to the ball bearing blocks and to the

pinion at required time intervals (one cycle per day). The grease is pushed in the

piping by the pump; a valve is sequencing the distribution to each port.

The level of the lubricant should be inspected once a month, even though the

system should apply the lubricant equally over a longer period.

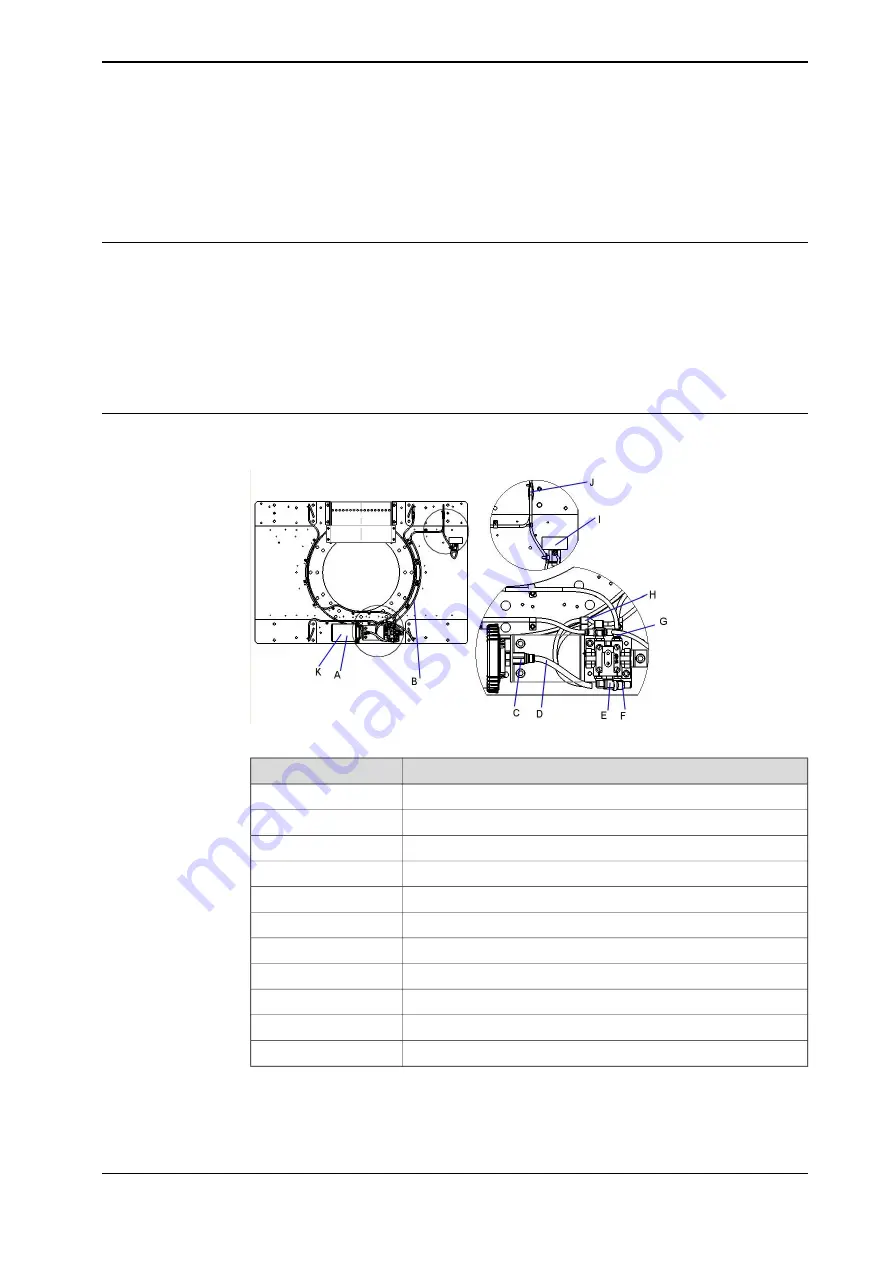

Location of lubrication system

The lubrication system is located as shown in the figure.

xx1400000478

Description

Pos

Lubrication pump EPS 240

A

Polyamide tube 4x6

B

Straight adaptor F1/4-D8

C

Polyamide tube 6x8

D

Male stud elbow (white brass) D8 G1/4

E

Male stud elbow (white brass) D6 G1/8

F

Male stud straight (white brass) D6 G1/8

G

Y fitting D6-D6

H

Inline fitting-D6

I

Felt gear set

J

Grease package 240 CC

K

Continues on next page

Product manual - IRBT 2005

159

3HAC051130-001 Revision: F

© Copyright 2015 - 2018 ABB. All rights reserved.

3 Maintenance

3.4.1 Inspecting the automatic lubrication system

Summary of Contents for IRBT 2005

Page 1: ...ROBOTICS Product manual IRBT 2005 ...

Page 8: ...This page is intentionally left blank ...

Page 44: ...This page is intentionally left blank ...

Page 148: ...This page is intentionally left blank ...

Page 284: ...This page is intentionally left blank ...

Page 286: ...This page is intentionally left blank ...

Page 289: ......