Note

Action

xx1400002584

Make sure that the robot is in its shipping position.

If not there is a risk that the robot will tip over

when the remaining screws are removed, resulting

in injury or damage.

•

Axis-1: -90° or +90°

•

Axis-2: -65°

•

Axis-3: +2°

•

Axis-4:

•

Axis-5: +90°

•

Axis-6: -90°

Note

The figure shows the shipping position of an un-

dressed robot. It the robot id dressed, this must

be taken in consideration when the robot is lifted.

2

DANGER

Turn off all:

•

electric power supply

•

hydraulic pressure supply

•

air pressure supply

to the robot, before entering the robot working

area.

3

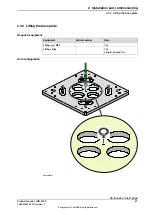

Verify that the fork lift accessory set is properly

attached and secured before lifting.

4

Lifting the robot

Note

Action

DANGER

Make sure that all supplies for electrical power,

hydraulic pressure, and air pressure are turned

off.

1

xx1500002296

Release the torque on the remaining screws that

secure the robot to the foundation.

DANGER

DO NOT unscrew the attachment screws com-

pletely, but only a few millimeters. At this point,

the remaining screws are used as a safety meas-

ure, until the forks of the truck has been inserted

into the fork lift accessory pockets.

2

Continues on next page

62

Product manual - IRB 8700

3HAC052853-001 Revision: F

© Copyright 2015-2018 ABB. All rights reserved.

2 Installation and commissioning

2.3.1 Lifting the robot with fork lift accessory set installed

Continued

Summary of Contents for IRC5 Compact

Page 1: ...ROBOTICS Product manual IRB 8700 ...

Page 16: ...This page is intentionally left blank ...

Page 824: ...This page is intentionally left blank ...

Page 838: ...This page is intentionally left blank ...

Page 840: ...This page is intentionally left blank ...

Page 846: ......

Page 847: ......