4.2.2 Maintenance schedule

Scheduled and non-predictable maintenance

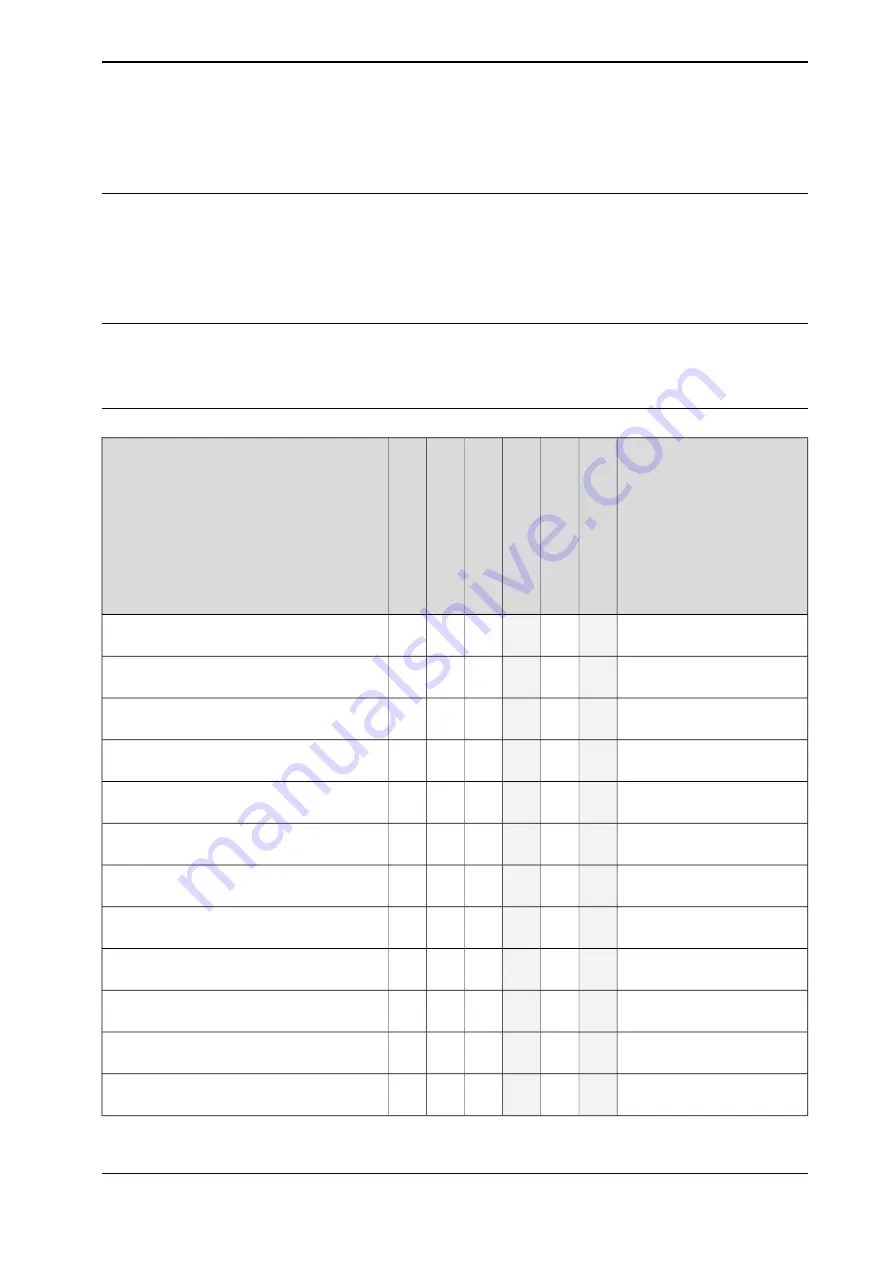

The product must be maintained regularly to ensure proper function. The

maintenance activities and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the product. Any damage

must be attended to immediately.

Life of each component

The inspection intervals

do not

specify the life of each component. Values for these

are specified in the section

Expected component life on page 183

Maintenance schedule

Reference

Every

100

km

Every

36

months

Every

12

months

Every

6

months

Every

1

months

Regularly

Maintenance activities

x

Cleaning the whole system

x

Inspecting the information labels

x

Inspecting the lubrication system

x

Inspecting the cable chain

Inspecting the levelling screw

x

Inspecting the leveling screw

Inspecting the rectangular rails

x

Inspecting the rectangular rails

Inspecting the cam roller units

x

Inspecting the cam roller

x

Inspecting the felt wiper

x

Inspecting the cables and connectors

x

Inspecting the mechanical stops

x

Inspecting the gearbox, back lash

x

Cleaning and lubricating the gear racks

Continues on next page

Product manual - IRT 710

181

3HKA00000186299-001 Revision: B

© Copyright 2023 ABB. All rights reserved.

4 Maintenance

4.2.2 Maintenance schedule

Summary of Contents for IRT 710

Page 1: ...ROBOTICS Product manual IRT 710 ...

Page 14: ...This page is intentionally left blank ...

Page 58: ...This page is intentionally left blank ...

Page 84: ...This page is intentionally left blank ...

Page 360: ...This page is intentionally left blank ...

Page 364: ...This page is intentionally left blank ...

Page 378: ...This page is intentionally left blank ...

Page 380: ...This page is intentionally left blank ...

Page 383: ......