IB 6.2.11.1-2C

Page 16

ABB

Shunt Trip Device (See Figure 8).

a. Turn trip rod (2, Figure 8) down until circuit breaker

does not trip with plunger (3) held down.

b. Close circuit breaker.

c. Push plunger (3) down as far as possible and hold in

this position while turning up trip rod (2) until circuit

breaker just trips.

d. Turn rod (2) up approximately 2½ to 3 turns.

FIELD TESTING THE MPSC-2000 SOLID

STATE TRIP SYSTEM

There are two ways to evaluate the MPSC-2000 solid

state trip system: primary current injection through the

breaker main contacts; and secondary current injection

directly into the trip device. Either method will test the

trip device; primary injection has the advantage of

testing the current sensors and magnetic latch also.

The following is a procedure for performing this field

testing.

Notes:

1. Refer to time current curves TD-9651, TD-9652, and

TD-9653.

2. When checking calibration, disable the functions not

being tested, or set them at their highest threshold and

delay values.

It is especially important to disable

the Ground function when testing the other

elements to prevent false tripping.

5. Reference bulletin IB 6.1.2.8-1A for instructions on

setting the MPSC-2000.

6. These procedures are written for primary injection. If

the trip device is being tested by secondary current

injection, contact ABB for special instructions and/or

test equipment.

7. The term “Range Selection” is used herein for

consistency with previous MPS-type devices, and

refers to the value of the “Rating” setting of the device.

Like the previous MPS-type devices, the MPSC-2000 is

capable of operating at two basic ratings: one equal to

the maximum frame continuous current rating of the

breaker-mounted current sensors, and one equal to

half the frame rating. For example, on an 4000A

breaker with 4000A sensors, the MPSC-2000 rating

can be set to 4000A or 2000A. When the rating is

changed, other available settings are scaled

accordingly; thus the term “Range Selection”.

Instantaneous or Short Time Threshold Test

1. Either disable the trip elements not being tested, or

set them to their highest threshold value. Set the Long

Time Delay to its maximum setting. Set the Short Time

delay to its minimum setting for Short Time tests.

2. It is recommended that the Range Selection be set

to its lowest value to minimize the current required for

this test; however, it may be set to either available

value.

3. Set the threshold and delay of the trip element being

tested (again, it is recommended that a low value be

used).

4. Test for the actual threshold by increasing test

current until the breaker trips. It is important to

increase the current fast enough so that the breaker will

not be tripped by the Long Time element prior to

completion of the test.

5. The threshold tolerance is +/- 10% on all selector

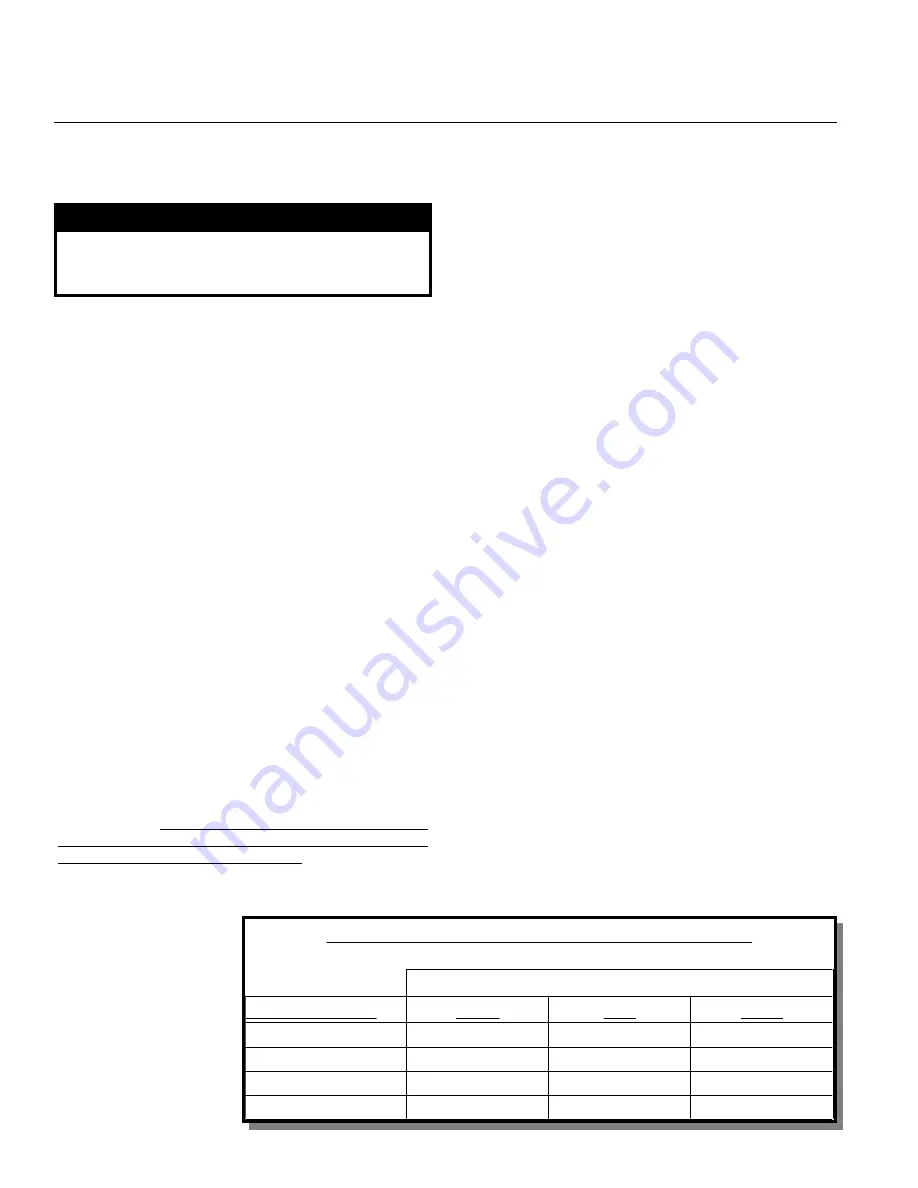

Table 4 - MPSC-2000 Typical Delay Bands

Delay Times (sec.)

Trip Element

Min.

Int.

Max

Long Time

8-13

20-33

61-100

Short Time (DEF)

0.080-0.170

0.200-0.320

0.350-0.500

Short Time (IIT)

0.160-0.250

0.520-0.780

0.910-1.350

Ground Trip (IIT)

0.05-0.17

0.20-0.32

0.35-0.50

3. The circuit breaker

must be closed before

each test below.

4. Following each test,

check the MPSC-2000

event register to ensure

that the correct element

tripped the breaker,

especially if test results

appear to be incorrect.

WARNING WARNING WARNING WARNING

RISK TO PERSONNEL AND FIRE CAN RESULT IF

THE CIRCUIT BREAKER IS ENERGIZED WITHOUT

THE HARNESS PLUG AND SCREWS IN PLACE.