10

KM26 |

MAGNETIC LEVEL GAUGE | OI/KM26-EN REV I

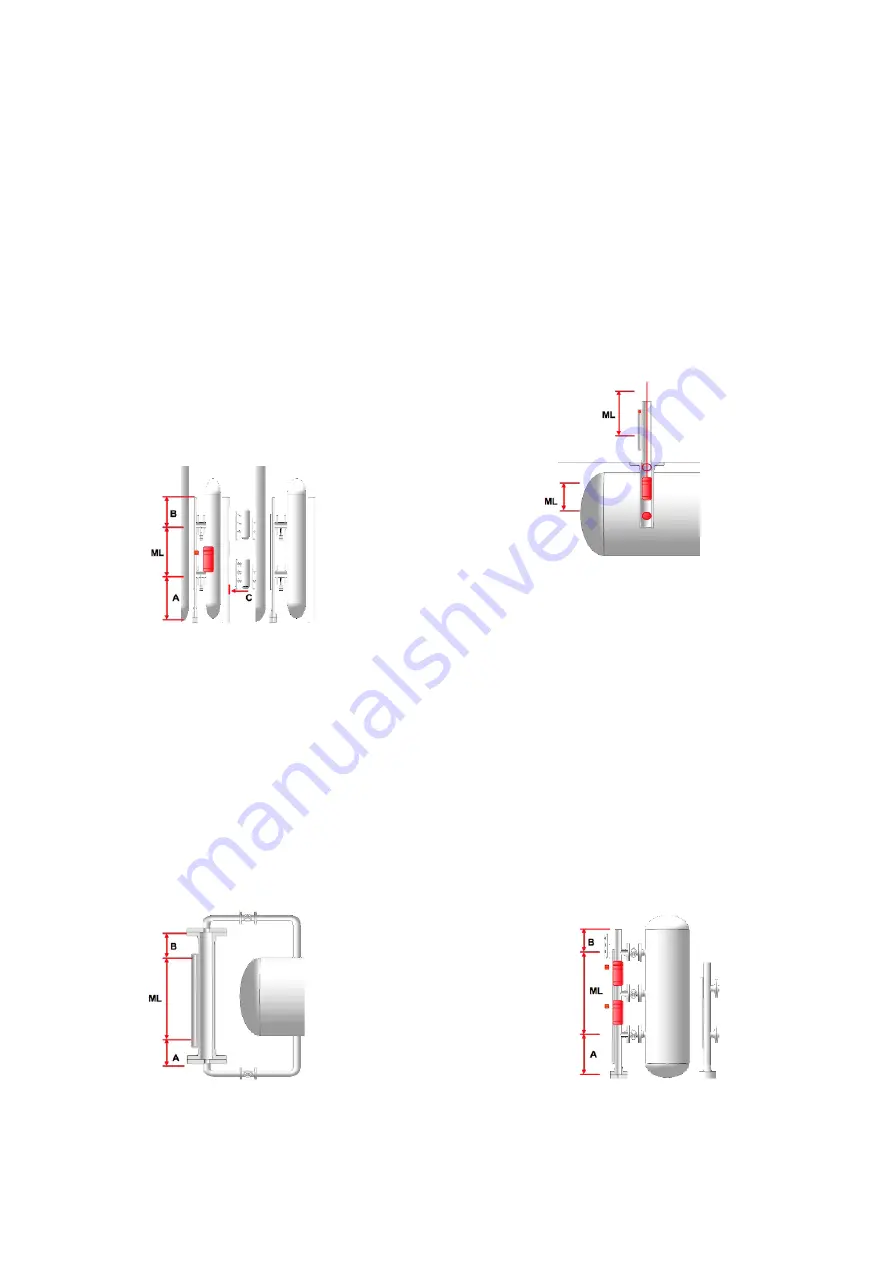

MLG configurations

There are several configurations for the KM26. The major

configurations are described in this section.

Side Mount

The side mount MLG is referred as the KM26S model which is

the most common configuration. In its simplest configuration

it contains two process connections, a fluid-filled chamber

with flanges and/or caps on the top and bottom, a float, and

a visual indicator. Depending on the tank/vessel height there

can be up to six side process connections.When the liquid

level in a vessel changes, the corresponding level in the MLG

chamber changes as liquid moves through the process

connections located at the top and bottom of the desired

indication range.

Top and Bottom

This configuration has process connections at the top and

bottom of the chamber, which are connected to the vessel

through additional piping. The top and bottom mount is

commonly used in spherical-shaped vessels which are filled at

the top and emptied from the bottom of the vessel. The

chamber usually spans the entire height of the vessel and

does not require additional space above the vessel which can

be used in tight plant layouts.

Top Mount

The top mount MLG is also known as the KM26T which is

commonly used for sumps and underground tanks that do

not have side connection access. In its simplest form, a top

mount consists of a chamber with a single flange at the

bottom and a cap at the top. A float assembly hangs below

the chamber into the liquid via a guide rod. The float

assembly consists of a magnet at the top of a guide rod and a

float at the bottom. As the float itself does not contain any

magnet in this configuration, this is also used in applications

where the liquid contains magnetic particles. A stilling well,

can also be used within the vessel to prevent bending of the

rod during maintenance, installation, agitation, or when

turbulence or flow may be present in the tank during

operation.

Dual Level

In tanks containing two or more liquids, the KM26 MLGs are

able to measure the interface level between two liquids.The

chamber is capable of housing two floats simultaneously. The

interface float is sized and weighted so that it sinks through

the upper liquid layer and floats on the lower liquid. This

allows the magnets to position precisely at the point of

interface. The other float is weighted to operate at the

specific gravity of the upper liquid, measuring the total level.

For these kind of applications, its always recommended to

have at least three side process connections to ensure reliable

interface measurement. In this case, shuttle indication is

required for proper operation. Shuttle 1 is magnetically

coupled to float 1 and shuttle 2 is magnetically coupled to

float 2.

Other Configurations

KM26 is offered in other configurations like top and side, side

and bottom.

. . . 3 Mounting

Figure 7 - side mount configuration

Figure 8 - top and bottom configuration

Figure 10 - dual level configuration

Figure 9 - top mount configuration