This retrofitting kit is designed for replacing the KP-800 800A, KP-1600 1600A, or KP-2000 2000A air circuit breaker

in the KP-line switchgear. It allows an Emax 2 withdrawable air circuit breaker of the same size as indicated in Table

A to be attached to the original switchgear cradle assembly and racked into the switchgear enclosure.

IMPORTANT !

Retrofitting allows an obsolete control and protection device to be replaced, but does not allow the ratings of the

original switchboard to be altered in any way.

The retrofitting kits are dimensioned and validated for the obsolete device performances which may be lower than the

new Emax 2 ratings.

Consult ABB for further details.

Full correspondence of the electrical characteristics is guaranteed (rated current excluding derating if indicated in the

table, and breaking capacity) so long as the kit is chosen in accordance with the indications in the ABB technical

catalogues dedicated to retrofitting products. The kit has been designed also to preserve the insertion/extraction

operations functionality and the optional auxiliary (secondary) circuits of the obsolete circuit breaker. The CiC is

installed and then locked on the switchgear cradle, thus making use of the of its plug-in features as established in the

operation and maintenance manual of the new Emax 2 circuit breaker without having to modify any of the live parts

of the switchgear.

ATTENTION !

The instructions concern the sole assembly of the retrofitting kit. They do not substitute for the instruction in the

installation, operation, and maintenance manual of the Emax 2 circuit breaker installation instructions document

number, 1SDH001000R0002.

If optional auxiliary (secondary) circuits are required, refer to section 12.

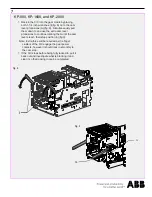

Structure Details

The fixed part of the new Emax 2 is mounted to a steel sheet structure (CiC) that is then mounted into the KP-line

switchgear cell. The Emax 2 cradle is fitted with custom silver flashed copper run backs and finger clusters that align

to and mate with the existing KP-line switchgear power circuit stabs. The entire assembly mounts on the original K-

line cell rails. No additional phase barriers were required for this CiC. The weight of the low voltage cradle-in-cradle

assembly is listed in table B.

Doc. N.° 2TSA451037P0000 REV A

KP-800, KP-1600, or KP-2000 TO EMAX 2

n

2TSA451021P0000

Retrofitting between KP-800 800A, KP-1600 1600A, or KP-2000 2000A, and an Emax

circuit breaker with a cradle-in-cradle (CiC) adapter.

CiC Model

Weight (lbs./kg)

KP-800

160/73

KP-1600

200/91

KP-2000

235/107

Table B

Table A

RATING

EMAX 2

RATING

KP-800

800A

E-2.2 (S)

800A

KP-1600

1600A

E-2.2 (S)

1600A

KP-2000

2000A

E-4.2 (V)

2000A