10

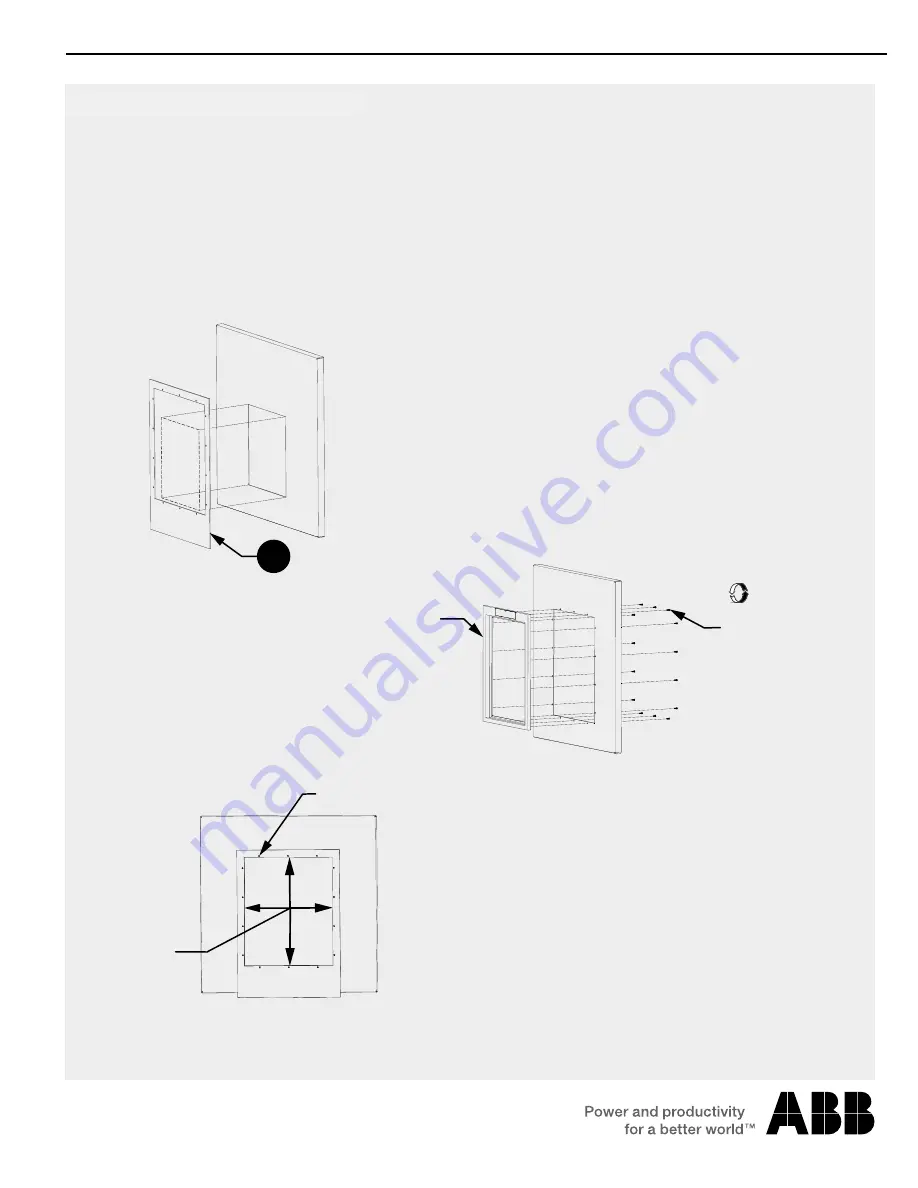

Fig. 13

•

To make it easier to make the hole in the existing switchgear door, the kit

comes complete with an adhesive template for attaching as shown (fig. 13).

•

See 2TSE431186P1000.

•

Position the template by aligning the dotted lines with the existing cut out.

•

Cut the door along the unbroken line and drill holes in the positions marked

by the holes (fig. 14).

•

Mount the dust guard escutcheon (s)(fig. 15) provided with the breaker to the

door.

1B

Fig. 15

Cut lines

14x 0.2 in (5 mm)

Ø

Fig. 14

s

KP-800, KP-1600, and KP-2000

13.28 lb in

(1.5 Nm)

NOTE: If the dotted line on the adhesive template fails to perfectly match the existing opening in the door, refer to the

instructions for installing the dust guard escutcheon provided with the circuit breaker.