OI-LLT100-EN Rev. D |

User Guide

13

4.4 Presenting the first level of configuration

menus

Once you enter in the configuration menus, pressing the

Down arrow key will navigate through the various menus in the

following order:

–

Easy Setup

–

Device Setup

–

Display

–

Process Alarm

–

Calibrate

–

Diagnostics

–

Device Info

–

Communication

4.5 Presenting the first level of operator menus

Once you enter in the operator menus, pressing the Down

arrow key will navigate through the various menus in the

following order:

–

Diagnostics

–

Operator Page 1

–

Operator Page 2

–

Operator Page 3

–

Operator Page 4

–

Signals View

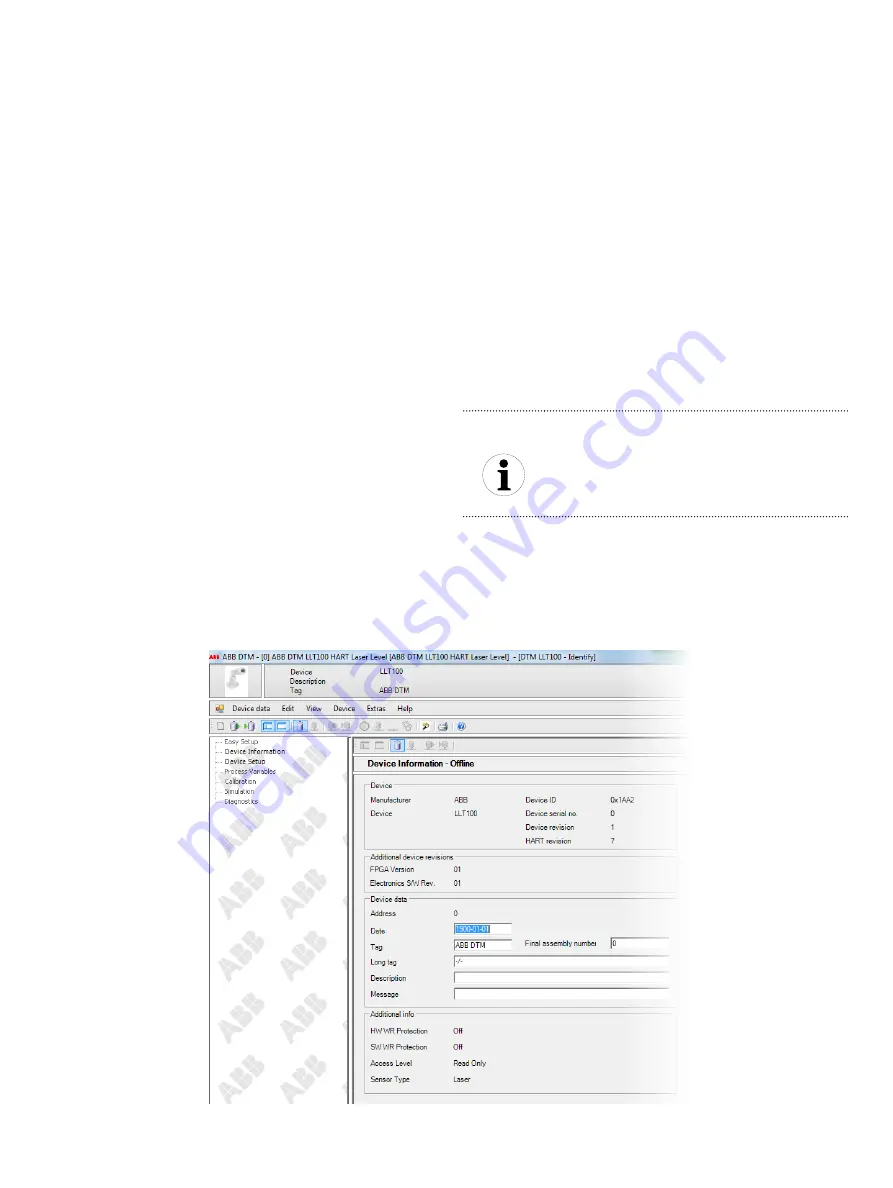

4.6 Introducing HART Communication

The HART communication protocol (

H

ighway

A

ddressable

R

emote

T

ransducer) is a hybrid analog and digital industrial

automation protocol. Its most notable advantage is that it

allows remote configuration of LLT100 instruments over legacy

4 – 20 mA analog device current loops, sharing the pair of

wires used by analog-only host systems.

ABB provides a HART communication package for the LLT100.

Once installed in your preferred HART application, it will allow

communication with your LLT100 instruments.

The ABB HART communication package (

RevXX.XX.XX_

XX.XX.XX

) is located in the folder whose name ends with

DTM_LLT100_HART_Laser_Level

.

NOTICE

The communication board for HART (behind the

interface board) can not be replaced in the field, and

can not be moved between LLT100 instruments. In case

of failure, the LLT100 instrument must be sent back to

ABB for calibration and repair.

Figure 14

Typical DTM (HART) screen for the LLT100

Summary of Contents for LLT100

Page 8: ...This page intentionally left blank ...

Page 10: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 22: ...This page intentionally left blank ...

Page 26: ...This page intentionally left blank ...

Page 44: ...This page intentionally left blank ...

Page 50: ...This page intentionally left blank ...

Page 66: ...This page intentionally left blank ...

Page 67: ......