LMT10 0 A N D LMT 20 0 |

M AG N E TOS T R I C T I V E L E V EL T R A N SM I T T ER S | FF O I/L M T 10 0/ 2 0 0/FF - EN R E V. A

5

1 Introduction

This manual is designed to provide information on installing,

operating and troubleshooting the LMT Series of level

transmitters This LMT Series is comprised of the LMT100 and

LMT200 models

Every section of this manual is dedicated to the specific phases

of the LMT lifecycle The start of the lifecycle begins with the

receipt of the transmitter and its identification and continues

through installation, the connection of all electrical

components, the configuration of the device and finally ends

with the troubleshooting and maintenance operations

Product description

The LMT Series of level transmitters is a modular range of field

mounted, microprocessor-based electronic transmitters,

utilizing multiple sensor technologies Accurate and reliable

measurement of liquid levels is provided in even the most

difficult and hazardous industrial environments The LMT

Series can be configured to provide specific industrial output

signals, according to Fieldbus digital communication The LMT

Series consists of two models (LMT100 & LMT200):

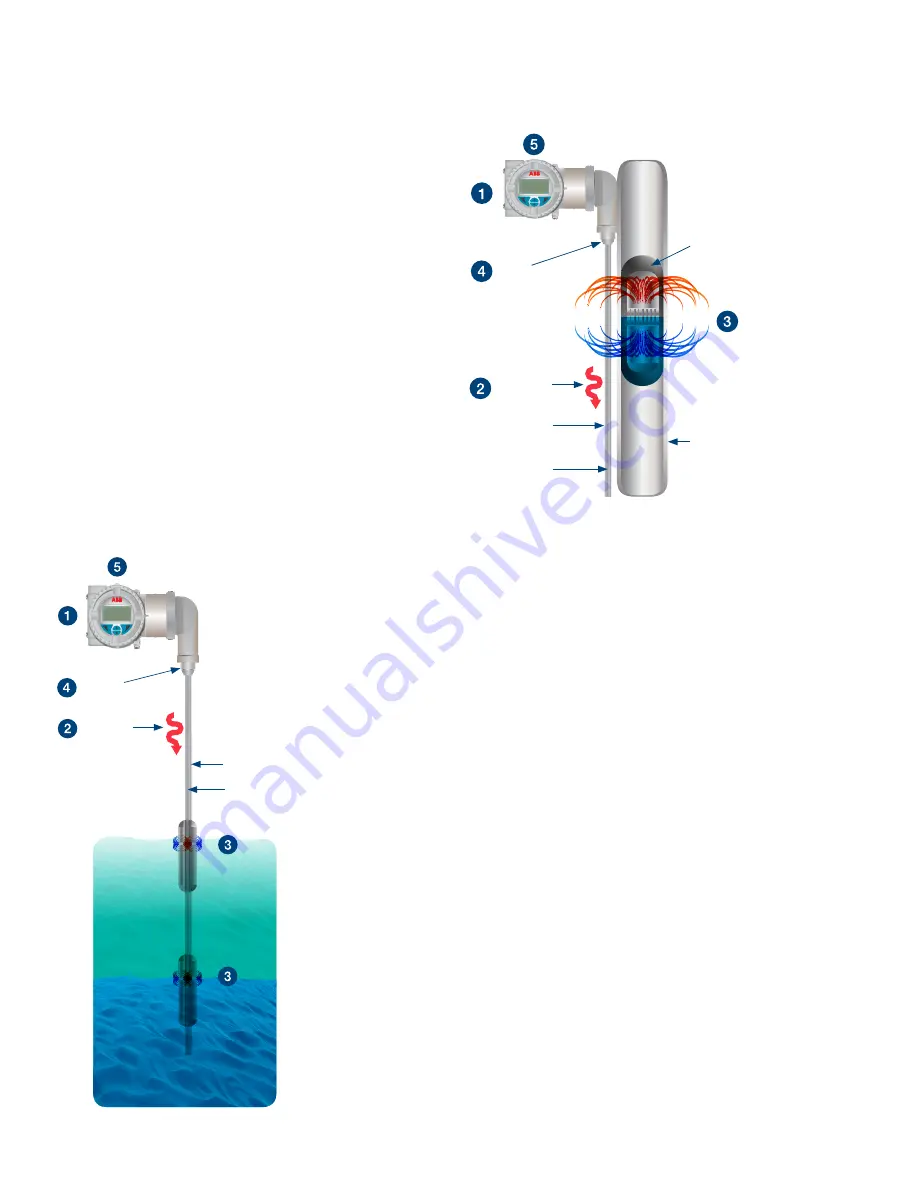

Sensor

Sensor Wire

Sensor Tube

Current

pulse

Figure 1 LMT100 (insertion-mounted)

Sensor

Sensor

wire

Current

pulse

Magnetic float

assembly

Sensor

tube

Gauge (KM26)

Figure 2 LMT200 mounted on gauge (KM26)

The LMT Series is based upon the magnetostrictive principle

1 The device electronics generates a low energy current pulse

at fixed intervals

2 The electrical pulses create a magnetic field which travels

down a specialized wire inside the senor tube

3 The interaction of the magnetic field around the wire and the

magnetic float causes a torsional stress wave to be induced

in the wire This torsion propagates along the wire at a

known velocity, from the position of the magnetic float and

toward both ends of the wire

4 A patented sensing element placed in the transmitter

assembly converts the received mechanical torsion into an

electrical return pulse

5 The microprocessor-based electronics measures the elapsed

time between the start and return pulses (Time of Flight)

and converts it into a position measurement which is

proportional to the level of the float