LMT S E R I E S |

M AG N E TOS T R I C T I V E L E V EL T R A N SM I T T ER | O I/L M T 10 0/ 2 0 0 - EN R E V. B

13

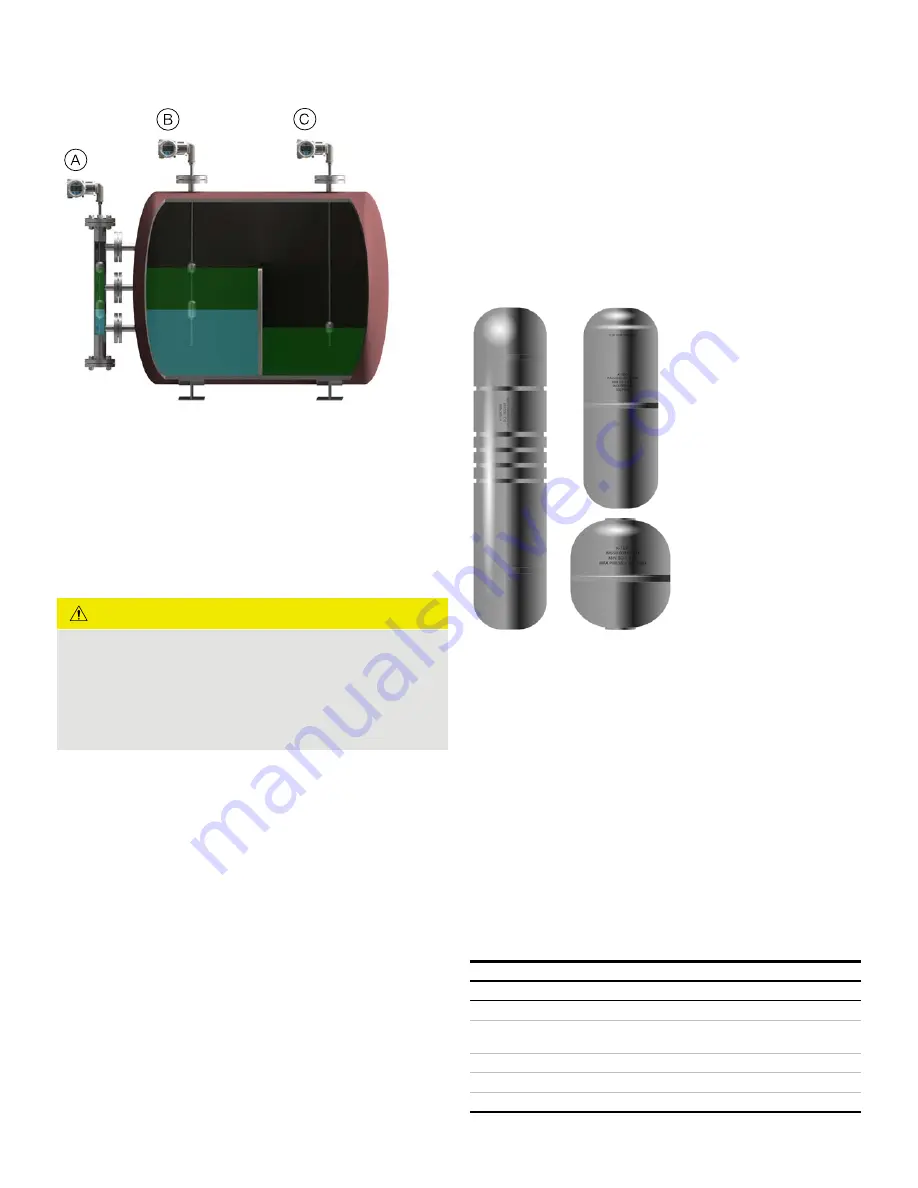

Figure 5 LMT100 Mounting

LMT100 Transmitters installations:

A

Installed in external chambers in a level and interface measurement

application

B

Installed directly into vessel, measuring level and interface level

C

Installed directly into vessel measuring level only

CAUTION

Do not run an external magnet on the outside of the sensor

and then take the magnet off This leaves residual magnetic

properties on the wire, causing a false echo if a magnet is

used, be sure to run the magnet from the sensor elbow to

the probe tip to ensure no residual magnetic field is

present

Compression fittings

When fitted with a compression fitting as the process

connection, the sensor tube is shipped with a set of TEFLON®

ferrules and a set of metal ferrules in a separate bag The

TEFLON® ferrules are only intended for use in applications with

operating pressures at or below 3 4 bar (50 psig) and process

temperatures at or below 204°C (400°F) For higher operating

pressures or temperatures or for permanent installation,

replace the TEFLON® ferrules with metal ferrules

Floats

The float is a key component of the LMT Series transmitter that

must be matched to the medium in respect of density, pressure

resistance and material durability Every LMT float is precisely

engineered to customer application, ensuring optimal accuracy

and performance Precisely spaced magnets create a 360°

magnetic field coverage, safeguarding level transmitter and

gauge performance, even the most challenging applications

Several materials of construction available including Titanium,

Monel®, Hastelloy® C, Stainless Steel, and Plastics Tefzel®,

Halar®, TEFLON® S protective coatings are also available

During installation, it may be necessary to remove the float and

spacer (if included) from the sensor tube For proper

operation, the float must be reinstalled using the proper

orientation Floats may be marked with “Top for SPM” or “Top

for LMT” These ends of the float must face the transmitter

head Other floats may be marked with an arrow indicating the

proper orientation If a float is etched with information but

does not indicate a proper orientation, it will be bidirectional

and can be installed in either direction

Figure 6 Floats

IMPORTANT NOTE

During installation, take care not to bend the probe tube, and

protect the float from shock and impact loads If the float is

removed during installation, it must be slid back onto the probe

tube afterwords for LMT100 with the “TOP” marking oriented

towards the sensor head end, to enable correct measurements

to be made For LMT200, the float must be installed in the

chamber in proper orientation

Sensor wells

Certain transmitter options have the sensor tube inserted into

a sensor well These options allow the sensor tube and housing

to be removed for service without breaking the seal on the

vessel These options include (consult model number) W1, W2,

W3, W4, W5, W6, C3, C4, W7, J4 and J5

Sensor Wells

Model

Sensor Type

Sensor Well

W1, W2,

½ in rigid

5/8 in. tube

W4, W5, W6,

C3, C4

5/8 in. rigid

¾ in pipe (typical)

W3,

½ in flexible stainless

5/8 in. tube

W7

5/8 in. flexible plastic

1 in. sectioned tube

J4, J5

½ in rigid

5/8 in. tube with TEFLON® jacket