LMT S E R I E S |

M AG N E TOS T R I C T I V E L E V EL T R A N SM I T T ER | O I/L M T 10 0/ 2 0 0 - EN R E V. B

15

• The electronic housing, in reference to the sensor tube, is

indicated by the model number:

– B1 or B2 – the housing is at the bottom of the sensor tube

– T1 or T2 – the housing is at the top of the sensor tube

• LMT Series transmitters are factory-calibrated to the

measuring length indicated by the ML on the device tag,

unless otherwise specified upon ordering

• Attach the LMT Series device to the side of the magnetic level

gauge (MLG) using the included worm gear clamps

• The gear clamps should slide between the scale and the level

gauge chamber It may be necessary to loosen the gear

clamps holding the scale to the MLG to install the transmitter

clamps Do not loosen all of the gear clamps all at once

• Align the factory zero mark with the “0” measurement mark

on the scale of the center of the bottom process connection

and tighten all gear clamps

CAUTION

Do not mount the LMT200 directly next to or touching the

steam tracing, if installed on chamber It is not

recommended to mount the LMT200 under an insulation

blanket If this is done, verify the sensor design can

withstand the full process temperature, and do not insulate

any closer than 6” from the sensor elbow connection

B

o

tt

o

m

M

oun

t

To

p

M

oun

t

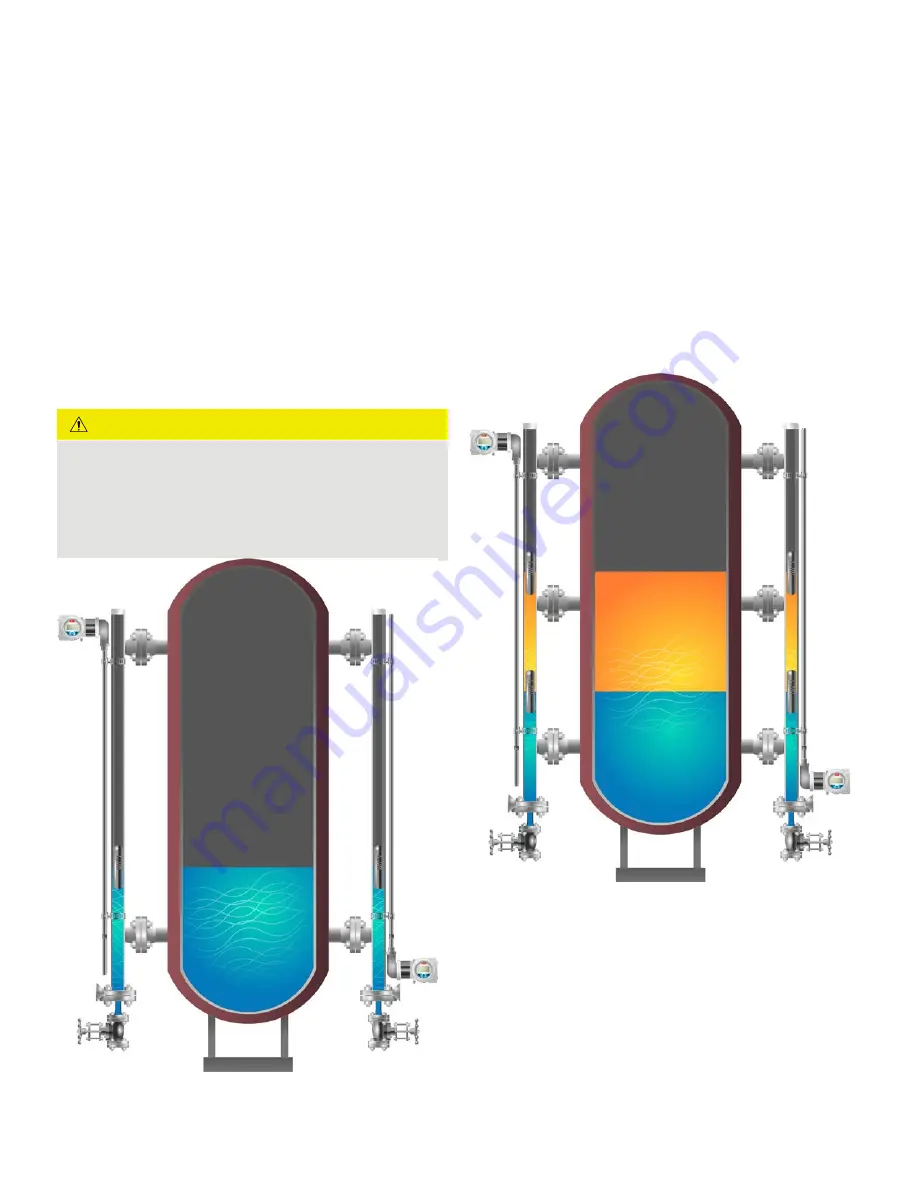

Figure 10 LMT200 Single Level Top / Bottom Mount

• Prior to installation, verify the model of the transmitter is

suitable for the intended application Information regarding

the model specifications may be found on the corresponding

LMT Series datasheets

• LMT Series transmitters mounted in high vibration areas

(such as near a compressor) should be mounted using

vibration isolators Vibration isolators take the place of the

standard mounting clamps

• The electronics housing should be maintained in the following

ambient conditions:

– Temperature range: –40°C to 85°C (–40°F to 185°F)

– Humidity: 0 to 95% R H non-condensing

• Proceed with the electrical installation (Refer to Section 6

“Transmitter Wiring”)

B

o

tt

o

m

M

oun

t

To

p

M

oun

t

Figure 11 LMT200 Dual Level Top / Bottom Mount

Insulation blankets or pads

• When an LMT Series transmitter is mounted on a level gauge

with an insulation pad or blanket, the insulation must pass

between the sensor tube and the body of the level gauge

Wrapping insulation around the sensor may cause damage to

its internal components

• A thick insulation blanket may require flattening to allow the

installation of the LMT Series transmitter

• Using the zero factory mark as a reference, mark and cut 19 mm x

19 mm (¾ inch x ¾ inch) holes in the insulation pad or blanket

that correspond to each mounting clip of the LMT Series

transmitter