CONFIGURATION OF FC610

CONFIGURATION

1TNC928250M0201

48

5

Configuration

5.1

Configuration of FC610

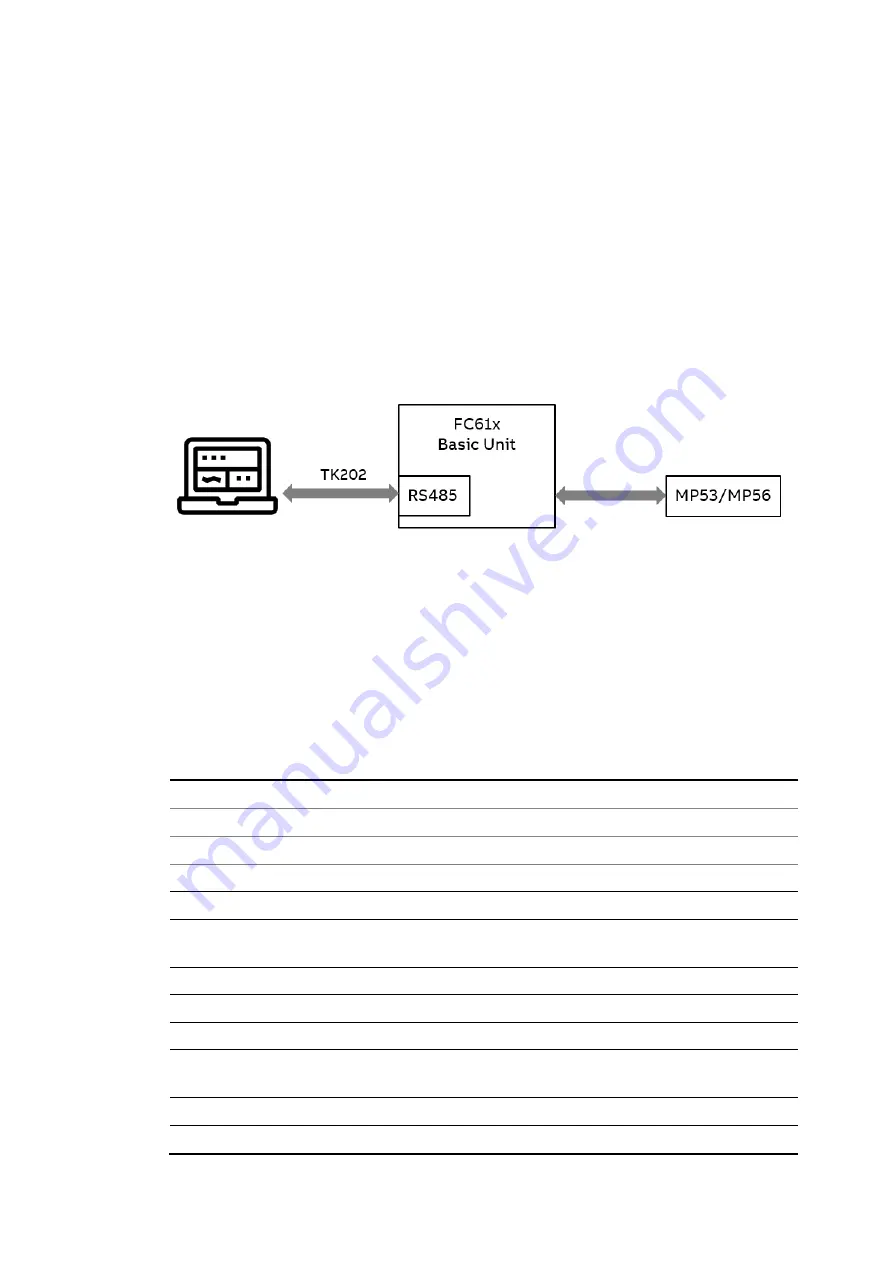

Parameters of FC610 are expected to be configured via HMI panel MP53 or MP56 which is de-

scribed in section 4.

In case of firmware updating or reading event curves, MConfig-G software must be used.

MConfig-G establish communication with FC610 via RS485 communication which is shown be-

low. A dedicated parameterization cable TK202 is required to connect FC610 and the configu-

ration computer with the MConfig-G software installed.

Figure 36: Configuration of FC610

It is also possible to configure FC610 via communication. Please refer to “1TNC928247 FC610

Modbus Protocol Implementation” for more information.

5.2

Factory default setting

For an easy startup of FC610, the following factory settings are preloaded in the device.

Parameters

Range

Factory setting

Feeder Information

Feeder ID

na

System supply voltage

110-50000 V

380 V

Frequency

50/60 Hz

50 Hz

Feeder type

Single phase/3- phase

/3-phase+N

3-phase+N

Feeder power rating

1.5 kW

Feeder nominal current

5 A

Feeder Control

Feedback Function

Current feedback/main switch

feedback*

Current Feedback

External CT Primary

1

External CT Secondary

1