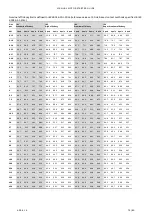

MANUAL MOTOR STARTER GUIDE

APRIL 19

79/80

Nominal efficiency limits defined in IEC 60034-30-1:2014 (reference values at 50 Hz, based on test methods specified in IEC

60034-2-1:2014).

Out-

put

IE1

Standard efficiency

IE2

High efficiency

IE3

Premium efficiency

IE4

Super Premium efficiency

kW

2 pole 4 pole 6 pole 8 pole 2 pole 4 pole 6 pole 8 pole 2 pole 4 pole 6 pole 8 pole 2 pole 4 pole 6 pole 8 pole

0.12

45.0

50.0

38.3

31.0

53.6

59.1

50.6

39.8

60.8

64.8

57.7

50.7

66.5

69.8

64.9

62.3

0.18

52.8

57.0

45.5

38.0

60.4

64.7

56.6

45.9

65.9

69.9

63.9

58.7

70.8

74.7

70.1

67.2

0.20

54.6

58.5

47.6

39.7

61.9

65.9

58.2

47.4

67.2

71.1

65.4

60.6

71.9

75.8

71.4

68.4

0.25

58.2

61.5

52.1

43.4

64.8

68.5

61.6

50.6

69.7

73.5

68.6

64.1

74.3

77.9

74.1

70.8

0.37

63.9

66.0

59.7

49.7

69.5

72.7

67.6

56.1

73.8

77.3

73.5

69.3

78.1

81.1

78.0

74.3

0.40

64.9

66.8

61.1

50.9

70.4

73.5

68.8

57.2

74.6

78.0

74.4

70.1

78.9

81.7

78.7

74.9

0.55

69.0

70.0

65.8

56.1

74.1

77.1

73.1

61.7

77.8

80.8

77.2

73.0

81.5

83.9

80.9

77.0

0.75

72.1

72.1

70.0

61.2

77.4

79.6

75.9

66.2

80.7

82.5

78.9

75.0

83.5

85.7

82.7

78.4

1.1

75.0

75.0

72.9

66.5

79.6

81.4

78.1

70.8

82.7

84.1

81.0

77.7

85.2

87.2

84.5

80.8

1.5

77.2

77.2

75.2

70.2

81.3

82.8

79.8

74.1

84.2

85.3

82.5

79.7

86.5

88.2

85.9

82.6

2.2

79.7

79.7

77.7

74.2

83.2

84.3

81.8

77.6

85.9

86.7

84.3

81.9

88.0

89.5

87.4

84.5

3

81.5

81.5

79.7

77.0

84.6

85.5

83.3

80.0

87.1

87.7

85.6

83.5

89.1

90.4

88.6

85.9

4

83.1

83.1

81.4

79.2

85.8

86.6

84.6

81.9

88.1

88.6

86.8

84.8

90.0

91.1

89.5

87.1

5.5

84.7

84.7

93.1

81.4

87.0

87.7

86.0

83.8

89.2

89.6

88.0

86.2

90.9

91.9

90.5

88.3

7.5

86.0

86.0

84.7

83.1

88.1

88.7

87.2

85.3

90.1

90.4

89.1

87.3

91.7

92.6

91.3

89.3

11

87.6

87.6

86.4

85.0

89.4

89.8

88.7

86.9

91.2

91.4

90.3

88.6

92.6

93.3

92.3

90.4

15

88.7

88.7

87.7

86.2

90.3

90.6

89.7

88.0

91.9

92.1

91.2

89.6

93.3

93.9

92.9

91.2

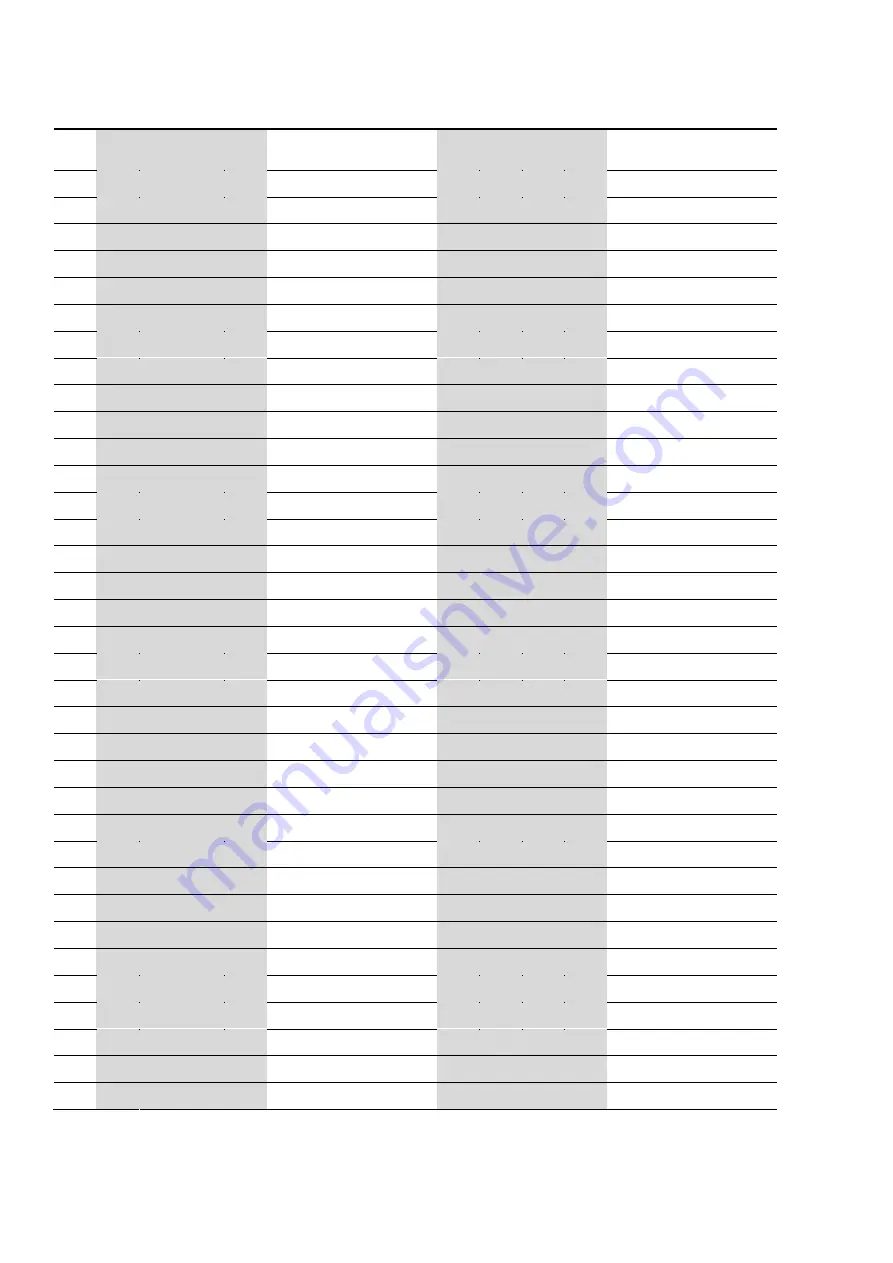

18.5

89.3

89.3

88.6

86.9

90.9

91.2

90.4

88.6

82.4

92.6

91.7

90.1

93.7

94.2

93.4

91.7

22

89.9

89.9

89.2

87.4

91.3

91.6

90.9

89.1

92.7

93.0

92.2

90.6

94.0

94.5

93.7

92.1

30

90.7

90.7

90.2

88.3

92.0

92.3

91.7

89.8

93.3

93.6

92.9

91.3

94.5

94.9

94.2

92.7

37

91.2

91.2

90.8

88.8

92.5

92.7

92.2

90.3

93.7

93.9

93.3

91.8

94.8

95.2

94.5

93.1

45

91.7

91.7

91.4

89.2

92.9

93.1

92.7

90.7

94.0

94.2

93.7

92.2

95.0

95.4

94.8

93.4

55

92.1

92.1

91.9

89.7

93.2

93.5

93.1

91.0

94.3

94.6

94.1

92.5

95.3

95.7

95.1

93.7

75

92.7

92.7

92.6

90.3

93.8

94.0

93.7

91.6

94.7

95.0

94.6

93.1

95.6

96.0

95.4

94.2

90

93.0

93.0

92.9

90.7

94.1

94.2

94.0

91.9

95.0

95.2

94.9

93.4

95.8

96.1

95.6

94.4

110

93.3

93.3

93.3

91.1

94.3

94.5

94.3

92.3

95.2

95.4

95.1

93.7

96.0

96.3

95.8

94.7

132

93.5

93.5

93.5

91.5

94.6

94.7

94.6

92.6

95.4

95.6

95.4

94.0

96.2

96.4

96.0

94.9

160

93.8

93.8

93.8

91.9

94.8

94.9

94.8

93.0

95.6

95.8

95.6

94.3

96.3

96.6

96.2

95.1

200

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.3

95.4

250

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.5

95.4

315

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.6

95.4

355

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.6

95.4

400

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.6

95.4

450

94.0

94.0

94.0

92.5

95.0

95.1

95.0

93.5

95.8

96.0

95.8

94.6

96.5

96.7

96.6

95.4