1

2TLC172007M0203_B.doc

Startup guide for Pluto Safety PLC, connected in a bus system

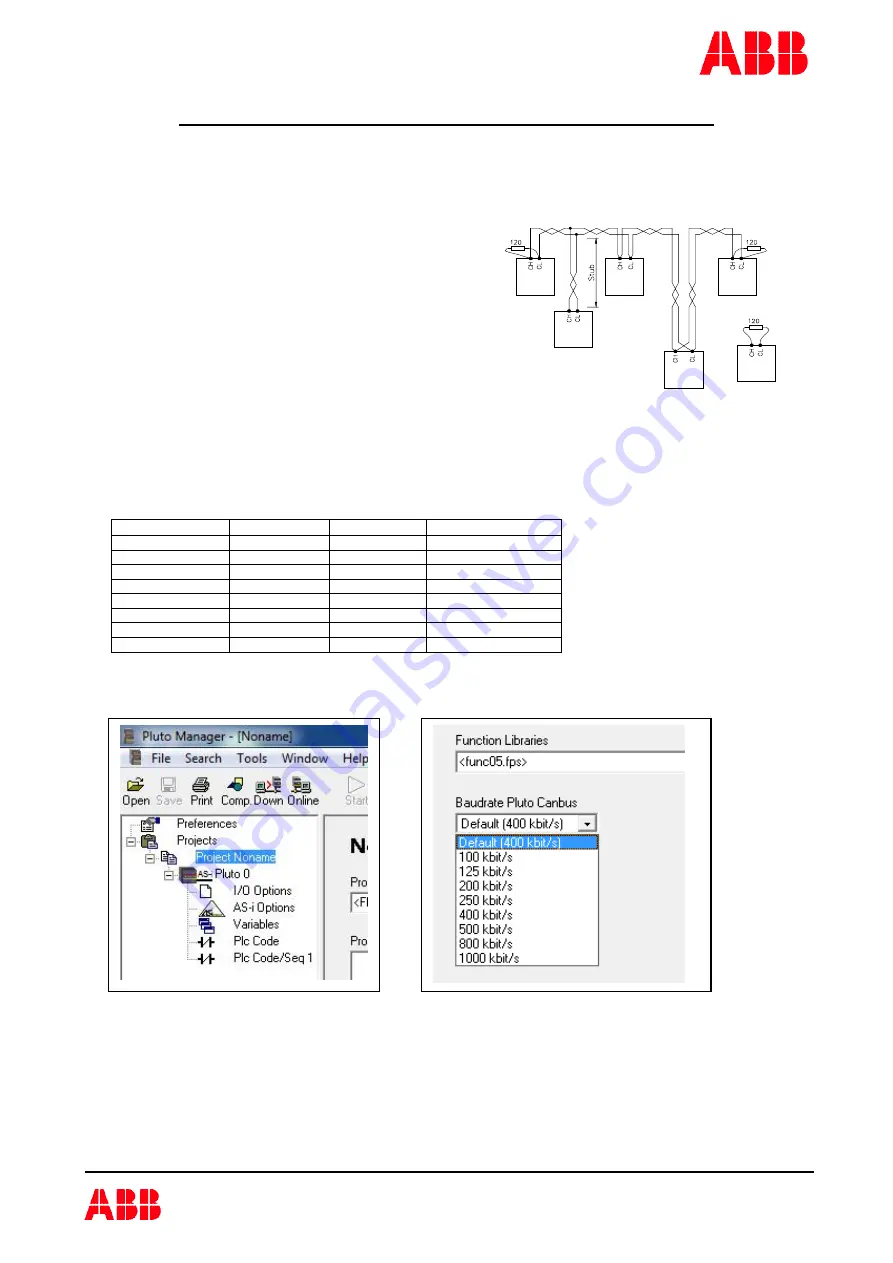

1. Check the bus cable

·

How many meters of bus cable have been

used?

·

Is the system connected with stub

cables?

·

How long is each stub?

·

What is the total length of stub cables?

·

Resistors for end termination must only

be connected in the beginning and the

end of the system.

·

When measuring the resistance between

CH and CL at one Pluto (all units shall be

dead) the resistance shall be somewhat

under 60

Ω

.

The following data are necessary to select the correct communication speed in the system. A lower speed

gives the possibility to communicate over a longer distance, but it results in that somewhat fewer Pluto’s can

be connected. A more detailed description can be found in the Pluto Hardware Manual, chapter Bus

communication.

Bus speed

Cable length

Stub length

Total stub length

100 kbit/s

600 m

25 m

120 m

125 kbit/s

500 m

20 m

100 m

200 kbit/s

300 m

13 m

70 m

250 kbit/s

250 m

10 m

50 m

400 kbit/s

150 m

6 m

30 m

500 kbit/s

100 m

5 m

25 m

800 kbit/s

60 m

3 m

15 m

1 Mbit/s

< 20 m

1 m

5 m

Communication speed for the project is set in the Pluto Manager. Open the window Project NoName, open

the pop-up menu under Baudrate Pluto Canbus and select the correct speed.

2. Read the IDFIX number

·

Must be performed before the program is downloaded to any of the units.

·

The programming cable must be connected to each Pluto when reading that particular Pluto’s IDFIX.

·

Read IDFIX numbers to all Pluto’s using the command “Copy online IDFIX to clipboard” under the

menu “Tools”. Paste the number to the corresponding Pluto.