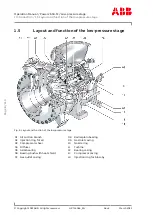

Operation Manual / Power2 650-M / Low-pressure stage

Table of contents

© Copyright 2022 ABB. All rights reserved.

HZTL4065_EN

Rev.E

March 2022

Power2 650-M / Low-pressure stage

Storage of new low-pressure and high-pressure stages..................................... 12