Operation Manual / Power2 845-M / Low-pressure stage

7 Periodic maintenance / 7.3 Cleaning turbine and nozzle ring during

operation

© Copyright 2022 ABB. All rights reserved.

HZTL4068_EN

Rev.E

March 2022

7.3.3

Wet cleaning of turbine blades and nozzle ring

Cleaning procedure

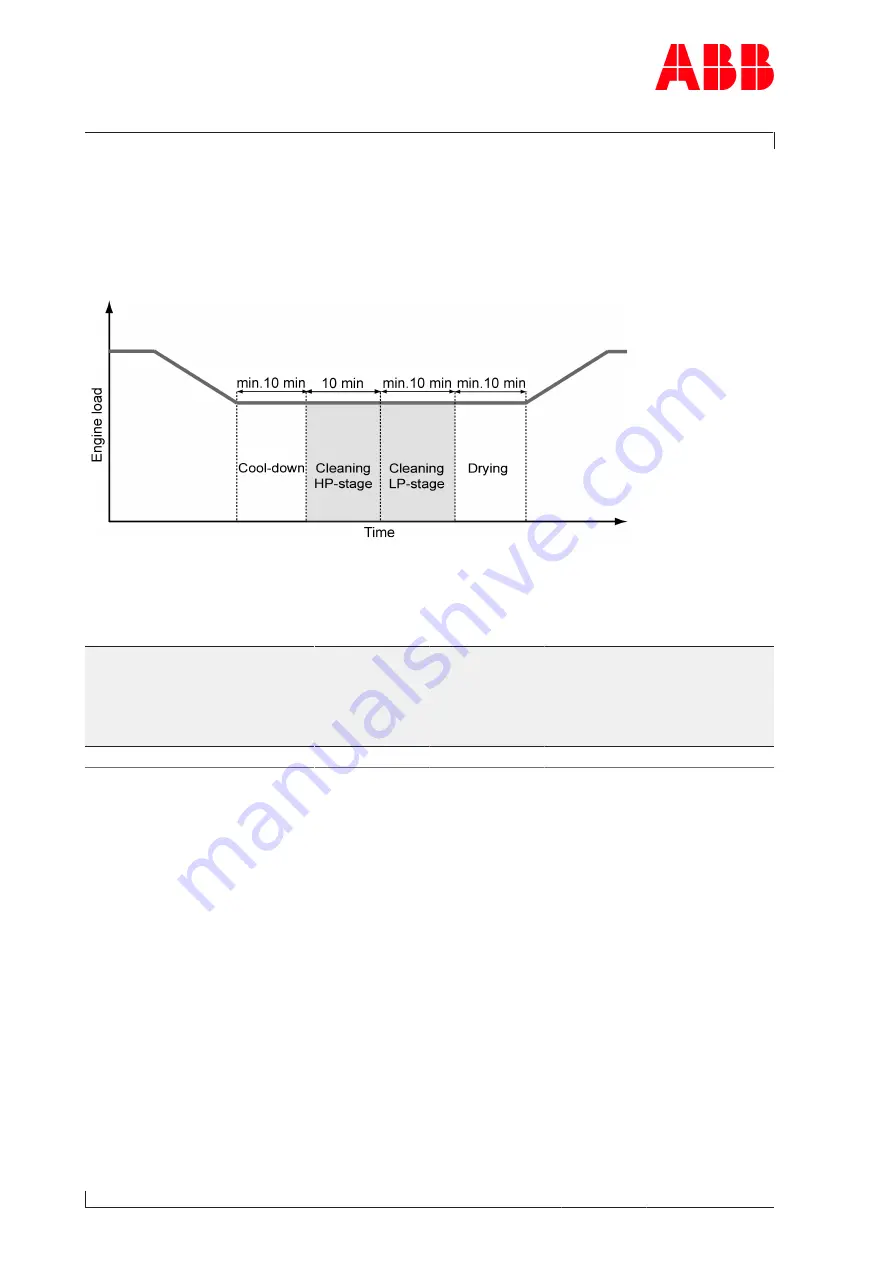

The individual phases of the turbine cleaning procedure are shown in the following illustra-

tion.

Fig. 19: Load/time chart

1. Cool down phase

u

Reduction of the engine load to the operating point for turbine cleaning and subsequent

maintenance of the holding time according to the specifications in the following table.

Power2

Gas pulse at

the inlet in the

HP stage

[N/m

2

]

Gas pulse at

the inlet in the

LP stage

[N/m

2

]

Engine load

[%]

Max. gas inlet

temperature

when starting

cleaning

[°C]

Holding time

at reduced

load

[min]

845

9500 ±2500

3200 ±800

25

430

≥

10

Table 18: Operating point for turbine cleaning

Algorithm for the gas pulse

For an optimum cleaning result, the gas pulse adopted when designing the cleaning process

should be set via the control system on the engine side. The algorithm for the gas pulse is

specified in the section

. If this is not possible, the spe-

cified engine load point is to be set as an approximation.

Thermomechanical stress

Due to the thermomechanical stress of the turbine casing, the gas inlet temperature should

not exceed the specified maximum temperature before starting cleaning. If this is the case,

the engine load is to be lowered until the permissible temperature is reached.

Page

56

/

119