Manual Power Quality Filter PQFS

Electrical design and installation 55

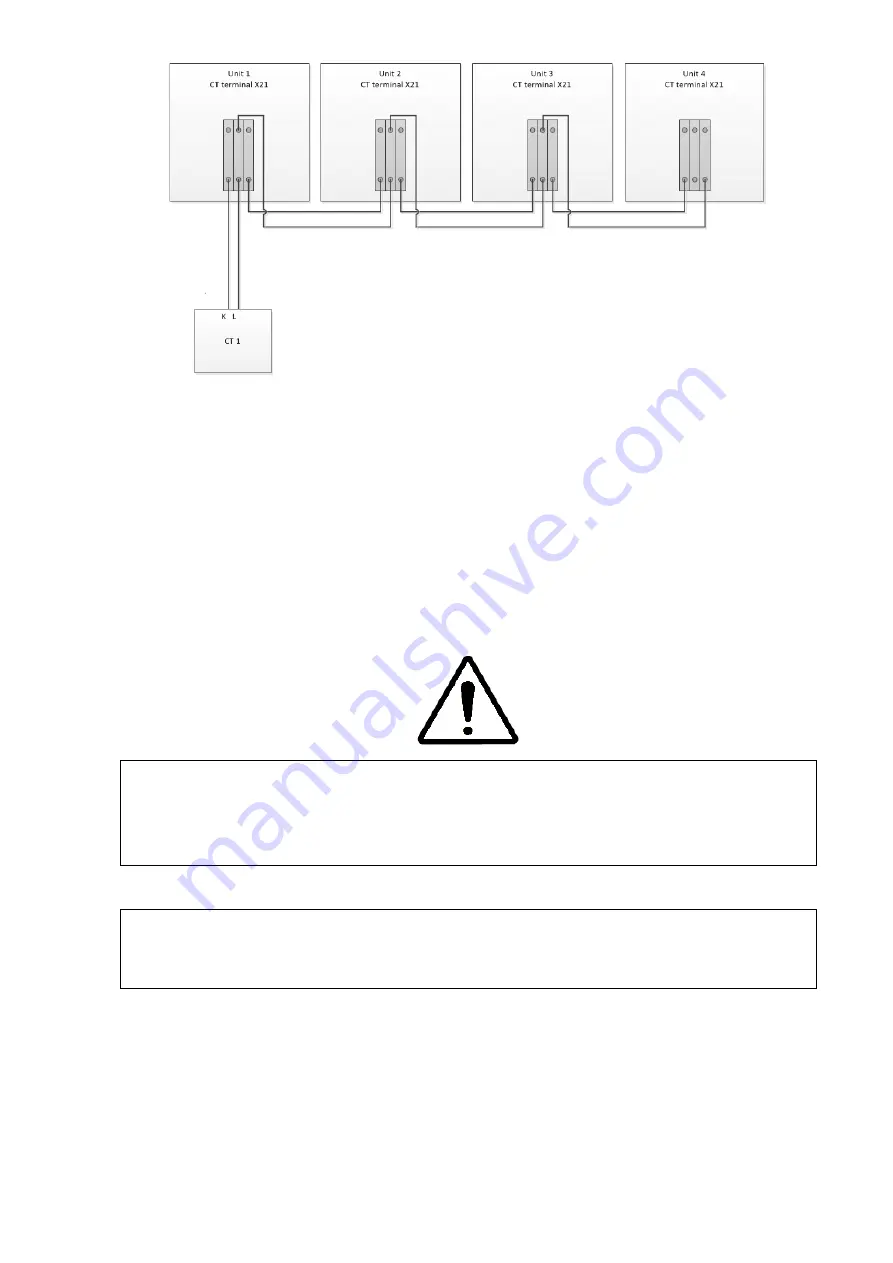

Figure 38: Principle of the CT interconnection circuit for multi-unit filters.

Note that the overall burden requirement for a complete filter system is 5 VA. To this

value has to be added the burden requirement of the interconnection cables to obtain

the total burden requirement of the CT’s to be used.

6.11.4

Connection of the power stage to the supply

As a final step in the interconnection process, the power stage of the new unit has to be

connected to the supply. The same connection approach as used for the other filter units

must be adopted. More information on how to connect a PQFS filter unit to the power

supply can be found in

Section 6.8

WARNING: Make sure that the phase rotation of the power cable connection is

clockwise at the filter terminals and that the L1, L2 and L3 terminal in each filter unit

is connected to the same phase for all units. Failure to do so may lead to the filter

being damaged upon startup.

WARNING: Once a new filter unit has been added to a filter system, this unit has to be

given a unique address (through DIP switch setting on its control board). In addition,

the filter unit has to be recommissioned.

If more than one unit is added, it is recommended to first finish the hardware

modifications and then set up the controller accordingly. More information on how to

change the filter controller unit settings can be found in

Section 7.9.2.2

Section 8.5

After making and verification of all the electrical connections:

−

Set a unique address on each filter unit control board

−

Close the auxiliary fuse box of the filter units