14 Hardware description

Manual Power Quality Filter PQFS

—

4

Hardware description

4.1

What this chapter contains

This chapter describes a typical PQFS-filter system and discusses its main components.

4.2

Typical PQFS filter panel layout

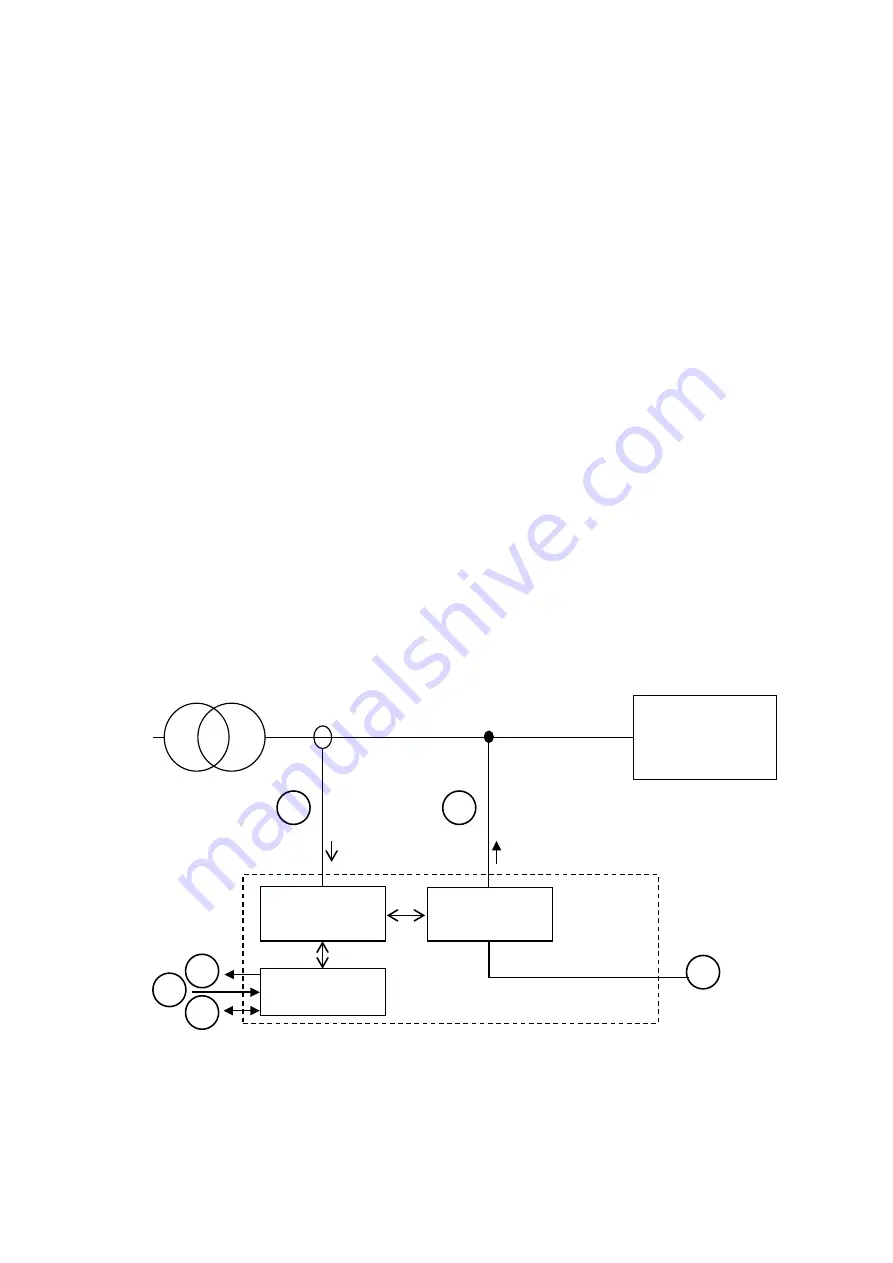

The PQFS active filter is basically composed of two parts (

−

A filter controller that determines the anti-harmonic current to be injected based

on the line current measurements and the user’s requirements. The line current

measurements are obtained from current transformers (CTs) provided by the

customer. The CTs must be connected upstream of the connection point of the

filter and the loads. The user enters his requirements by means of the PQF-

Manager user interface. This device also acts as the user’s connection point for

the alarm/warning contacts, the remote control functionality, the other digital

input functionality and the interface for external communication.

−

A current generator (power unit) that converts the control signals generated by

the filter controller into the filter compensation current. The current generator is

connected in parallel with the load(s). Up to eight power units may be connected

in parallel in one filter unit. The enclosure(s) containing the/a filter GUI controller

are referred to as master units. The other enclosures are referred to as the slave

units. In an active filter system more than one master unit can be present.

Compensation current

Current measurements

Non-linear load(s)

- Three-phase

- Single-phase

Supply

PQFS Filter panel

PQF main

controller

PQF current

generator 1

PQF Manager

1

2

3

5

4

6

Figure 8: PQFS schematic overview with user connections

The user connection description is given in