21

I N S TA L L AT I O N

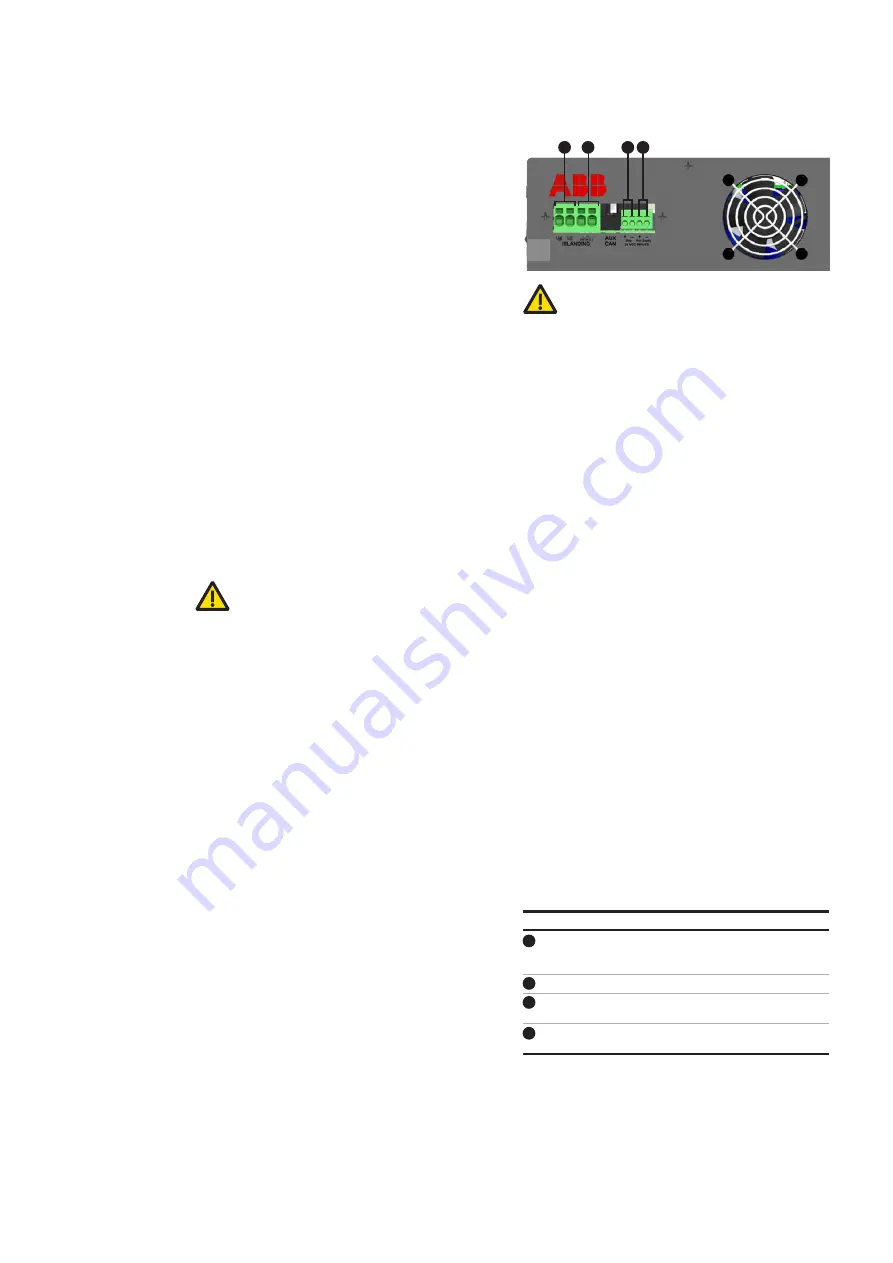

Components of the black start board

Measurement of the AC voltage across 1

pole of the islanding contactor/breaker

(not functional at present)

Islanding dry contact to control the main breaker

Input for the 24Vdc emergency

stop signal (mandatory)

Input for 24 Vdc power supply for extended

low voltage interruption (optional)

—

Figure 16: Black start board

—

Table 14: Connection terminals on the black start board

11

12

13

14

When powered, the module will automatically

check the phase rotation. If the power cables are

connected incorrectly, the module will not start,

the status button of the Wi-Fi user interface will

turn yellow (Section 4.1.3) and a message indicat-

ing wrong phase rotation will appear in Event

Logging (Section 4.1.7.3). Correct the phase rota-

tion before supplying power to the module to

avoid a potential malfunction or damage to the

equipment.

4.5.3 Battery

Connect the battery to the DC terminals on the

back of the PQstorI. Make sure that the positive

(+) terminal of the inverter is connected to the

positive (+) terminal of the battery (Figure 16). In-

verting the polarities will result in the error mes-

sage Global Battery Voltage Error (Section

4.1.7.4).

The PQstorI requires no external DC protection.

However, follow instructions provided by the bat-

tery supplier for any protection needed by the en-

ergy storage system and make sure that the in-

stallation meets local regulations for cable

protection.

Do not

ground the battery terminals.

4.5.4 Black start board

The inverter has a board (10 in Figure 2) with ter-

minals that interface with customer's system in

the matter of grid code compliance in some coun-

tries. This board is called as "blackstart board" as

it is intended to be used in the future for black

start/ islanding functions (not available yet).

The black start board includes supercaps to

enable the inverter to ride through low voltage

interruptions while still providing energy for the

control circuit without the use of an external

24Vdc supply (minimum 15sec holdup with fault

repetition less than 5 sec depending on the volt-

age depth). This function is comply with grid

code requirements (LVRT).

The black start board enables parallel connection

of a 24Vdc emergency stop signal (terminals 13 in

Figure 16 – MUST CONNECT) which interconnects

via the NS protection relay to comply with some

grid code requirements. Under normal operation

the inverter must receive a 24Vdc signal between

the terminals and, in case of an emergency stop,

the 24Vdc shall go to 0Vdc and the inverter has its

E-Stop function activated.

WARNING:

Even if the e-stop function is not re-

quired by local grid code, this e-stop connector

must be wired with 24 Vdc.

The blackstart board enables connection of an

external 24Vdc supply for extended low voltage

interruption beyond 15 seconds where it may be

required by local grid code requirements. Note

that with the external 24Vdc supply connected,

the supercaps of the black start PCBA are not

charged.

It also includes an islanding dry contact (termi-

nals 12 in Figure 16) for the main BESS breaker to

trip in an event of an active islanding detection by

the inverter. This function is also part of some

grid code requirements and might be connected

when applicable. The terminals 11 are not func-

tional and will be used for future functionalities

of the PQstorI inverter.

—

NOTE: The terminals 12 are suitable for cables

with cross-section from 0.5 mm² (20AWG) to

10mm² (8AWG). Only copper cables rated for 75°C

or above are allowed to be used. The terminals 13

and 14 are suitable for cables with cross-section

from 0.5 mm² (20AWG) to 2.5mm² (14AWG). Only

copper cables rated for 75°C or above are allowed

to be used.

11

12

13 14