Chapter 6

Human-Machine nterface (HM)

This chapter describes how the human-machine interface (keypad and display) works.

6:1 Overview

6:1.1 Application

The Human-Machine Interface is used for several purposes such as programming the softstarter, i.e setup of

inputs and outputs, protection functions, warning levels, fieldbus communication, etc. The HMI is also used for

monitoring, local control and receiving status information from the softstarter.

6:1.2 Design

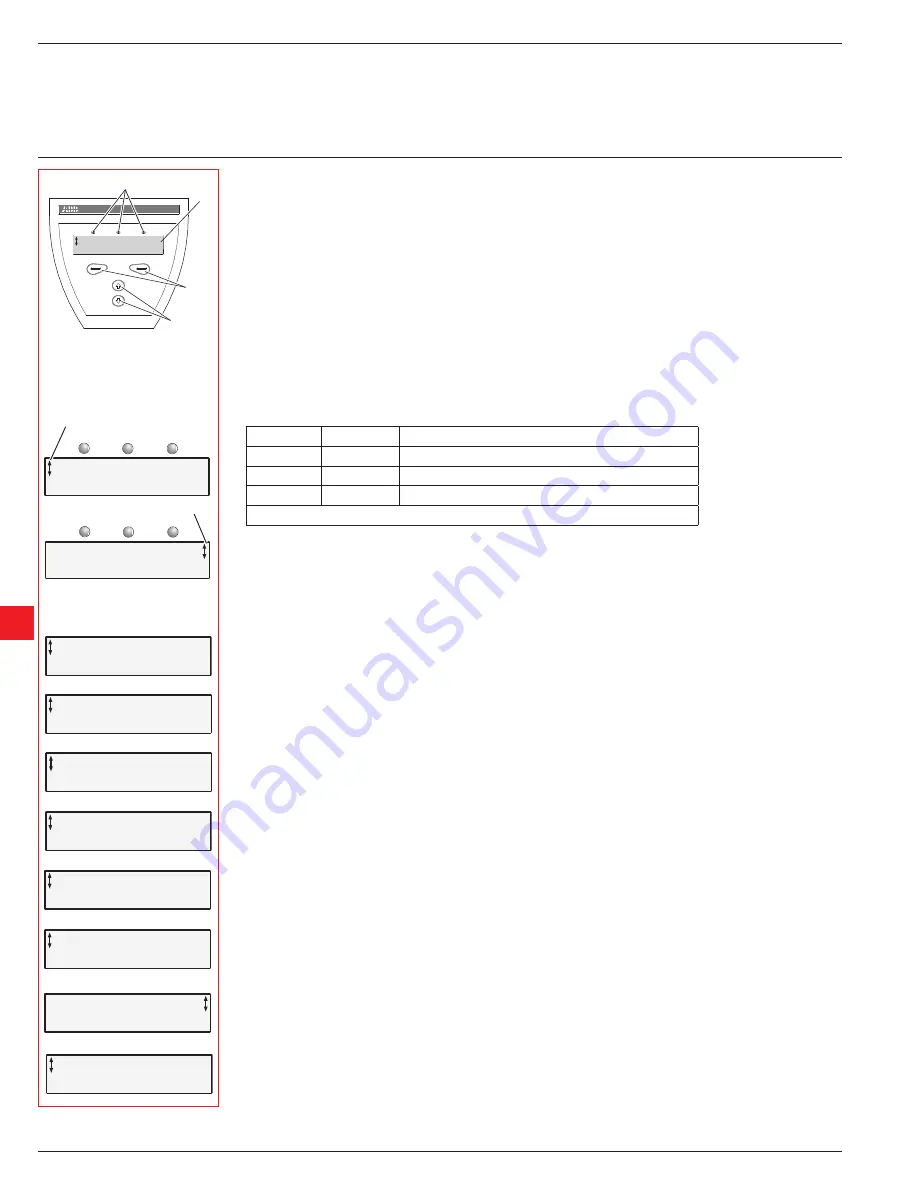

The HMI consists of:

• Status indication LED indicators

• LCD display

• Selection and Navigation keys

The LED indicators work as follows:

LED

Color

Description

Power on

Green

Control voltage connected

Fault

Red

Indicates faults

Protection

Yellow

Indicates protective function has activated

When a Fault or Protection LED is activated, the LCD displays the actual fault or protection.

The keypad is based on the same user concept as today’s mobile phones.

The LCD contains two rows with 20 characters each.

The top row presents various information depending on its state. The bottom row indicates which function is

currently selected.

A scrolling icon indicates what parameter or setting value is possible to change at the position.

The

Selection keys

normally have more than one function, such as selecting, changing and storing parameters.

See the text on the bottom row of the LCD.

The

Navigation keys

are used for navigating through the various menus to the desired setting.

When selecting from a list, the scrolling is done in a closed loop fashion.

The functionality of the keypad is illustrated by the following example:

Changing the rated motor current (Setting I

e

).

1. You will find the setting as well as a short explanation and the path to it in Chapter 10 “ Functions”.

Path in menu:

Menu/SETTINGS/Functional Settings/

Start/Stop /Setting Ie

2. The top level of the softstarter start menu looks as in Figure 3. Press the left selection key to enter the menu.

The display now appears as in Figure 4.

3. Press the left selection key to select

SETTINGS

. The display appears as in Figure 5.

4. Press the lower navigation key until the display appears as in Figure 6.

5. Press the left selection key to select

Functional settings

. Press the left selection key to select

Start/Stop

,

Figure 7.

6. Press the left selection key to

Change

the

Setting Ie

, Figure 8.

The display now appears as in Figure 9.

7. Use the navigation keys to set the rated current. If you want to quit, you select

Cancel

, using the right selec-

tion key. Otherwise, you store the new setting by selecting

Store

with the left selection key. The display should

now appear as in Figure 10.

8. Press the right selection key four times to return to top level.

Power on

Protection

Fault

1

2

3

4

Figure 1: Human-Machine Interface

1 Status indication LEDs

2 LCD display

3 Selection keys

4 Navigation keys

Figure 2: Menu examples

1 Scrolling icons

Power on

Protection

Fault

Power on

Protection

Fault

1

1

Setting Ie 100A

Change

Back

Setting Ie 100A

Store

Cancel

Setting Ie

99.5A

Change

Back

Figure 10: Setting Ie menu, changing setting

Setting Ie

100A

Store Cancel

Figure 9: Setting Ie menu, changing menu

Setting Ie

100A

Change Back

Figure 8: Setting Ie menu

Start/Stop

Select Back

Figure 7: Start/stop menu

Functional Settings

Select Back

Figure 6: Functional settings menu

Application Setting

Select Back

Figure 5: Application Setting menu

SETTINGS

Select Back

Figure 4: SETTINGS menu

U = 0% I = 0.0A

Menu

Figure 3: Top level

6.2

Low Voltage Products & Systems

1SXU 132 021 M0201

ABB nc. • 888-385-1221 • www.abb-control.com

6