130

Functions

| Installation and commissioning manual | 1SFC132081M0201

Parameter

Description

Setting range

Default value

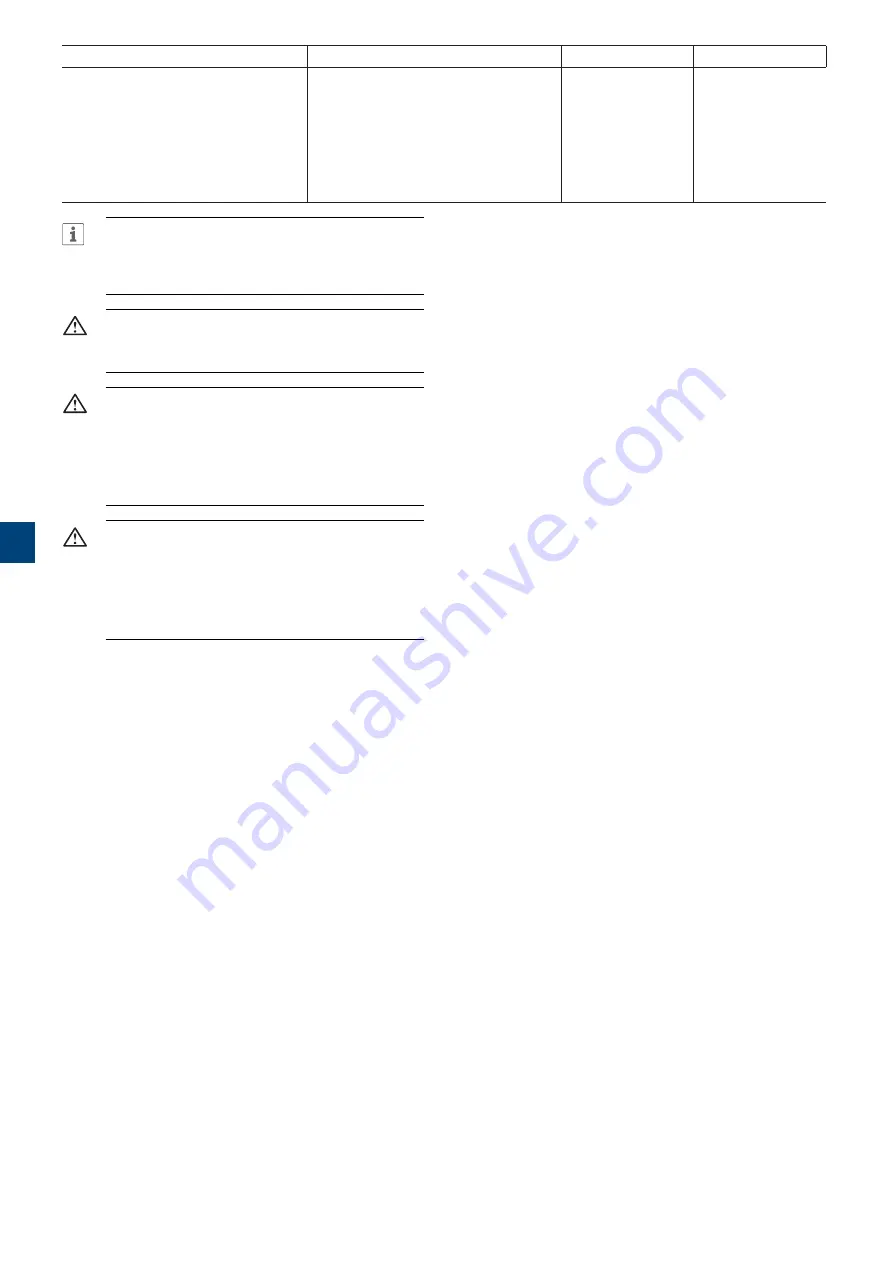

29.08 Pump clean stop mode

Sets the mode for stop used when pump

cleaning forward has finished: Stop ramp

followed by dynamic brake, or dynamic

brake only.

See chapter

7.2.2 Voltage stop ramp

and

7.3.2 Torque stop ramp

for stop ramp

parameters.

See chapter

7.11 Motor braking

for speed

threshold and delay time.

Voltage ramp and

brake, Torque ramp

and brake, Dynamic

brake

Torque ramp and

brake

INFORMATION

If many pump cleaning cycles are used and run

often, it is recommended to use a one size larger

Softstarter.

WARNING

Pump cleaning is only working when the

Softstarter is connected in-line

WARNING

Because the Pump clean reverse function warms

up the motor we recommend to use a PTC or

PT100 element for temperature monitoring. In

some conditions, the built-in EOL is not accurate

for this feature.

WARNING

Do not use pump cleaning on pumps which have

impeller or rotating shaft parts which can loosen

or jam during reverse rotation. If you do not obey

these instructions, this can cause equipment

damage.

7.22 Fast

take-off

The PSTX is equipped with a fast take-off functionality.

This means that by delaying some non-critical functions,

the time from the start signal is given until the voltage

is applied to the motor is reduced. The Fast take-off

enables motor voltage after approximate 600 ms from

received start signal, which is approximate 500 ms faster

than the regular operation of 1100 ms .

To reduce this time even more the parameter 28.02 Line

contactor close time can be set to 0, default is 250 ms,

see chapter 7.20.2. Then the time for received start to

voltage is applied will approximately be 350 ms and the

regular operation time will approximately be 850 ms.

The parameter 28.43 Motor connection is default Auto

this can be set to the actual motor connection then the

time for received start to voltage will be decreased by

approximately 100 ms.

Note:

Torque control- and dynamic brake performance

might be affected in a minor way in specific situations.

7

Summary of Contents for PSTX Series

Page 1: ...1SFC132081M0201 Softstarters Type PSTX30 PSTX1250 Installation and commissioning manual...

Page 4: ......

Page 6: ......

Page 10: ...10 Introduction Installation and commissioning manual 1SFC132081M0201 1...

Page 16: ...16 Quick start Installation and commissioning manual 1SFC132081M0201 2...

Page 29: ...1SFC132081M0201 Installation and commissioning manual Description 29 3...

Page 30: ...30 Description Installation and commissioning manual 1SFC132081M0201 3...

Page 36: ...36 Installation Installation and commissioning manual 1SFC132081M0201 4...

Page 50: ...50 Connection Installation and commissioning manual 1SFC132081M0201 6...

Page 72: ...72 Human machine interface HMI Installation and commissioning manual 1SFC132081M0201 6...

Page 143: ...1SFC132081M0201 Installation and commissioning manual Functions 143 7...

Page 144: ...144 Functions Installation and commissioning manual 1SFC132081M0201 7...

Page 148: ...148 Communication Installation and commissioning manual 1SFC132081M0201 8...

Page 156: ...156 Maintenance Installation and commissioning manual 1SFC132081M0201 9...

Page 168: ...168 Troubleshooting Installation and commissioning manual 1SFC132081M0201 10...

Page 176: ...176 Wiring and application diagrams Installation and commissioning manual 1SFC132081M0201 11...

Page 181: ...1SFC132081M0201 Installation and commissioning manual Third party licenses 181 12...

Page 183: ...1SFC132081M0201 Installation and commissioning manual Revision 183 13...

Page 187: ...1SFC132081M0201 Installation and commissioning manual Index 187 14...