7.16.12 Short circuit warning

A warning signal will be given if there is an internal short

circuit and the softstarter is running in limp mode.

Contact ABB sales office for service

.

Short circuit warning is configured with the following

parameters:

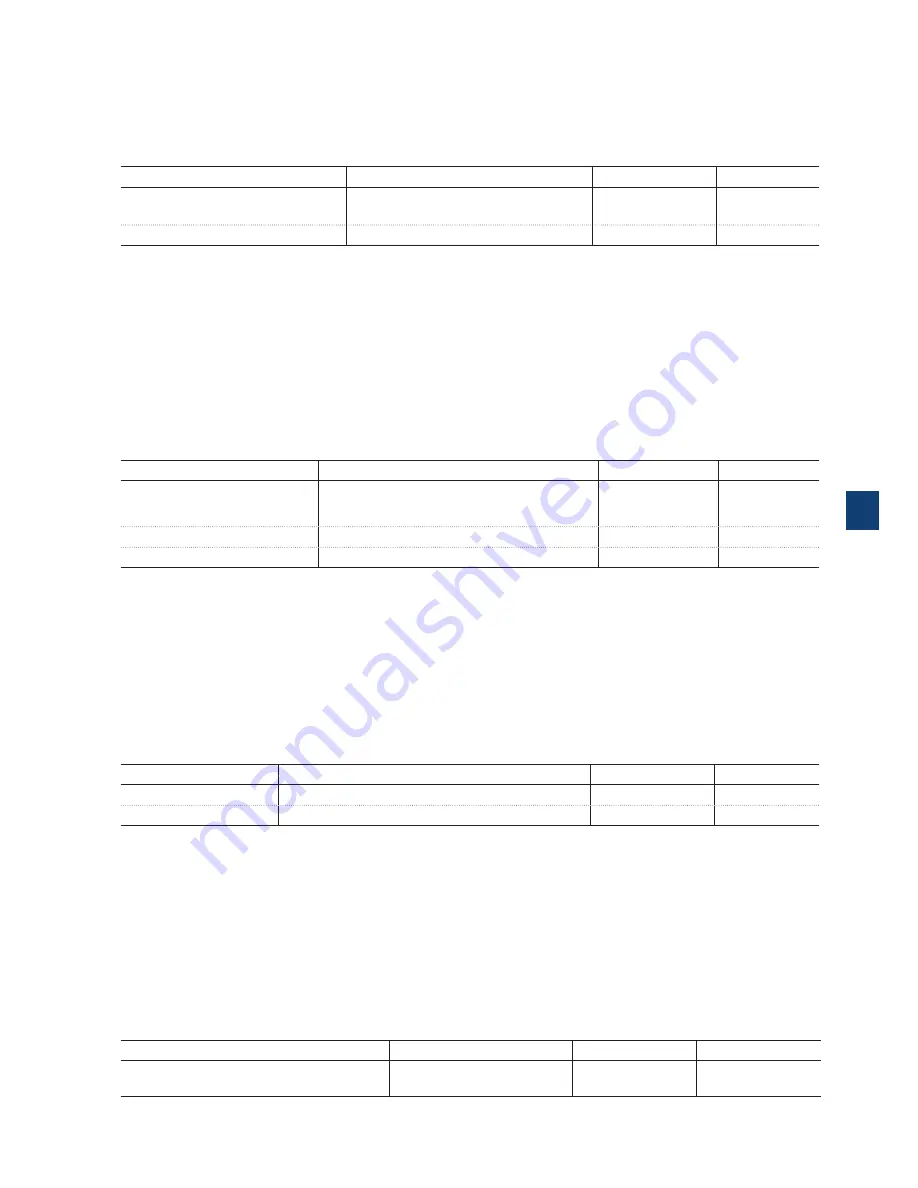

Parameter

Description

Setting range

Default value

23.07

Short circuit out

Specifies the Event groups this warning

belongs to.

Eventgroup 0 ... 6

4

23.08

Short circuit

Enables Short circuit warning.

Off, On

Off

7.16.13 Number of starts limits

A warning signal will be given if the number of starts

exceeds the configured trip level. The number of starts

counter can be reset to zero from the HMI.

The purpose of the warning is to allow for planed

maintenance of the equipment based on number of starts.

Number of starts limits warning is configured with the

following parameters:

Parameter

Description

Setting range

Default value

24.01

Number of starts lim

Sets the total number of starts that will activiate

a warning. This can for example be used when

identifying a need for service or maintanance.

1 ... 65535

65535

24.02

Number of starts out

Specifies the Event groups this warning belongs to.

Eventgroup 0 ... 6

4

24.03

Number of starts

Enables Number of starts limits warning level.

Off, On

Off

7.16.14 Fans fault warning

A warning signal will be given if the fans are not working

properly. There could be dust or other mechanical

blocking in the softstarter fans. Risk of overheating.

Contact ABB sales office for service.

Fans fault warning is configured with the following

parameters:

Parameter

Description

Setting range

Default value

25.04

Faulty fan out

Specifies the Event groups this warning belongs to.

Eventgroup 0 ... 6

4

25.05

Faulty fan

Enables Faulty fan warning.

Off, On

Off

7.16.15 Modbus configuration warning

A warning signal will be given if the built-in Modbus RTU

slave is enabled (parameter 12.02) but the Com3 function

is not set to Modbus RTU slave. To use modbus RTU, the

RTU slave must be enabled and the Com3 port must be

configured to be used for the Modbus RTU slave.

Modbus configuration warning is configured with the

following parameters:

Parameter

Description

Setting range

Default value

25.06

Modbus_RTU w/o auxport out

Specifies the Event groups

this warning belong to.

Eventgroup 0 ... 6

4

7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Summary of Contents for PSTX30

Page 4: ...Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 6: ...Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 10: ...1 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 16: ...2 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 26: ...3 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 32: ...4 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 44: ...5 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 64: ...6 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 124: ...7 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 128: ...8 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 131: ...9 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 132: ...9 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 142: ...10 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...

Page 145: ...11 Phone 800 894 0412 Fax 888 723 4773 Web www clrwtr com Email info clrwtr com...