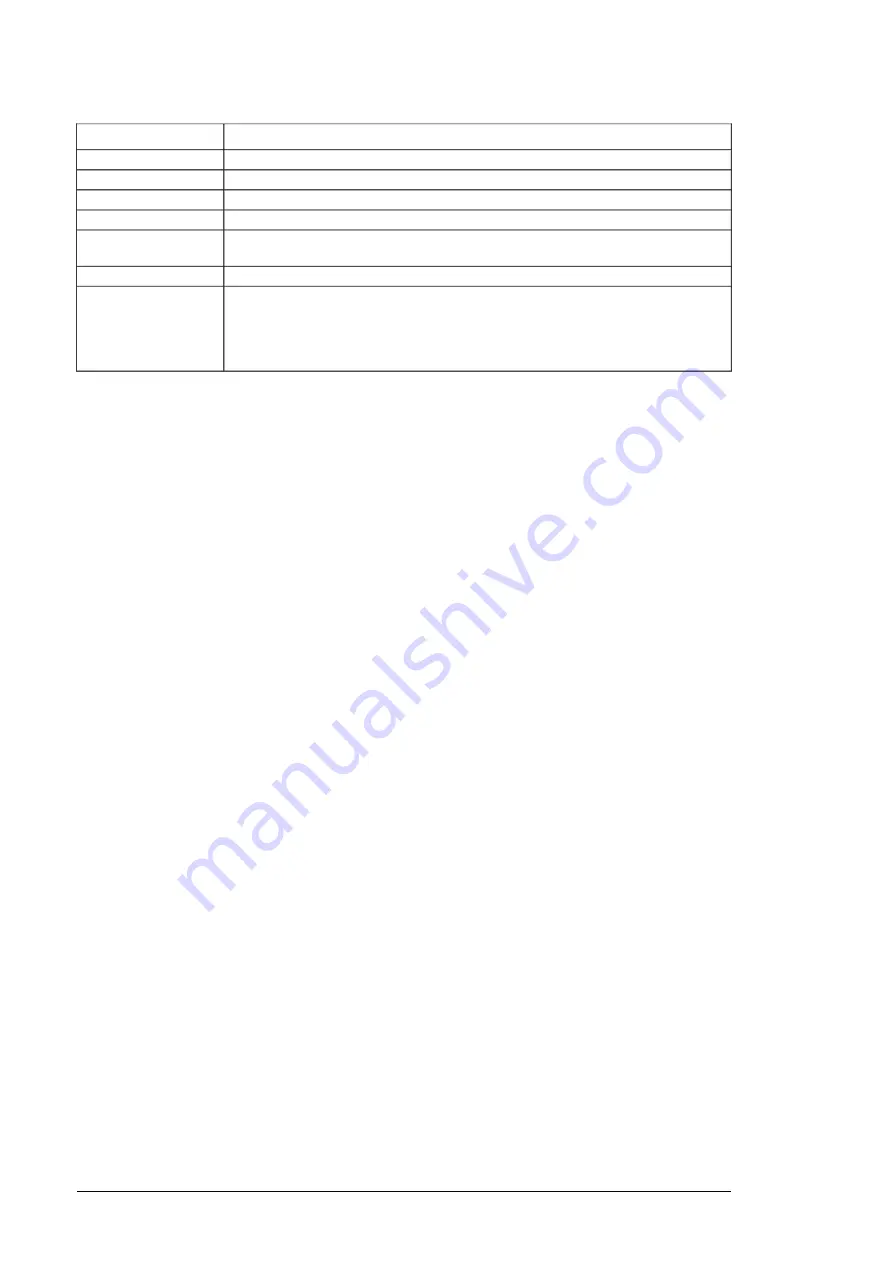

Description

Term

Performance level. Levels a...e correspond to SIL (EN ISO 13849-1)

PL

Prevention of unexpected start-up

POUS

Systematic capability (IEC 61508)

SC

Safety integrity level (1...3) (IEC 61508)

SIL

Maximum SIL (level 1...3) that can be claimed for a safety function or subsystem

(IEC/EN 62061)

SILCL

Safe torque off (IEC/EN 61800-5-2)

STO

Proof test interval. Defines the probabilistic failure rate (PFH or PFD

avg

) for the safety

function or subsystem. Performing a proof test at a maximum interval of T

1

is required

to keep the SIL capability valid. The same interval must be followed to keep the PL

capability (EN ISO 13849) valid. Note that any T

1

values given cannot be regarded

as a guarantee or warranty.

T

1

14 Introduction to the manual