GUID-9AFBA8CE-117E-427B-BFD0-0616D26149AA V3 EN

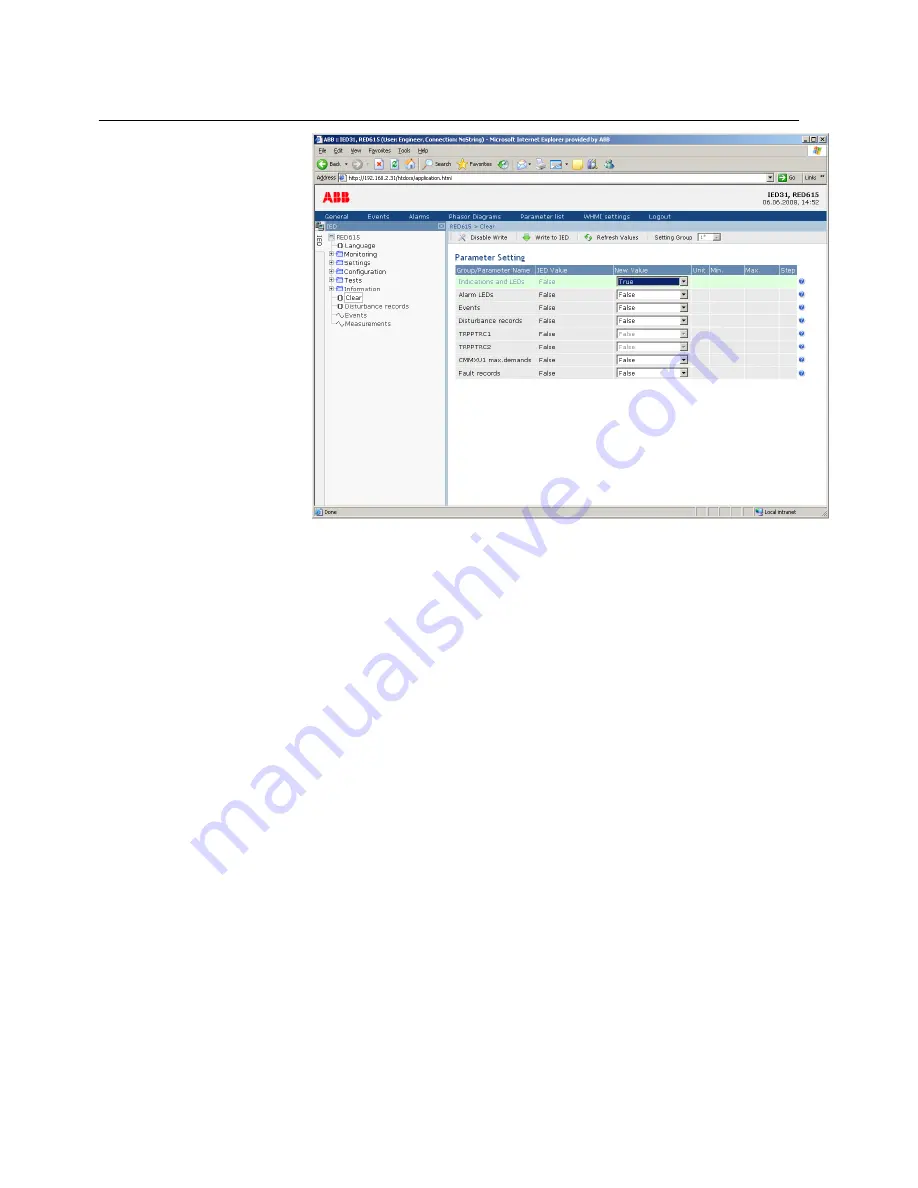

Figure 34:

Clearing indications and LEDs

4.2.9

Selecting alarm view

Alarm view shows the status of alarm LEDs. These are the same LEDs that are located

on the upper right side of the LHMI panel.

•

Click

Alarms

in the menu bar.

Section 4

1MRS756499 A

Using HMI locally or via web interface

52

RED615

Operation Manual