ABB REL 356 Current Differential Protection

2-6

Installation, Operation and Maintenance

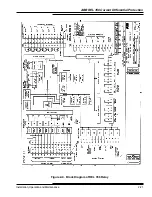

Digital Communication Interface DCI (56/64 kbps Digital Communication Option)

This module converts 5V logic level serial input and output data lines to/from CODEC module into one of the optional

interfaces:

• Fiber optic option, 820 nm, ST connector, multi-mode cable

• 56/64 kbps direct digital option, electrical standard RS422/RS485, mechanical standard RS530. The connec-

tor is a male DB-25 plug as required for Data Terminal Equipment (DTE). TXA is on pin 2, RXA pin 3, TXB pin

14 and RXB on pin 16. No clock synchronization input is required. Clock synchronization bit is taken from the

received dataframe.

• Fiber optic option, 1300 nm, ST connector, single-mode cable, short reach (12dB budget)

• Fiber optic option, 1300 nm, ST connector, single-mode cable, medium reach (22dB budget)

• Fiber optic option, 1300 nm, ST connector, single-mode cable, long reach (32dB budget)

The DCI assemblies connect to the rear of the REL356 relay via a 4 pin header.

Self-Checking Software

a. Digital Front-end A/D Converter Check

REL 356 continually monitors its ac input subsystems using multiple A/D converter calibration-check inputs. Failures of

the converter trigger alarms.

b. Program Memory Check Sum

Immediately upon power-up, the relay does a complete ROM (EPROM) checksum of program memory.

c. Power Up RAM Check

Immediately upon power-up, the relay does a complete RAM memory read/write tests.

d. Nonvolatile RAM Check

All settings and targets are stored in nonvolatile RAM in three identical arrays. These arrays are continuously checked

by the program. If all three array copies disagree, a nonvolatile RAM failure is detected.

Unique Remote Communication (WRELCOM) Program

Three optional types of remote interface can be ordered.

• RS232C for single point computer communication. (See IL 40-603, RCP Remote Communication Program.)

• INCOM for local network communication.

• Modbus PONI (See IL 40-616, PONI-M Modbus RS485 User’s Guide.)

A special PC software (WRELCOM RCP and OSCAR) program are available for obtaining or sending the setting informa-

tion to the REL 356. The REL 356 front panel shows two fault events (last and previous faults), but the remote commu-

nication, 16 fault events and 3 records of oscillographic data can be obtained and stored. Each record of the oscillo-

graphic data contains 8-cycle information (1-prefault and 7-post-fault), with 7 analog inputs and 24 digital data (at the

sampling rate of 12 per cycle).

Summary of Contents for REL 356

Page 23: ...ABB REL 356 Current Differential Protection 1 10 Product Overview and Specifications ...

Page 83: ...ABB REL 356 Current Differential Protection 3 36 Settings and Application ...

Page 127: ...ABB REL 356 Current Differential Protection 5 28 Testing ...

Page 186: ...LINE SECTIONALIZING USING A PLC AND ABB PROTECTIVE RELAY Page 49 of 53 ...

Page 187: ...LINE SECTIONALIZING USING A PLC AND ABB PROTECTIVE RELAY Page 50 of 53 ...

Page 188: ...LINE SECTIONALIZING USING A PLC AND ABB PROTECTIVE RELAY Page 51 of 53 ...

Page 189: ...LINE SECTIONALIZING USING A PLC AND ABB PROTECTIVE RELAY Page 52 of 53 ...