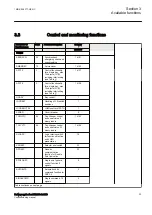

Table 4:

Number of function instances in APC10

Function name

Function description

Total number of instances

SCILO

Interlocking

10

BB_ES

3

A1A2_BS

2

A1A2_DC

3

ABC_BC

1

BH_CONN

1

BH_LINE_A

1

BH_LINE_B

1

DB_BUS_A

1

DB_BUS_B

1

DB_LINE

1

ABC_LINE

1

AB_TRAFO

1

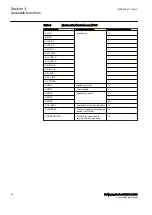

SCSWI

Switch controller

10

SXSWI

Circuit switch

9

QCRSV

Apparatus control

2

RESIN1

1

RESIN2

59

POS_EVAL

Evaluation of position indication

10

XLNPROXY

Proxy for signals from switching

device via GOOSE

12

GOOSEXLNRCV

GOOSE function block to

receive a switching device

12

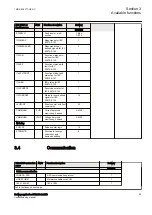

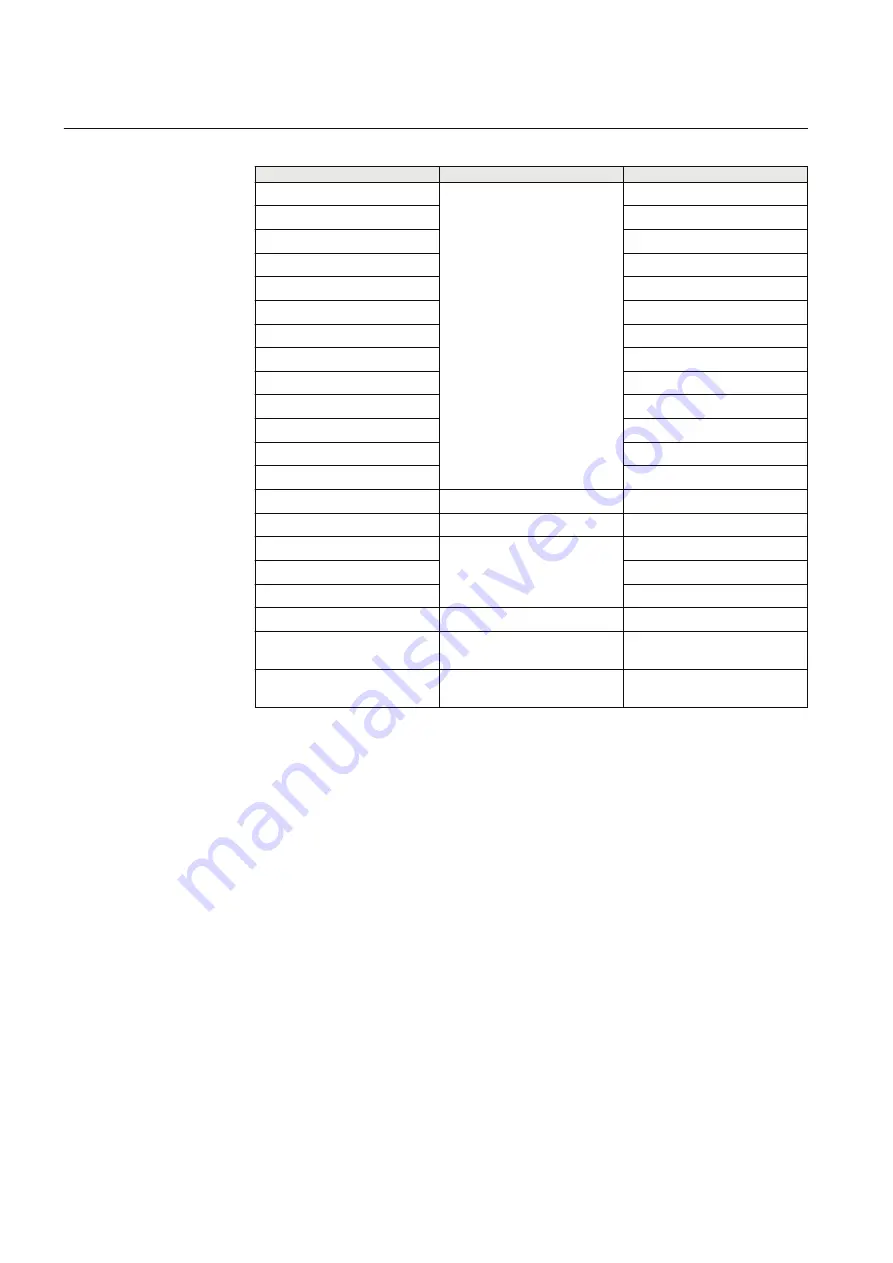

Section 3

1MRK 506 377-UEN C

Available functions

26

Railway application RER670 2.2 IEC

Commissioning manual

Summary of Contents for RELION RER670

Page 1: ...RELION 670 SERIES Railway application RER670 Version 2 2 IEC Commissioning manual...

Page 2: ......

Page 26: ...20...

Page 54: ...48...

Page 58: ...52...

Page 62: ...56...

Page 80: ...74...

Page 188: ...182...

Page 194: ...188...

Page 204: ...198...

Page 214: ...208...

Page 215: ...209...