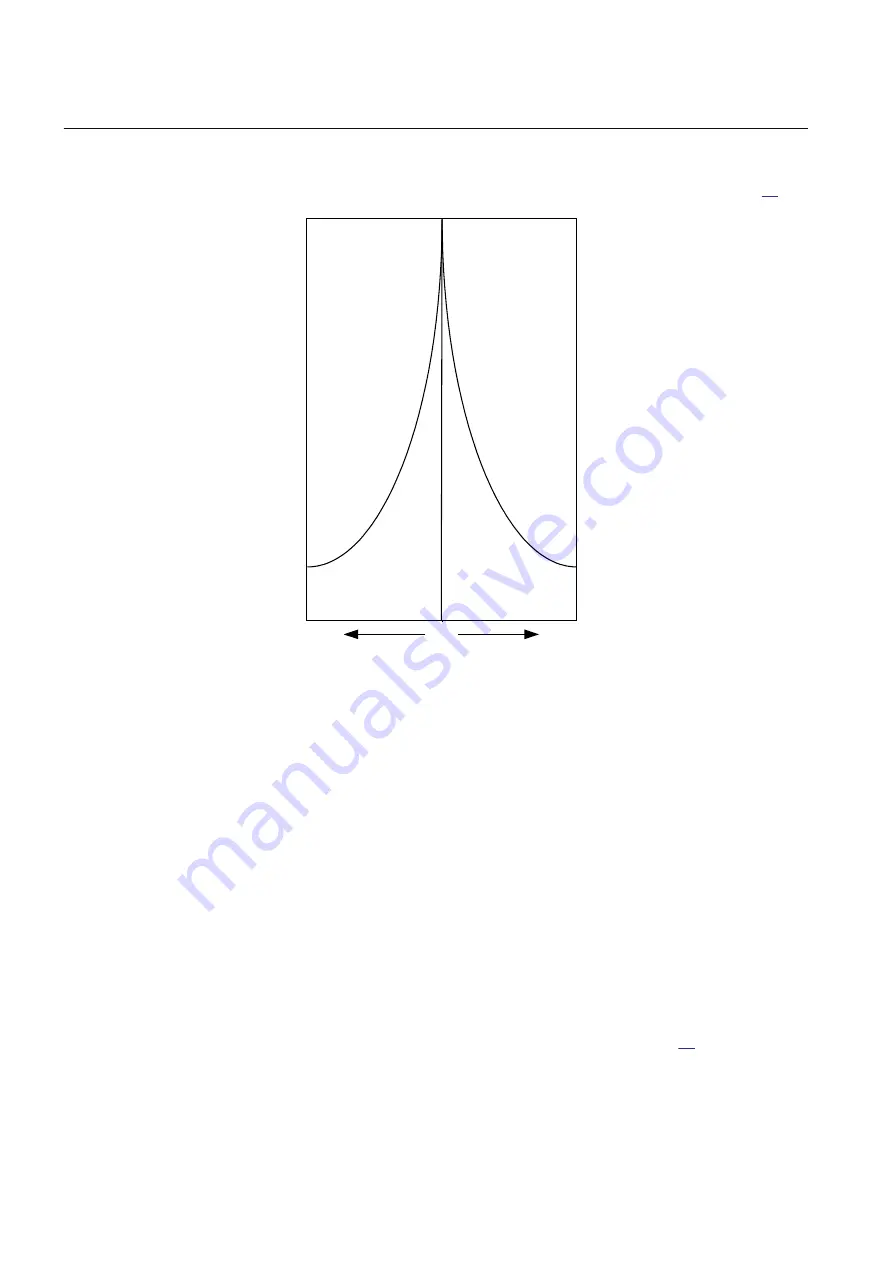

operating frequency is nearly equal to 1, mechanical stress on the blades is

approximately 300 times the nonresonant operating condition stress values. The

stress magnification factor is shown in the typical resonance curve in Figure

.

1.0

-

+

Frequency or Resonant Frequency

Ratio

S

tr

e

ss

M

ag

ni

fic

at

io

n

F

ac

to

r

IEC12000611-2-en.vsd

50

100

150

200

250

300

IEC12000611 V2 EN-US

Figure 71:

Typical stress magnification factor curve according ANSI/IEEE

C37.106-2003 Standard

Each turbine manufactured for different design of blades has various time

restriction limits for various frequency bands. The time limits depend on the

natural frequencies of the blades inside the turbine, corrosion and erosion of the

blade edges and additional loss of blade lifetime during the abnormal operating

conditions.

The frequency limitations and their time restrictions for different types of turbines

are similar in many aspects with steam turbine limitations. Certain differences in

design and applications may result in different protective requirements. Therefore,

for different type of turbine systems, different recommendations on the time

restriction limits are specified by the manufacturer.

However, the IEEE/ANSI C37.106-2003 standard "Guide for Abnormal Frequency

Protection for Power Generating Plants" provides some examples where the time

accumulated within each frequency range is as shown in Figure

Section 10

1MRK 511 407-UEN C

Frequency protection

186

Phasor measurement unit RES670 2.2 IEC

Application manual

Summary of Contents for Relion RES670

Page 1: ...RELION 670 SERIES Phasor measurement unit RES670 Version 2 2 IEC Application manual...

Page 2: ......

Page 46: ...40...

Page 52: ...46...

Page 92: ...86...

Page 112: ...106...

Page 178: ...172...

Page 216: ...210...

Page 232: ...226...

Page 286: ...280...

Page 328: ...322...

Page 340: ...334...

Page 380: ...374...

Page 381: ...375...