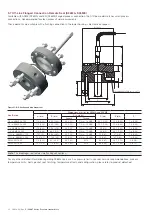

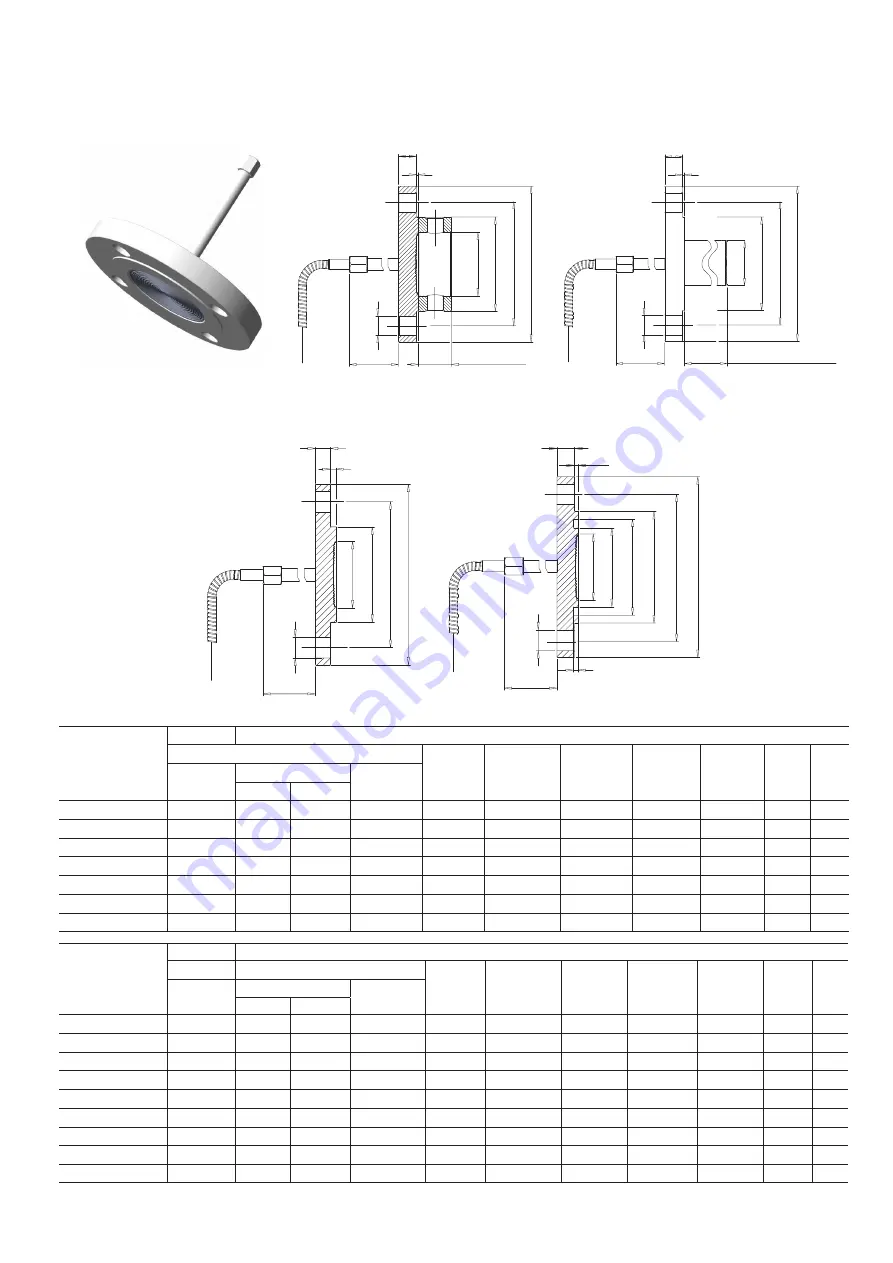

5.5 Fixed flange diaphragm seals – flush and extended (S26FA, S26FE)

These diaphragm seal are designed to connect to flanged pipe fitting, according to ASME or EN standards. For liquid level

measurement installations, the seal connects to a flanged tank nozzle, compliant to relevant standard. The sealing is provided by a

selectable gasket seat surface finish. The “fixed” mounting flange is integral with the seal.

Ø A

Ø B

Ø E

134 (5.3)

Ø D

Ø C

25 (0.98) for 1/4 NPT

33 (1.30) for 1/2 NPT

flushing threads

F

G

134 (5.3)

Ø B

Ø I

Ø H

F

L

3 (0.12)

Ø E

Ø C

Ø A

Ø D

Ø D

Ø B

Ø C

F

G

Ø E

134 (5.3)

Ø A

EN 1092-1 Form E

EN 1092-1 Form D

ASME and EN 1092-1 smooth and Form B1 (flushing ring as option, only for flush version)

Ø B

Ø E

134 (5.3)

Ø D

Ø C

F

G

Ø A

50, 100, 150 mm (1.97, 3.94, 5.91)

Insert lenght available

Figure 19: Fixed-flange diaphragm seal

Size/Rating

Dimensions mm (in) for S26FA

A (dia)

N°

of

holes

extended

diaphragm

flush diaphragm

flushing ring

internal dia

std.

low thick.

B (dia)

C (dia)

D (dia)

E (dia)

F (Note 1)

G

2 in. ASME CL 150

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

92 (3.62) 120.65 (4.75)

152.4 (6)

19.1 (0.79)

17.5 (0.6) 2 (0.08)

4

2 in. ASME CL 300

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

92 (3.62)

127 (5)

165.1 (6.5)

19.1 (0.79)

20.8 (0.8) 2 (0.08)

8

2 in. ASME CL 600

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

92 (3.62)

127 (5)

165.1 (6.5)

19.1 (0.79)

25.4 (1)

7 (0.27)

8

3 in. ASME CL 150

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

127 (5)

152.4 (6)

190.5 (7.5)

19.1 (0.79) 22.4 (0.88) 2 (0.08)

4

3 in. ASME CL 300

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

127 (5)

168.15 (6.62) 209.6 (8.25) 22.4 (0.86)

26.9 (1.1) 2 (0.08)

8

3 in. ASME CL 600

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

127 (5)

168.15 (6.62) 209.6 (8.25) 22.4 (0.86)

31.8 (1.3) 7 (0.27)

8

4 in. ASME CL 150

94 (3.7)

89 (3.5)

75 (2.95)

92 (3.62)

157.2 (6.2) 190.5 (7.5)

228.6 (9)

19.1 (0.79) 22.4 (0.88) 2 (0.08)

8

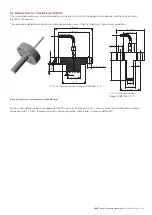

Size/Rating

Dimensions mm (in) for S26FE smooth and Form B1

A (dia)

N° of

holes

extended

diaphragm

flush diaphragm

flushing ring

internal dia

std.

low thick.

B (dia)

C (dia)

D (dia)

E (dia)

F (Note 2)

G

DN 50 EN PN 16

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

102 (4.02)

125 (4.92)

165 (6.5)

18 (0.71)

15 (0.58)

3 (0.12)

4

DN 50 EN PN 40

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

102 (4.02)

125 (4.92)

165 (6.5)

18 (0.71)

18 (0.67)

3 (0.12)

4

DN 50 EN PN 63

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

102 (4.02)

135 (5.31)

180 (7.08)

22 (0.86)

23 (0.9)

3 (0.12)

4

DN 50 EN PN 100

48 (1.9)

60 (2.36) 58 (2.28)

62 (2.44)

102 (4.02)

145 (5.71)

195 (7.67)

26 (1.02)

27 (1.06)

3 (0.12)

4

DN 80 EN PN 16

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

138 (5.43)

160 (6.3)

200 (7.87)

18 (0.71)

17 (0.67)

3 (0.12)

8

DN 80 EN PN 40

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

138 (5.43)

160 (6.3)

200 (7.87)

18 (0.71)

21 (0.83)

3 (0.12)

8

DN 80 EN PN 63

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

138 (5.43)

170 (6.7)

215 (8.46)

22 (0.86)

25 (0.98)

3 (0.12)

8

DN 80 EN PN 100

72 (2.83)

89 (3.5)

75 (2.95)

92 (3.62)

138 (5.43)

180 (7.08)

230 (9.05)

26 (1.02)

33 (1.3)

3 (0.12)

8

DN 100 EN PN 16

94 (3.7)

89 (3.5)

75 (2.95)

92 (3.62)

158 (6.22)

180 (7.08)

220 (8.66)

18 (0.71)

17 (0.67)

3 (0.12)

8

2600T Series Pressure transmitters |

OI/S266-EN Rev. B 19