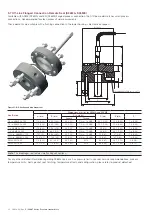

Seal with Chemical Tee flange

The union connection seal with a chemical tee flange is designed to connect to any process fitting which accepts a chemical tee

seal element (refer to Chemical Tee Seal for more information). The union seal connects to the chemical tee flange which serves as

an adapter to permit connection of the union seal to a chemical tee type fitting.

In addition to the O-ring required on the remote seal, this option requires a gasket to seal the chemical tee flange at its connection

to the process fitting. This gasket is included when the chemical tee flange option is specified. The gasket material is PTFE with

silica filler and the maximum operating temperature is 204°C (400°F). Note that the seal operating temperature limit can be lower

than this gasket temperature limit if the remote seal O-ring is silicone rubber with a 177°C (350°F) rating, or if the fill fluid has a

lower temperature limit (refer to the fill fluid parameter table in the Specification Sheet). The eight cap screws required to connect

the flange are supplied with the mating process fitting. The gasket and bolts have been specifically selected to meet the sealing

and pressure rating requirements of the chemical tee flange.

Substitution of user supplied bolts and gaskets is not recommended.

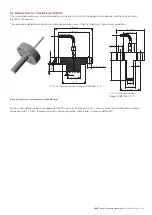

Connect the seal element using the following procedure:

1. Connect the chemical tee flange as follows:

Place the gasket on the flange sealing surface and insert flange into the process fitting.

Insert 8 cap screws and finger tighten each screw.

Following a diagonal sequence, tighten each cap screw to a torque of 12.4 Nm (110 inch-lbs).

2. Connect the union seal to the chemical tee flange as follows:

Remove protective covering from seal.

Lubricate the sealing O-ring with Silicone gasket grease.

Mount the O-ring on the end of the seal.

Insert the seal into the chemical tee flange and tighten the union connection nut to seal the O-ring against its mating surface.

8 Mounting Holes

Ø 8.7 (0.34) Equally spaced

127 (5)

25 (1)

13 (0.5)

Ø 127 (5)

Ø 96 (3.78)

Ø 42 (1.65)

Diaphragm Surface

Ø 111 (4.37)

Union Connection

57 (2.25)

Figure 30: Union connection remote seal with Chemical Tee flange

Note.

The pressure limit for a transmitter with this seal is determined by the chemical tee flange. Maximum working pressure for the flange is

2000 KPa (300 psi).

For any other detailed information regarding S26UN seals such as pressure limits, vacuum service recommendations, process

temperature limits, temperature effects and configuration, please refer to product datasheet.

2600T Series Pressure transmitters |

OI/S266-EN Rev. B 27