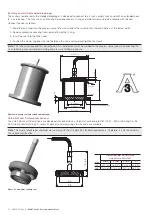

5.11 Food and Sanitary seal (S26SS)

Sanitary diaphragm seals have been specifically developed for food, sanitary, chemical and pharmaceutical applications,

complying with the stringent 3-A requirements.

Available with different process fittings (Triclamp, Cherry Burrell, Union Nut and Sanitary), this model highlights ABB’s commitment

to satisfy users needs approaching even the most demanding processes successfully.

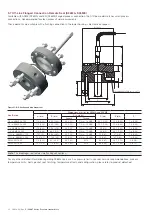

Cherry Burrell Aseptic

The sanitary aseptic remote seal is designed to connect to a 4in sanitary fitting: either an aseptic tank spud or a 4in Cherry Burrell

aseptic ferrule. The tank spud, gaskets and V-band clamp are available option with the seal element.

Note.

The tank spud or ferrule required for connection of this seal element must be welded to the process vessel prior to

connecting the element, following recommended welding and pressure testing procedure. Weld the Cherry Burrell ferrule to the

process vessel in accordance with manufacturers’ recommendations.

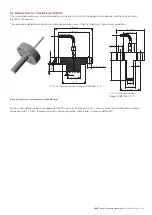

Connect the sanitary aseptic seal to the tank spud or ferrule as follows:

1. Remove protective covering from seal.

2. Install two O-rings on the periphery of the seal and an O-ring under each steam connection fitting.

3. Insert the seal into the tank spud or ferrule and place the steam connection cap against the back of the element.

4. Position the clamp ring as shown and tighten to seal the O-rings against the spud.

5. Connect the inlet and outlet steam lines to the 1/8. NPT steam connections in the cap. Steam temperature must not exceed

149°C (300°F); pressure must not exceed 358.5 KPa (52psi).

Ø 130 (5.11)

3 (0.11)

15 (0.59)

2.4 (0.09)

Ø 72.4 (2.85)

Ø 82.6 (3.25)

Ø 111.25 (4.37)

Ø 124 (4.88)

Figure 31: 4 in. Cherry Burrell Aseptic

28 OI/S26-EN Rev. B

| 2600T Series Pressure transmitters