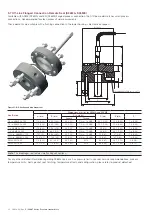

1 in. and 1-1/2 in. size to spud with 1 or 2 screw(s) fixing

Consider that this kind of pulp and paper sealing with gasket seal can withstand a maximum working pressure of:

— 30bar (435psi) in case of 1 screw fixing

— 50bar (725psi) in case of 2 screws fixing

The wetted parts are available in AISI 316L, Hastelloy C276

TM

and Diaflex (anti-abrasion diaphragm treatment).

While installing, please use the appropriate Viton™ gasket.

16 (0.63)

18 (0.71)

18 (0.71)

18 (0.71)

5/16-18 UNC

fixing hole for spud

113 (4.45)

29 (1.14)

145 (5.71)

45 (1.77)

26 (1.02)

40 (1.57)

16 (0.63)

18 (0.71)

18 (0.71)

18 (0.71)

5/16-18 UNC

fixing hole for spud

113 (4.45)

29 (1.14)

145 (5.71)

58 (2.28)

40 (1.57)

25.4 (1)

ø 26.7 (1.05)

ø 33.4

(1.31)

ø 8 (0.31)

25.4 (1)

ø 40.8 (1.61)

ø 48.2

(1.90)

ø 8 (0.31)

Figure 44: S26KN with spuds and fixing screws

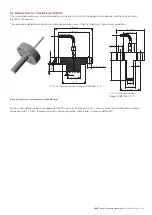

1 in. G with ball valve connection

This special connection allows easy instrument mounting on

ball valves which are easy to install and repair. They offer user

the opportunity of avoiding complete plant shutdown. This

process connection can withstand a maximum working

pressure of 40bar (580psi). The wetted parts are available only

in Hastelloy C276

TM

.

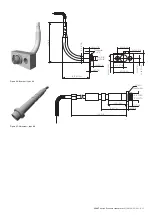

1-1/2 in. sealing connection to threaded spud (M44 x1.5)

Consider that this particular process connection can withstand

a maximum working pressure of 50bar (725psi).

While installing, please use the appropriate PTFE gasket.

The wetted parts are available in AISI 316L, Hastelloy C276

TM

and Diaflex (anti-abrasion diaphragm treatment).

16 (0.63)

18 (0.71)

18 (0.71)

18 (0.71)

70 (2.76)

M44 x 1.25

35 (1.38)

113 (4.45)

29 (1.14)

145 (5.71)

46 (1.81)

width across flats of hexagon

16 (0.63)

18 (0.71)

18 (0.71)

18 (0.71)

127 (5)

20 (0.79)

25 (0.98)

37 (1.46)

30 (1.18)

G 1 in.

113 (4.45)

29 (1.14)

145 (5.71)

Figure 45: S26KN with ball valve connection

Figure 46: S26KN with M44 x 1.5 trheaded spud connection

36 OI/S26-EN Rev. B

| 2600T Series Pressure transmitters