4 Installation

4.1 General

The transmitters with remote seals are suitable for use on the

following pressure and differential pressure measurement

applications:

— FLOW MEASUREMENT

— LIQUID LEVEL MEASUREMENT

— INTERFACE LEVEL MEASUREMENT

— DENSITY MEASUREMENT

— GAUGE PRESSURE MEASUREMENT

— ABSOLUTE PRESSURE MEASUREMENT

Each application has certain unique requirements which

influence the selection of the transmitter and seal locations. In

general the flow and gauge pressure applications allow the

greatest flexibility in selection of a location. Liquid level

applications impose restrictions on the relative elevations of the

transmitter and seals when the tank operates under vacuum

and absolute pressure applications impose similar restrictions

when the lower range value is less than atmospheric pressure

(nominally 14.7 psia). Transmitters with remote seals measure

pressure from two sources: the applied process pressure or

differential pressure, and the head pressure developed by the

weight of the liquid column in the seal system. The head

pressures are a function of transmitter and seal locations as

follows:

—

Two

Seals

On a DP transmitter with a seal on both the high and low

sides, the transmitter measures the head pressure

resulting from any difference in elevation between the

seals and the output change is directly proportional to the

elevation difference. The head pressure has no effect on

transmitter output when both seals are at the same

elevation. Changing the elevation of the seals relative to

the transmitter has no effect as long as the elevation of

one seal relative to the other is not changed.

—

One

Seal

On a transmitter with one seal, the head pressure from the

seal system is measured directly. Any change in the

elevation of the seal causes a change in the measured

head pressure and the transmitter output changes in

direct proportion to the elevation change.

Note.

When handling and/or installing the transmitter with

remote seal(s), please consider that the minimum bending

radius of the capillary system is 10 cm (3.9 in).

For most flow, gauge pressure, and absolute pressure

installations the effect of head pressure is relatively minor and

can be canceled out by adjusting zero with the transmitter and

seals in their installation position while a known process

pressure is applied. For liquid level installations, head pressures

have a more significant impact on calibration requirements

because the nature of the installation requires a substantial

difference in elevation between the high and low side seals.

See the Liquid Level Measurement Section for more

information.

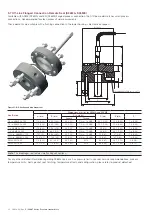

4.2 Flow measurement

Differential pressure transmitters with two remote seals can be

used for both horizontal and vertical flow measurement

installations by mean of a Wedge Flow Element. In both

horizontal and vertical installations, the transmitter can be

placed in any convenient location either above or below the

elevation of the seal elements. The high side seal element must

be located on the upstream side of the flow restriction. To

ensure accurate measurements on liquid flow applications, the

flow restriction must be located in a section of the pipe line

which remains full under all flow conditions.

—

Horizontal

Installation

In a horizontal installation both seal elements are at the

same elevation and head pressures resulting from the

filling liquid are equal on the high and low side of the

transmitter. Thus, the transmitter calibration can be zero

based for this installation. If the process contains

suspended solids, the seal elements should be located at

the top of the pipe to avoid collection of solid material on

the seal diaphragm surfaces.

—

Vertical

installation

In a vertical installation, the elevation difference between

the two seals applies a differential pressure when there is

no flow. When the pipe is full at no flow the initial

differential is a function of the distance between the seals

and the difference in density between the process liquid

and the fill liquid.

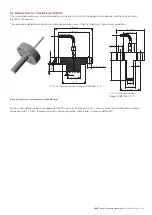

Figure 2: Primary element (Wedge) - vertical and horizontal installations for

flow measurements

2600T Series Pressure transmitters |

OI/S266-EN Rev. B 9