16

INSTRUCTION HANDBOOK

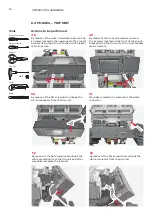

Tools

Flat screwdriver

Scissors

Cutter

Torx key

6.4 PHASE 4 – TRIP UNIT

48

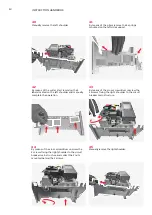

By means of the cross screwdriver unscrew the

2 screws located in the upper part of the circuit

breaker fixing the trip unt to the circuit breaker

main structure.

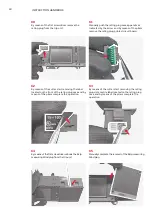

50

By means of the flat screwdriver unhook the

white connector from the trip unit.

52

By means of the flat screwdriver unhook the

cable protection from the trip unit and after

manually complete the removal.

49

By means of the cross screwdriver unscrew

the 2 screws located on the front of the circuit

breaker fixing the trip unt to the circuit breaker

main structure.

51

Manually complete the removal of the white

connector.

53

By means of the flat screw driver unhook the

white connector from the trip unit.

Actions to be performed

No. 8

Cross screwdriver

Pliers