ABB | SACE Emax 2

18 | © 2019 ABB | 1SDH001000R0002 - ECN000109166 - Rev. D

Management operations | 3 - Description

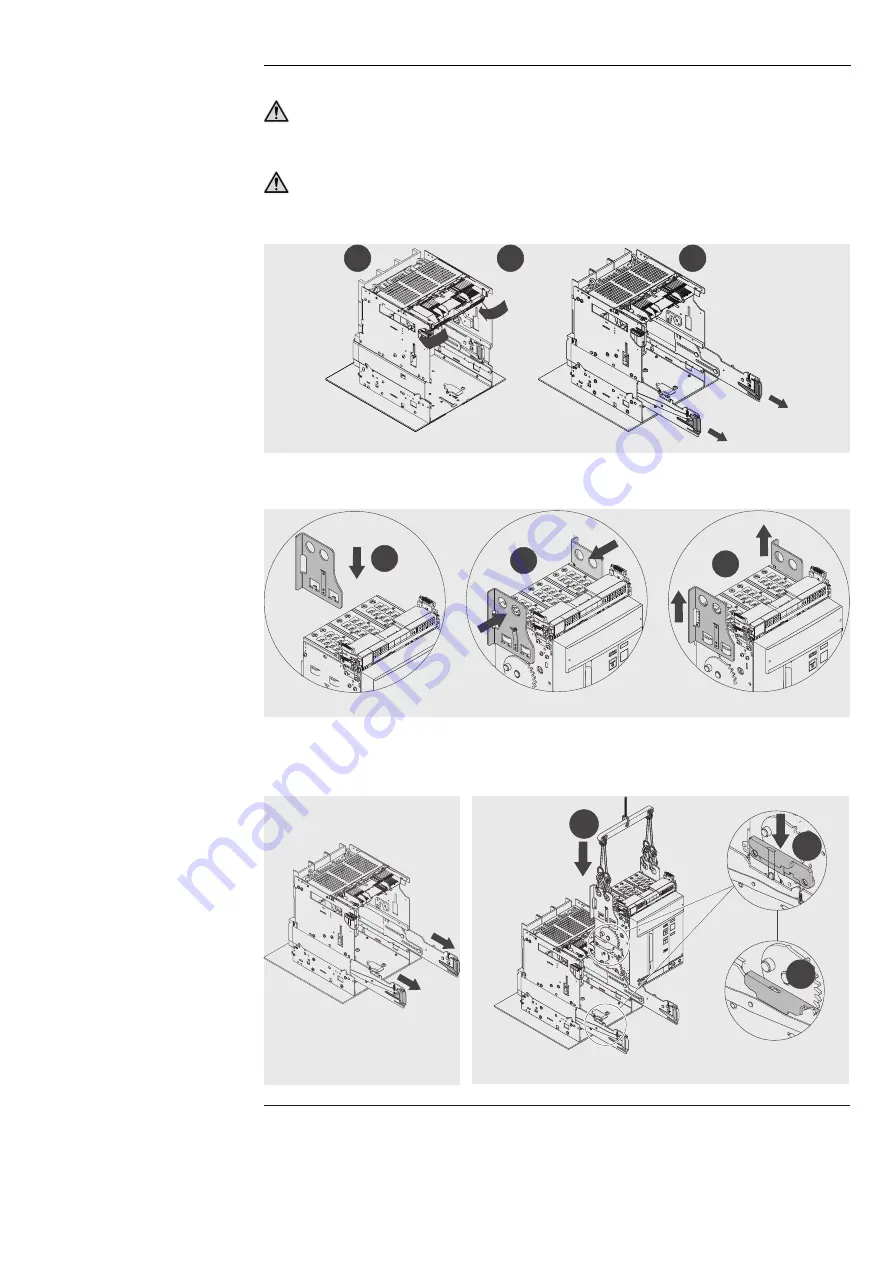

Circuit breaker racking-in/

racking-out operations

The following is the procedure for the insertion of the moving part in the fixed part:

WARNING!

•

Make sure the circuit-breaker is disconnected from all sources of energy.

•

Switch the circuit-breaker to the open position with springs discharged.

WARNING! Before proceeding, remove all equipment used during the work and remove

processing waste and materials used.

1. Turn plate through 90° before inserting the moving part.

“CLICK”

1

2

3

Figure 1

2. Position the lifting plates on the mobile part making sure that the tongue of the plates is latched

properly. See Figure 37.

3

2

1

Figure 37

3. Extract the guides of the fixed part using the appropriate levers. See Figure 38.

4. Position the moving part on the guides of the fixed part. Latch by inserting the hollow part of the side

in the latch of the guide of the fixed part See Figure 39.

Figure 38

1

2

3

Figure 39

Continued on the next page