N° Doc.

Doc. No.

Mod.

Rev.

M4379

SACE Emax

601933/003

Aparato

Apparatus

Escala

Scale

N° Pag.

Sh. No.

30/100

9.

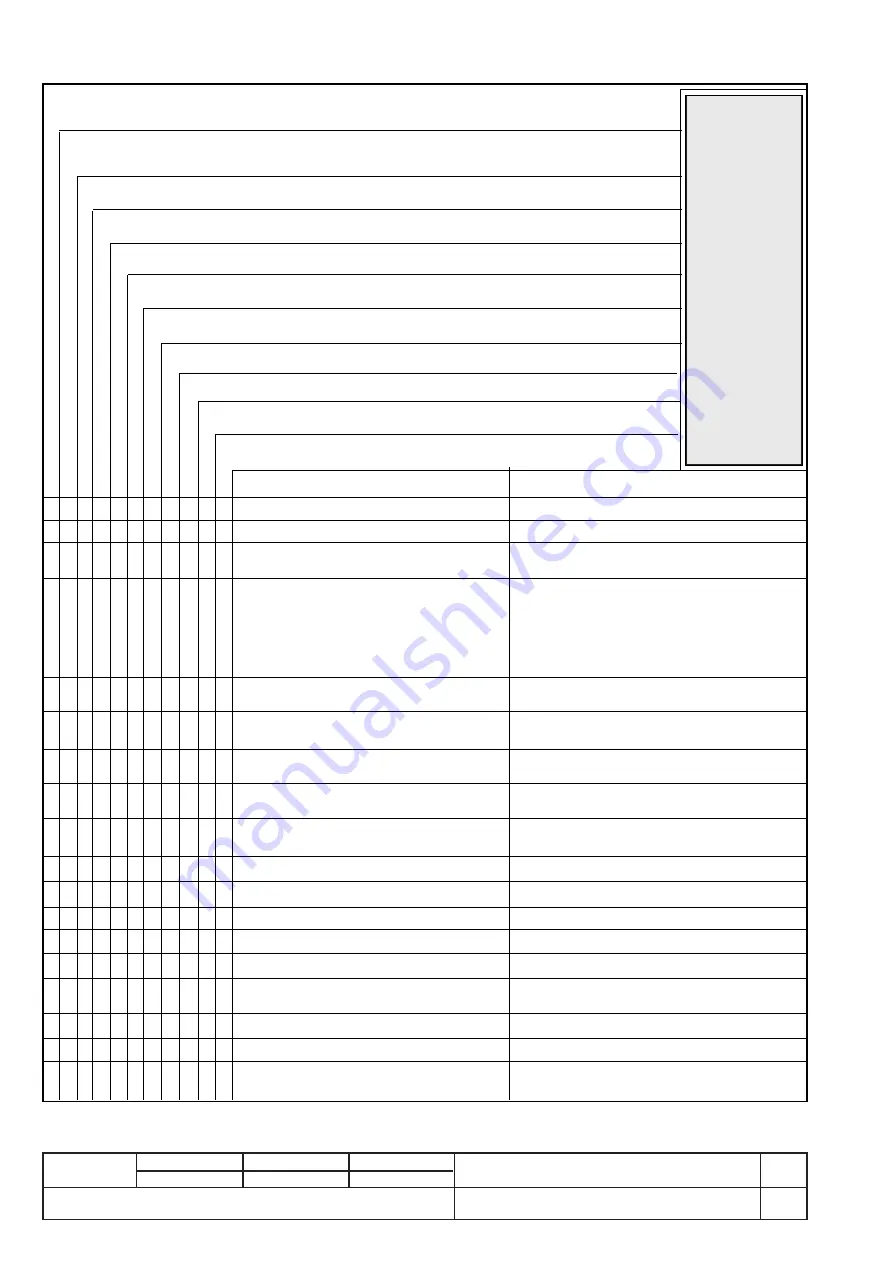

Measures to be taken for any operating anomalies

The power supply to the TEST bushes (15V dc) of the SACE PR111 release does not open the

circuit-breaker

Pressure on the TEST pushbutton of the SACE PR112 release does not make the circuit-

breaker open

Intervention of the

µ

P Fault indication on the SACE PR112 release

Lighting up of the WARNING or EMERGENCY LED on the SACE PR112 release

Release coils interrupted or burnt out, gearmotor winding interrupted

The shunt opening or closing release does not energise sufficiently

The shunt opening or closing release remains energised

The moving part does not rack into the fixed part

The moving part does not rack out of the fixed part

The circuit-breaker does not close

The circuit-breaker does not open

Checks and solutions

Check and position connector XO correctly

Replace the YO1 shunt opening release

Put the circuit-breaker out of service and check the release with

the testing apparatus

Intervene in relation to the cause: in particular, if contact wear

exceeds 80% (WARNING LED on), the circuit-breaker can

remain in service but replacement of the breaking parts must

be programmed within a short time. If contact wear reaches

100%, the circuit-breaker must be put out of service immedi-

ately. For replacement operations of the breaking parts, ask

ABB SACE.

Press the mechanical pushbutton for signalling protection

intervention

Check the state of the contacts in series with the release circuit

Measure the voltage: it must not be less than 85% of the rated

voltage

Check the rating plate voltage of the releases

Check connections, fuses, interlocks, protection circuit-break-

ers and consent contacts

Check tightening of the screws which connect the wires

Check the connections with the relative key diagram

Replace the coils

Operate manually; if the fault persists, ask ABB SACE

Insert the key and turn it

Complete the operation

Check the relative power supply circuit

Check the power supply circuit

See paragraph 7.3

• •

• •

• •

•

•

•

•

•

• •

•

•

• •

•

•

•

•

•

•

•

•

•

• •

Possible causes

XO connector not connected correctly

Coil of the YO1 shunt opening release interrupted

Fault in the electronic circuits of the microprocessor-based

release

The possible causes for intervention are listed in part B of

the manual

Protections not recovered

Control or consent contacts locked in closure

Power supply voltage of the auxiliary circuits too low

Power supply voltage different from the one indicated on the

rating plate of these releases

Switching circuit faulty

Wire tightening screws loose

Incorrect electrical connections in the power supply circuit

Release coils interrupted

Operating mechanism blocked

Key not inserted in the operating mechanism Key lock

Circuit-breaker in intermediate position between connected

and withdrawn

Undervoltage release not energised

Shunt opening release remains energised

Racking-in or racking-out operation not carried out correctly

•

•

•

Anomalies

•

•

•

•

• •