1SDH002031A1002 ECN000092998 Rev. B

SACE Tmax XT2

– XT4 | 17

8 - Maintenance and malfunction identification

Introduction

The correct maintenance of the unit and connected devices ensures proper operation over time.

Maintenance operations must be carried out by expert personnel (see "Recipients

accordance with safety regulations (see “Safety requirements” on page 5) and the maintenance

program.

If there are anomalies or malfunctions it is necessary to identify the cause and eliminate it before

continuing use of the unit.

CAUTION! The identification of malfunctions must be done only by expert

electricians (IEV 195-04-01: person with relevant education and experience to

enable him or her to perceive risks and to avoid hazards which electricity can

create). In fact, it may be necessary to carry out isolation and dielectric tests on

a part or all of the installation.

Checks and

general cleaning

Perform the following checks:

1.

Make sure Ekip Touch is clean, removing dust and any traces of other materials using dry,

clean rags (if necessary use mild detergents; for excessive dirt a laminate thinner like

Henkel 273471 or Chemma 18 or equivalent can be used).

2.

Make sure that there are no foreign objects near connectors or terminals.

Check

Ekip Touch

Perform the checks listed in the chapter Startup on page 14, also checking the status of wiring

and accessory modules:

Alarm check

Check for presence and connection of modules (internal and external)

Check zone selectivity connections

Check the

MOE-E

energy storage controller

Check

AUP

circuit breaker status, for the removable version of the CB

NOTE: the limitations and the notes for each point in the respective paragraphs are valid

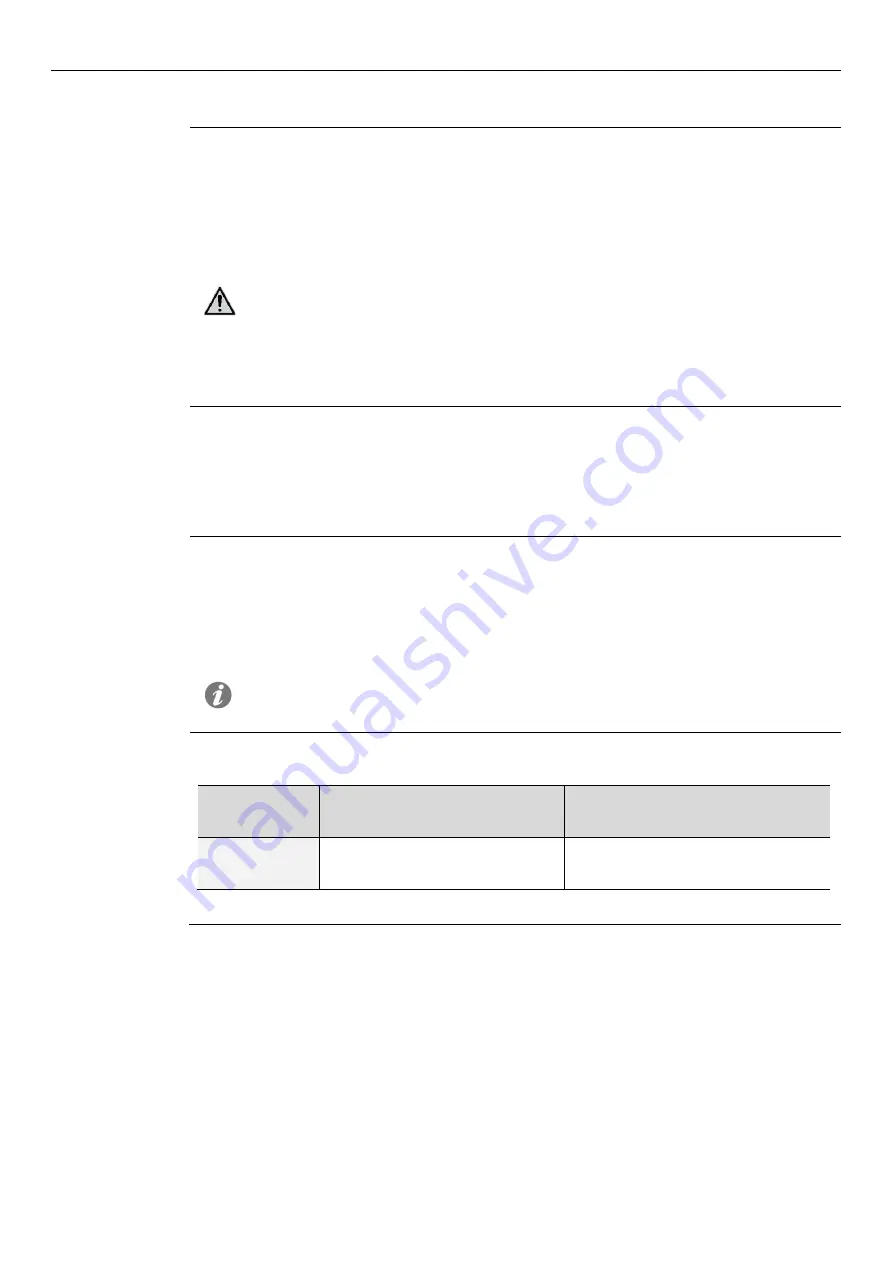

Maintenance

program

The Ekip Touch maintenance program is carried out with varying frequency depending on the

installation environment:

Standard environments

Dusty environments

(measured dust level > 1 mg/m3)

Maintenance

frequency

One year or 2000 maneuvers or

after a short circuit

Six months or 1000 maneuvers or

after a short circuit

Summary of Contents for SACE Tmax XT2

Page 84: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 84 L curve Ekip M Touch S curve t k I2 ...

Page 86: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 86 G curve t k I2 G curve t k ...

Page 87: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 87 IU curve UV curve UV2 curve ...

Page 88: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 88 OV curve OV2 curve VU curve ...

Page 89: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 89 S V curve S2 V curve RV curve ...

Page 90: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 90 UF curve UF2 curve OF curve OF2 curve ...

Page 91: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 91 RP curve D curve ...

Page 92: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 92 OQ curve OP curve ...

Page 93: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 93 UP curve RQ curve ...

Page 94: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 94 ROCOF curve R JAM curve R STALL ...

Page 95: ...1SDH002031A1002 ECN000092998 Rev B SACE Tmax XT2 XT4 95 UC curve ...