18

Programming

The parameter values are stored in the unit in a

non-volatile EEPROM memory. Thus the set-

ting of parameter values can be performed and

changed by means of the push-buttons on the

front panel or via the serial communication using

e.g. the SMS 010 software. This means that the

annunciator unit is fully field-programmable.

For connecting a PC directly to the serial inter-

face of the unit (for parameterization) the cables

SPA-ZP 6A3 and SPA-ZP 21A are used.

The entry to the parameter memory can be

blocked by means of a plug selector which is

located on the PCB right behind the front panel,

see figure 31 on page 27.

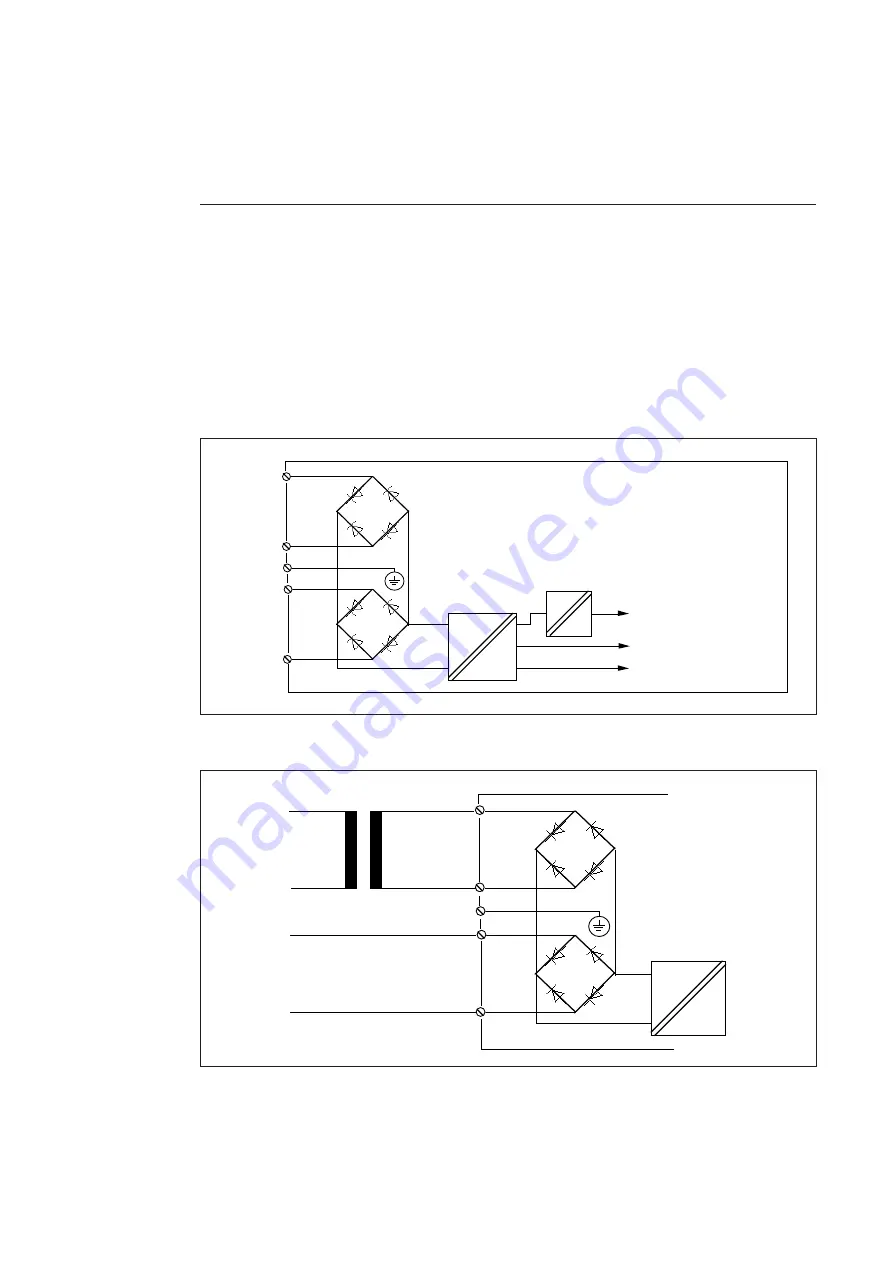

Fig. 18. Example of double power supply arrangement. Supply 1: 220 V AC with an isolating

transformer 20 VA, 220 V/220 V. Supply 2: 110 V DC supply.

Auxiliary power

supply system

The plug-in power supply module of the an-

nunciator unit is specified for supply voltage

within the range of 80...265 V AC or DC

(SPGU 240A1) or 18...80 V DC (SPGU 48B2).

The annunciator unit is equipped with one

power supply module but with two identical

supply voltage inputs (figure 17). Generally

only one of the inputs is used, but the annuncia-

tor can be supplied from two sources. It must,

however, be noticed that the two supply inputs

are galvanically connected. Thus, in case two

supplies are used, it is recommended that the

two supply sources are galvanically isolated. If

an ac supply is used, an isolating transformer can

be installed to provide the galvanic separation

(figure 18).

The insulation level between the supply source

and the electronics as well as between the field

contact circuits and the electronics is 2 kV, 50

Hz, 1 min.

Fig. 17. Principle diagram for the power supply system.

Field contact supply 48 V -

Logic supply 8 V-

Relay supply 24 V -

20

21

22

23

24

Supply 1

Supply 2

SPGU

20

21

22

23

24

Supply 1

Supply 2

220 VAC

110 VDC

SACO 16D3

SPGU