20

SAFERING XT/SAFEPLUS XT

SafeRing XT/SafePlus XT is available for a wide range of

installations and applications in order to secure the highest

safety for operators.

Switchgears are designed and type-tested for internal arc

classification according to the following configurations:

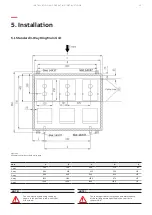

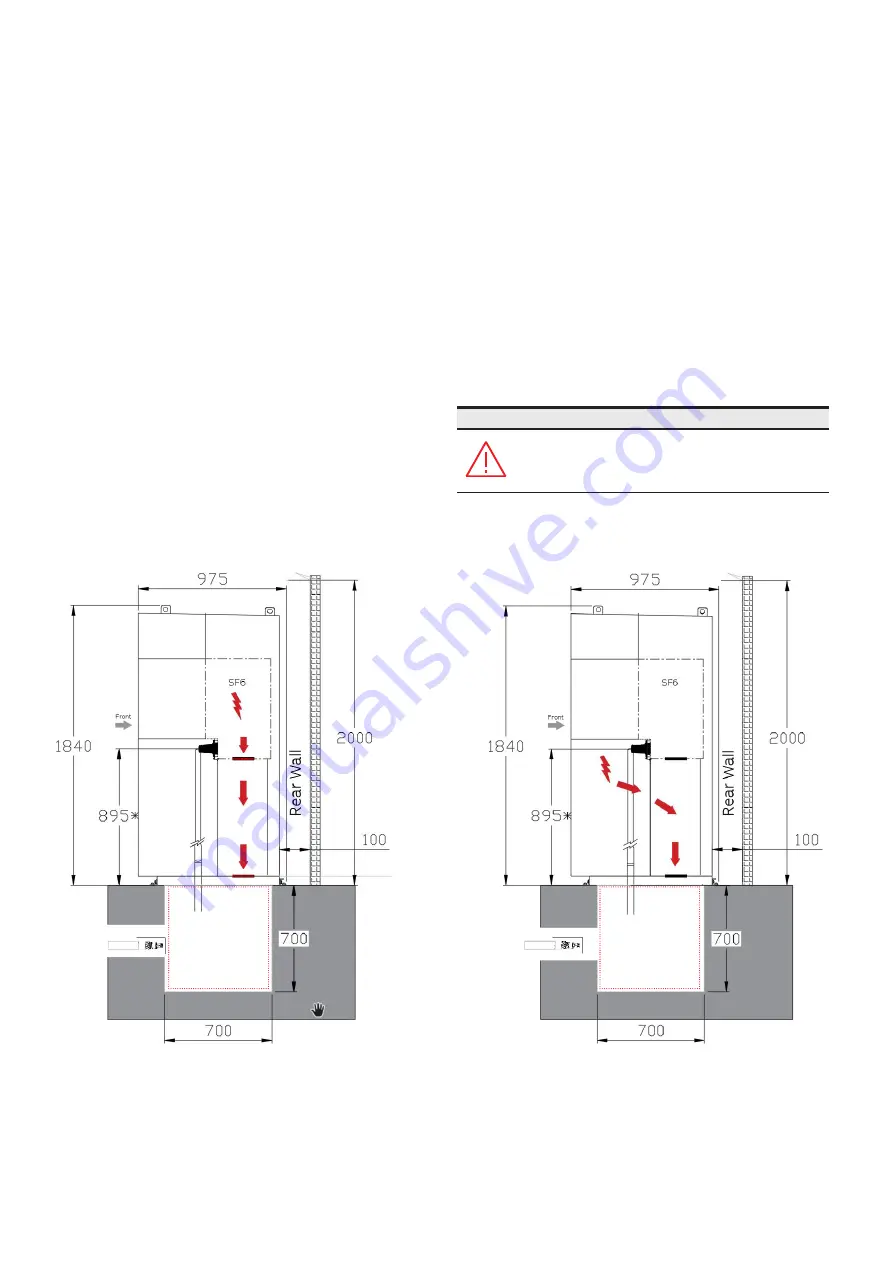

7.1 IAC AFLR

Downwards ventilation with

ventilation down to the cable

trench/floor beneath.

With this setup, hot gases and pressure are evacuated

downwards in the cavity in the floor beneath the switchgear.

Hot gases are led to the cable trench by means of a bottom

flap installed on the bottom side of the switchgear, forcing

the hot gases down during an arc fault. The switchgear

must be arranged as instructed according to the basic

parameters below.

Basic parameters of set-up:

• IAC AFLR up to 10 kA / 0.1s & 21kA /1s

• Minimum height of ceiling: 3000 mm

• Recommended distance to Rear/Lateral wall:

- 800 mm with accessible Rear/Lateral side

- 100 mm recommended for non-accessible Rear/

Lateral side.

- 700mm Minimum height of the cable trench

- 700mm Minimum depth of the cable trench

*Distance from ground level

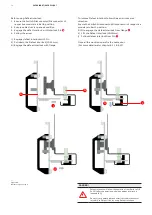

7.2 Non-arc proof version

The non-arc proof version of the metering module is not

verified for any of the IAC-classes. In the highly unlikely

event of an internal arc fault in the switchgear, hot gases

and pressure could evacuate randomly in any direction at

any place of enclosure.

• Switchgear needs to be installed and fixed to the floor

(see Chapter 5).

CAUTION!

Do not to block red dotted highlighted area as it is the

passage for internal arc fumes/gases.

—

Figure 7.2

Arc/hot gases flow- tank

—

Figure 7.3

Arc/hot gases flow- cable compartment