25

I N S TA L L AT I O N A N D O P ER AT I N G I N S T R U C T I O N S

8.2 Cable connection

The connection of the HV-cables is made by cable bushings.

The bushings are made of cast resin epoxy with molded in

conductors. In addition, a screen is molded in, for

controlling the electrical field. The screen is also used as the

main capacitor supplying the voltage indicating systems.

The bushings are designed according to CENELEC EN 50181,

EDF HN 52-S-61 and IEC 60137 and type Interface C (400

series with M16 bolted contact, In = 630A). All bushings are

situated in the same height from the floor and are protected

by the cable cover.

Before/while doing installation and cabling related work,

following points to be used as check points to avoid

equipment damage and serious personnel injury.

Important check points!!

• Before starting cabling work, RMU frame/body is

earthed

• Cable bushings epoxy surfaces thoroughly lubricated

with the silicone grease (supplied) before inserting

insulating boots

•

1

Cable lug suitable to 25 mm diameter copper rod of

cable bushings

•

1

Cable lug directly in contact to cable bushing copper

face

•

1

Termination joints properly tightened with torques (by

calibrated tool)

•

2

Installation instructions and procedure suggested by

cable manufacturer strictly followed and all possible

compatibility issues between insulating components

checked

• Assembly and installation of stress control tubes done

properly

• Where cable not connected, earthing switch locked in

closed position or the bushings fitted with dead end

receptacles before the unit is energized

• All cable phase connections match with phase positions/

sequence

•

3

Cables correctly clamped and gland area sealed properly

to avoid dust/verm entry

• All 3 cables in 3 core terminations cut and adjusted

properly so that cable lug hole and M16 copper hole of

cable bushing is concentric

• In case of a cable length mismatch, no tool or crooked

method employed by which cable bushing are stressed

• Dust or other particles accumulated because of improper

storage or site conditions thoroughly cleaned and all

cable boxes clean from inside

• Cable earthing to be done to the earthing points

provided close to respective cable boxes.

• Before and after Termination ensure there is no stress of

the cable on the bushings.

• It is preferred and recommended to clamp the cable

with the clamp provided in unit before starting the cable

termination.

1

Failure to do this can result in prolonged heat generation at the particular cable

joint and subsequently failure of cable insulation and resulting in a flashover

phenomenon

2

It is recommended to have cable terminations kits and boots/elbows from the

same manufacturer so as to avoid compatibility Issues. Due to incorrect size and

mismatch of insulating components long term dielectric withstand cannot be

guaranteed.

3

This is to ensure stress free connection and to avoid entry of dust/small creatures

into the cable compartment, which may severely reduce dielectric performance.

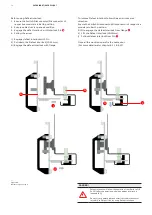

Option 1:

Heat shrink type cable termination using special insulated

terminal protectors as shown in picture below.

CT’s

—

Figure 8.7

CT and cable termination details

—

Figure 8.8

cable termination details

Center Of Cable

Bushing

HVOT - Insulating Tube

Stress Control

Tube

Black Tube-2

Copper

Screen

Black Tube-1

Black Tube-1

(Trifurcation Boot)

Copper

Braid

Binding Wire

Copper

Mesh

Cable Earthing

Braid

Armour