22

WARNING

Replenishment of SF

6

-gas in SafeRing/SafePlus

Potential risk!

Operators must be trained and qualified for

SF

6

-gas handling

The following equipment is needed: SF

6

-gas bottle with

manometer and reduction valve, bottle for recovery of

SF

6

/air mixture, adapter and pressure measuring device. It is

important that the pressure measuring device shows absolute

pressure. If you have a pressure measuring device showing

over-pressure, please contact ABB for instructions

(NHP 408025).

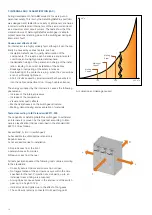

1. Remove the front cover and if possible the top cover.

Unscrew the pressure indicator by unscrewing the hexagon

nut as shown on the figure at the right.

2. Screw the adapter to the valve. The tightening torque is

max 45 Nm.

3. Before connecting the hose from the gas bottle to the

adapter, the air in the hose must be removed by running

SF

6

-gas through the hose. The SF

6

-gas must be recovered.

4. When gas is flowing into the RMU/switchgear, the mano-

meter on the gas bottle has to be observed. When it shows

1,4 bar absolute at ambient temperature 20° Celsius, the

gas filling must be stopped. See table for filling pressure on

next page.

13. PRESSURE INDICATOR

SafeRing / SafePlus is usually supplied with a pressure indi-

cator in the form of a manometer. Additionally, it is possible

to fit a device for an electric signal if the pressure is low. This

requires auxiliary voltage supply.

13.1 GAS PRESSURE

SafeRing / SafePlus contain SF

6

-gas with a nominal pressure

of 1,4 bar absolute at 20

o

C.

SafeRing / SafePlus are «sealed for life» and fitted with a

temperature-compensated pressure indicator.

Pointer in green area - unit has sufficient pressure.

Pointer in red area - pressure is too low.

WARNING

Operation when pressure is too low (pointer in

red area):

If pointer is in red area, the operation of the switch-

gear can not be done under live conditions (voltage

on). SF

6

-gas needs to be topped up according to

instruction and the filling table on next page before

operation can be done under live conditions.

For more detailed description, see instruction ma-

nual 1VDD201603

5. Remove the filling hose and connect the pressure device to

check the pressure inside the RMU/switchgear.

6. When the correct pressure of 1,4 bar absolute is obtained,

remove the adapter, check that the sealing between the

pressure indicator and the valve is smooth and clean, and

screw the pressure indicator to the RMU/ switchgear with

tightening torque max 45 Nm as shown below.

Note! Screw/unscrew on this hexagonal

nut only. The pressure indicator can be

dismounted from the switchgear with-

out SF

6

leakage from the SF

6

tank

Spring-loaded

valve

Air

SF

6

CAUTION