31

100%

Transformer rating (kVA)

Fuse-link

rated

voltage

U

n

(kV)

25

50

75

100

125

160

200

250

315

400

500

630

800

1000

1250

1600

7,2 kV

3

16

25

25

40

40

50

50

80

100

125

160

160

3,3

16

25

25

40

40

50

50

63

80

100

125

160

4,15

10

16

25

25

40

40

50

50

63

80

100

125

160

5

10

16

25

25

25

40

40

50

50

63

80

100

160

160

5,5

6

16

16

25

25

25

40

50

50

63

80

100

125

160

6

6

16

16

25

25

25

40

40

50

50

80

100

125

160

160

6,6

6

16

16

25

25

25

40

40

50

50

63

80

100

125

160

10

6

10

10

16

16

25

25

25

40

40

50

50

80

80

125

125

12 kV

11

6

6

10

16

16

25

25

25

25

40

50

50

63

80

100

125

12

6

6

10

16

16

16

25

25

25

40

40

50

63

80

100

125

13,8

6

6

10

10

16

16

25

25

25

25

40

50

50

63

80

100

17,5 kV

15

6

6

10

10

16

16

16

25

25

25

40

40

50

63

80

100

17,5

6

6

6

10

10

16

16

16

25

25

25

40

50

50

63

80

20

6

6

6

10

10

16

16

16

25

25

25

40

40

50

63

63

24 kV

22

6

6

6

6

10

10

16

16

16

25

25

25

40

50

50

63

24

6

6

6

6

10

10

16

16

16

25

25

25

40

40

50

63

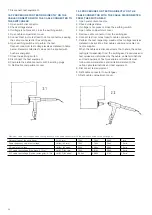

15.6 FUSE SELECTION TABLE

15.6.1 FUSE SELECTION TABLE - CEF

- The table is based on using fuses type ABB CEF

- Normal operating conditions with no overload

- Ambient temperature -25

o

C - +40

o

C

120%

Transformer rating (kVA)

Fuse-link

rated

voltage

U

n

(kV)

25

50

75

100

125

160

200

250

315

400

500

630

800

1000

1250

1600

7,2 kV

3

16

25

25

40

40

50

63

80

100

125

160

3,3

16

25

25

40

40

50

63

80

80

100

125

4,15

10

16

25

25

40

40

50

63

80

80

100

125

5

10

16

25

25

25

40

40

50

63

80

80

125

160

5,5

6

16

16

25

25

25

40

50

50

80

80

100

125

160

6

6

16

16

25

25

25

40

40

50

63

80

100

125

160

6,6

6

16

16

25

25

25

40

40

50

63

80

80

100

125

10

6

10

10

16

16

25

25

25

40

40

50

63

80

80

125

12 kV

11

6

6

10

16

16

25

25

25

25

40

50

50

80

80

100

125

12

6

6

10

16

16

16

25

25

25

40

40

50

63

80

100

125

13,8

6

6

10

10

16

16

25

25

25

25

40

50

50

80

80

100

17,5 kV

15

6

6

10

10

16

16

16

25

25

25

40

40

50

63

80

100

17,5

6

6

6

10

10

16

16

16

25

25

25

40

50

50

63

80

20

6

6

6

10

10

16

16

16

25

25

25

40

40

50

63

80

24 kV

22

6

6

6

6

10

10

16

16

16

25

25

25

40

50

50

63

24

6

6

6

6

10

10

16

16

16

25

25

25

40

40

50

63

- The table is based on using fuses type ABB CEF

- Normal operating conditions with 20% overload

- Ambient temperature -25

o

C - +40

o

C