Mounting and installation

22

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

4.7.5

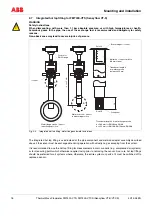

Disassembling the transducer with system in operation

– Rotate the hot tap fitting using the lock nut. (Upper stop of lock nut, with lettering 0 - CLOSE - ZU must be

visible; see detail A in Fig. 4-4).

– Disconnect transducer electrically according to instructions manual.

– Remove the nuts for the covers and carefully release the screws securing the transducer according to the fol-

lowing instructions.

DANGER

The mounting screws of the Sensyflow transducer may only be released when the hot tap fitting is in

disassembly position. Do not release the mounting screws when the fitting is in measuring position.

WARNING

Depending on design, a small amount of process gas (some cm

3

) may be released when disassembling

the transducer. For toxic or explosive gases, make sure that sufficient ventilation is provided.

WARNING

If when releasing the mounting screws you notice a large amount of gas escaping, the activities must

be stopped and screws retightened. Check whether the fitting is actually in disassembly position.

If it is positioned properly, disassembly of the transducer can only be performed after emptying and, if

necessary, cleaning the pipeline (defective hot tap fitting, see Maintenance).

– Remove the transducer from the hot tap fitting. Warning: Do not tip to the side.

4.7.6

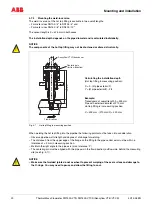

Maintenance

After approx. 100 installation and disassembly procedures, the transducer O-ring gaskets for the PN 16 hot tap

fitting must be replaced. When working with dusty, abrasive or aggressive measured media, it may be necessary

to replace these more frequently.

Only ABB Service or qualified personnel of the operator is authorized to replace O-ring gaskets. For the latter

case, the warranty is no longer valid for ABB.

Fig. 4-11 shows the individual parts of the hot tap fitting:

Fig. 4-11

Components of the integrated hot tap fitting

!

!

!

Covers (3)

Trans-

ducer (4)

Guide

tube (2)

Pipe

compo-

nent (1)